- 7 -

● Voltage and Current Hazards

It is very dangerous to turn on the power without prior notice to workers

maintaining the system. Never turn on the power unexpectedly. Careless

supply of power will injure or kill workers due to operating automation

or electric shock. Give a warning to other workers, and do not permit

outsiders to turn on the power.

The control system of this system operates on 380VAC(varies with

specification). The energized part and the current-carrying part are

sealed with the door panel under the normal operation, and the

operator is not exposed to voltage and current hazards. It is only when

the system is operated or maintained keeping the door panel open that

the operator is exposed to such hazards.

● Danger of Electric Shock

When you touch energized parts or current carrying parts will cause electric shock or

bring serious injury or death to the operator due to heat of short-circuit or scattered

objects.

• When you maintain the section supposed to be energized and carry current, make

sure that the system power is turned off. Besides that, check voltage doesn’t load

the section with voltage tester before starting a maintenance work.

• If a worker wearing metal or conductive ornaments and precious metals (ring, wrist

watch, bracelet, etc.) operates or maintain the system, such ornaments may contact

any energized parts, he or she will be damaged by electric accidents. Be sure to

remove ornaments and precious metals when operating or maintaining the system.

● Danger of Short circuit

When the earth leakage breaker is actuated and the breaker is set to OFF, or when

the fuse is found to be blown, the system may have a short-circuit.

• Turn off the power and investigate the cause, or the breaker will not only actuate

again but also electric shock will occur due to leakage.

● Emergency Off Switch (EMO Switch)

In case of an emergency stop with the EMO switch and interlock switch, the

breaker inside the system is shut off. Unless the power on the factory is turned

off, the primary side of the breaker has been still energized. So, do not touch

terminals.

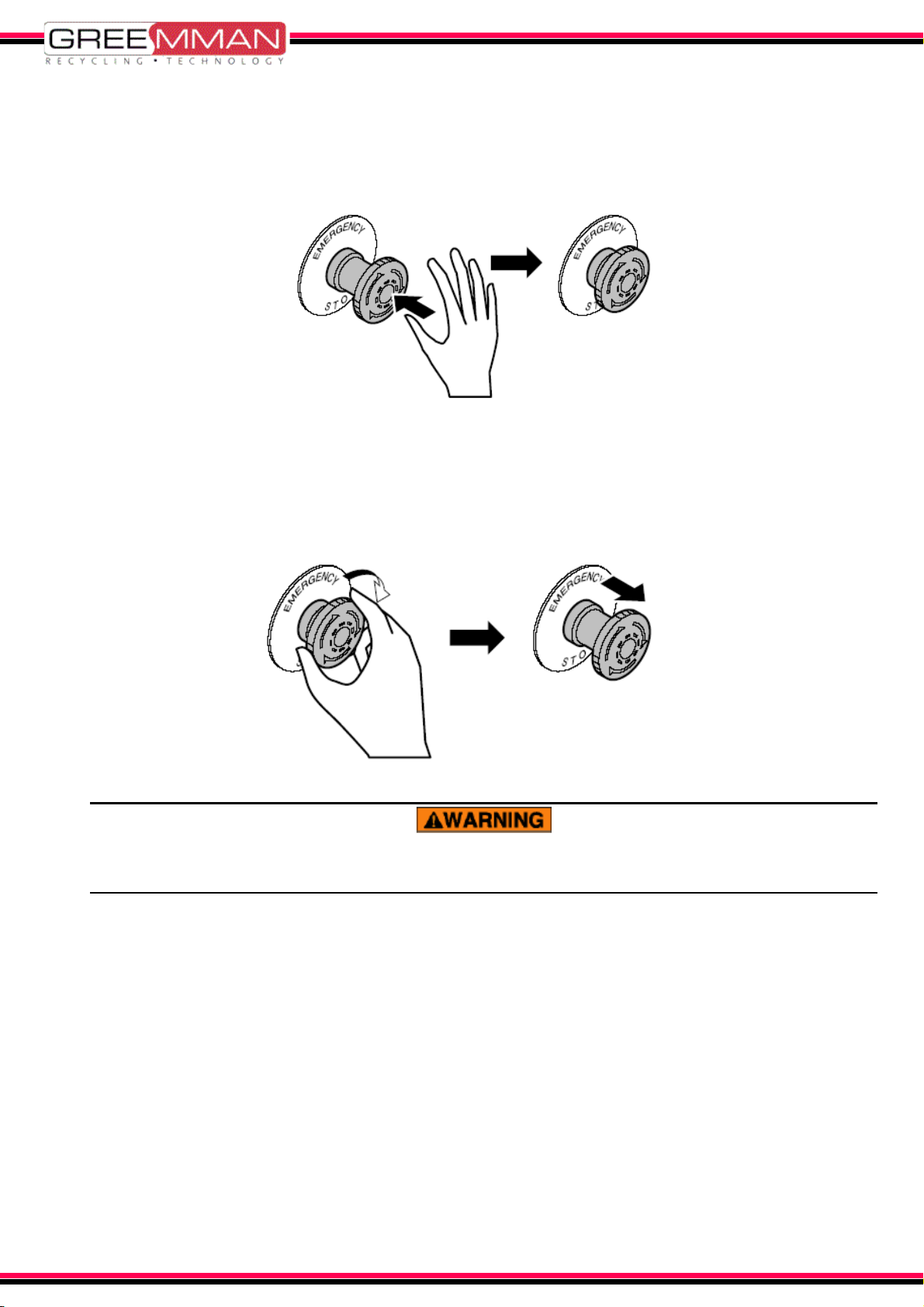

The system is fitted with an Emergency Off (EMO, Interlock) Switch. Pressing the

switch shuts off the power to the system. Before operation or maintenance work,

be sure to check the location of the EMO switch and to understand how to use it.

Check operation of the EMO switch at constant intervals.