1Introduction

1.1 About this Manual

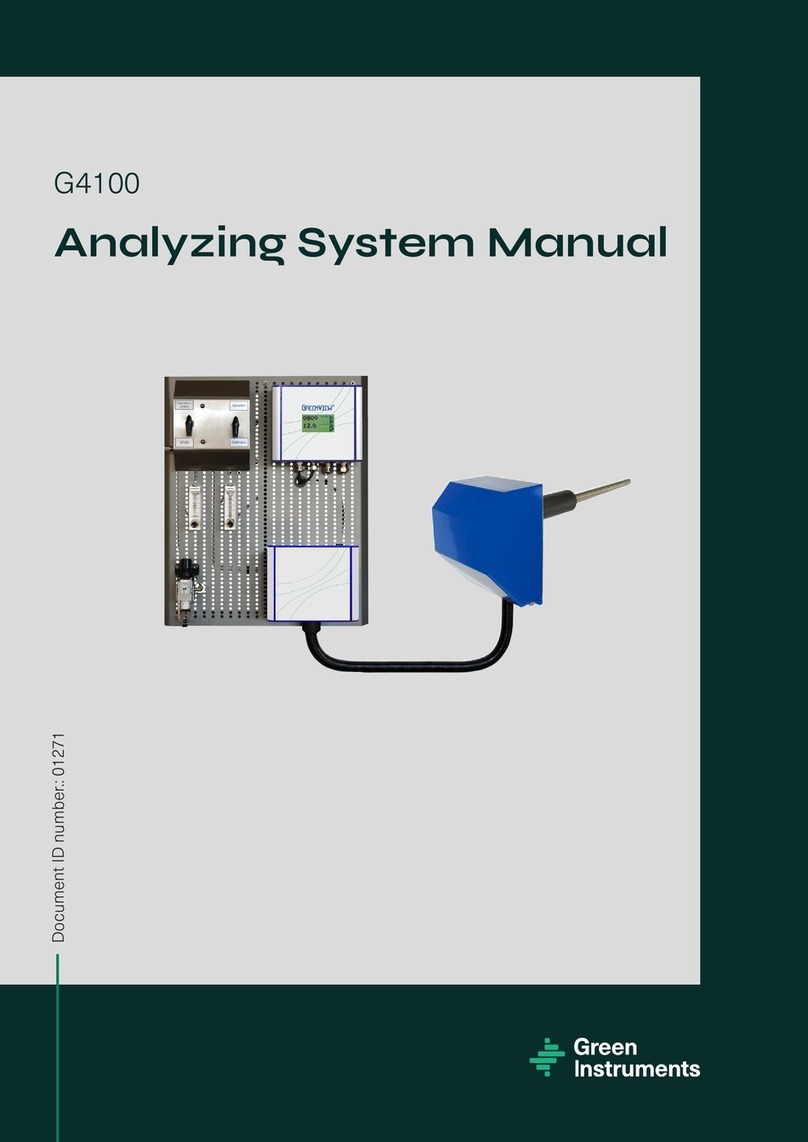

The G3621a/p Stack Gas Oxygen Analyzing System, hereafter named an SGOA System,

consists of an oxygen analyzer, an analyzing board, and a diffusion probe.

This manual contains data and instructions for the installation, operation, and mainte-

nance of the analyzing board and the SGOA System as a whole.

The instructions for installation, operation, and maintenance of the analyzers are provid-

ed in separate manuals:

The G36a Oxygen Analyzer manual (p#01245) –IP67 box

The G36p Oxygen Analyzer manual (p#01381) –panel mounted

Therefore, for the installation, operation, and maintenance of an entire SGOA System,

this manual and the concerned oxygen analyzer manual must be read carefully in their

entirety.

The instructions have been made in general terms and do not take into consideration the

existing equipment and its installation. As such, the manual is designed for the standard

G3621a/pSGOA System with Diffusion Probe.

This manual does not describe all possible situations but only the most common and

known situations and cannot replace the necessary instruction and education of the per-

sonnel.

Before operation read all instructions and warnings within this manual and associated

documentation. Improper use may cause personal injury and/or damage of equipment

and may void the warranty.

Green Instruments A/S disclaims any responsibility for damage and/or injury caused

by improper installation, use or maintenance of the equipment.

Should situations not described in this manual occur which cannot be solved in accord-

ance with normal known practice and good workmanship, the operator should contact

Green Instruments A/S for instructions.