• Recommendation!

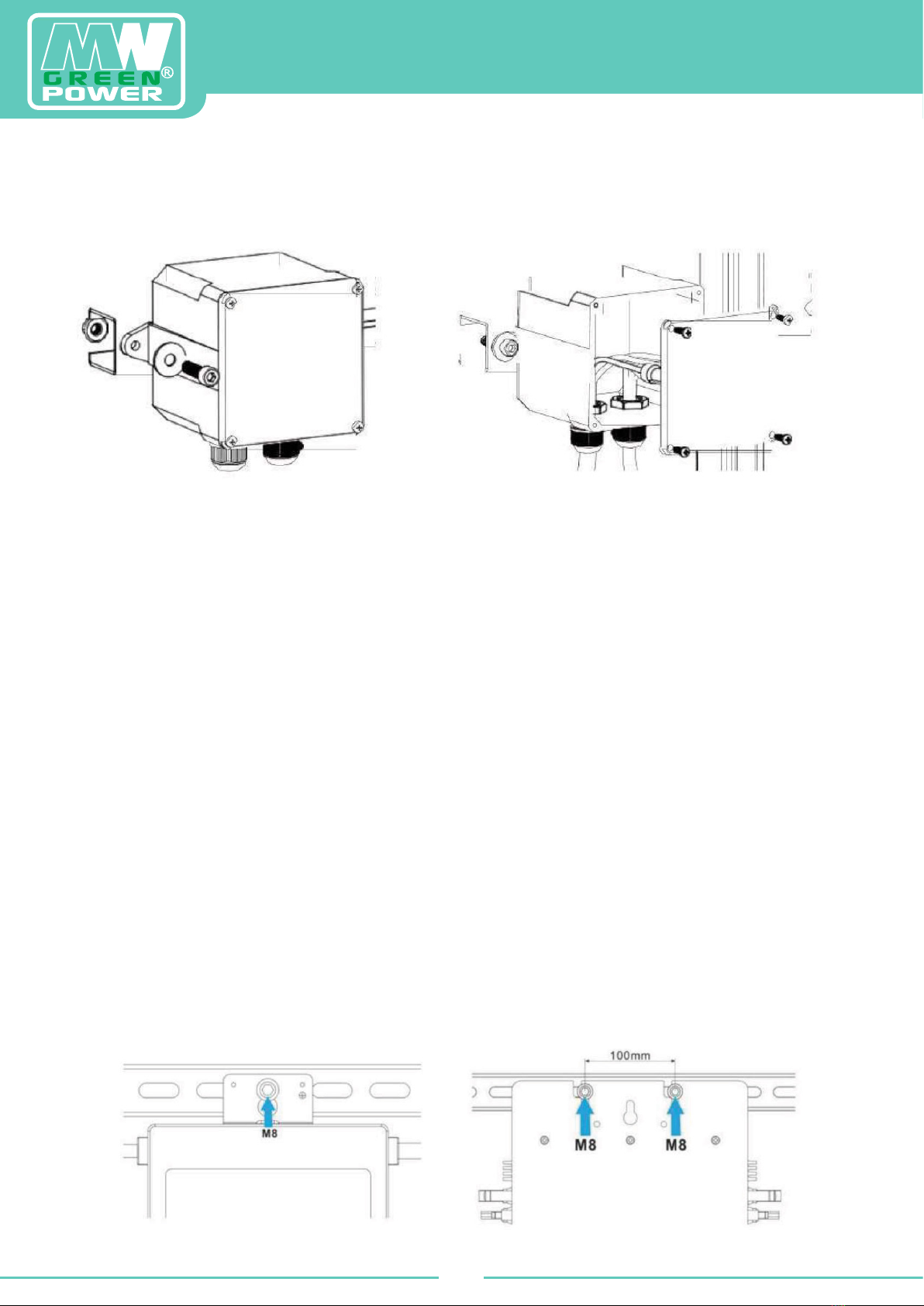

The external protective ground wire is connected to the protective ground ter-

minal of the inverter via the AC connector.

When connecting, connect the AC connector first to ensure that the inverter is

grounded, and then make the DC connection.

When disconnecting, disconnect the AC power by opening the branch circuit

breaker first, but keep the protective ground wire in the branch circuit breaker,

connect to the inverter, and then disconnect the DC inputs.

• Under no circumstances should the DC input be connected when the AC con-

nector is disconnected.

• Install isolating switching devices on the AC side of the inverter.

Radio Interference Statement

CE EMC Compliance: This equipment may comply with CE EMC, which are de-

signed to protect against harmful interference in a residential installation. This

equipment may emit radio frequency energy which can cause harmful interfe-

rence to radio communications if not installed and used in accordance with the

instructions. But there is no guarantee that interference will not occur in a par-

ticular installation. If this equipment does cause harmful interference to radio or

television reception, the following measures may solve the problems:

A) Reposition the receiving antenna and keep it away from the equipment

B) Consult the dealer or an experienced radio/TV technician for help

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

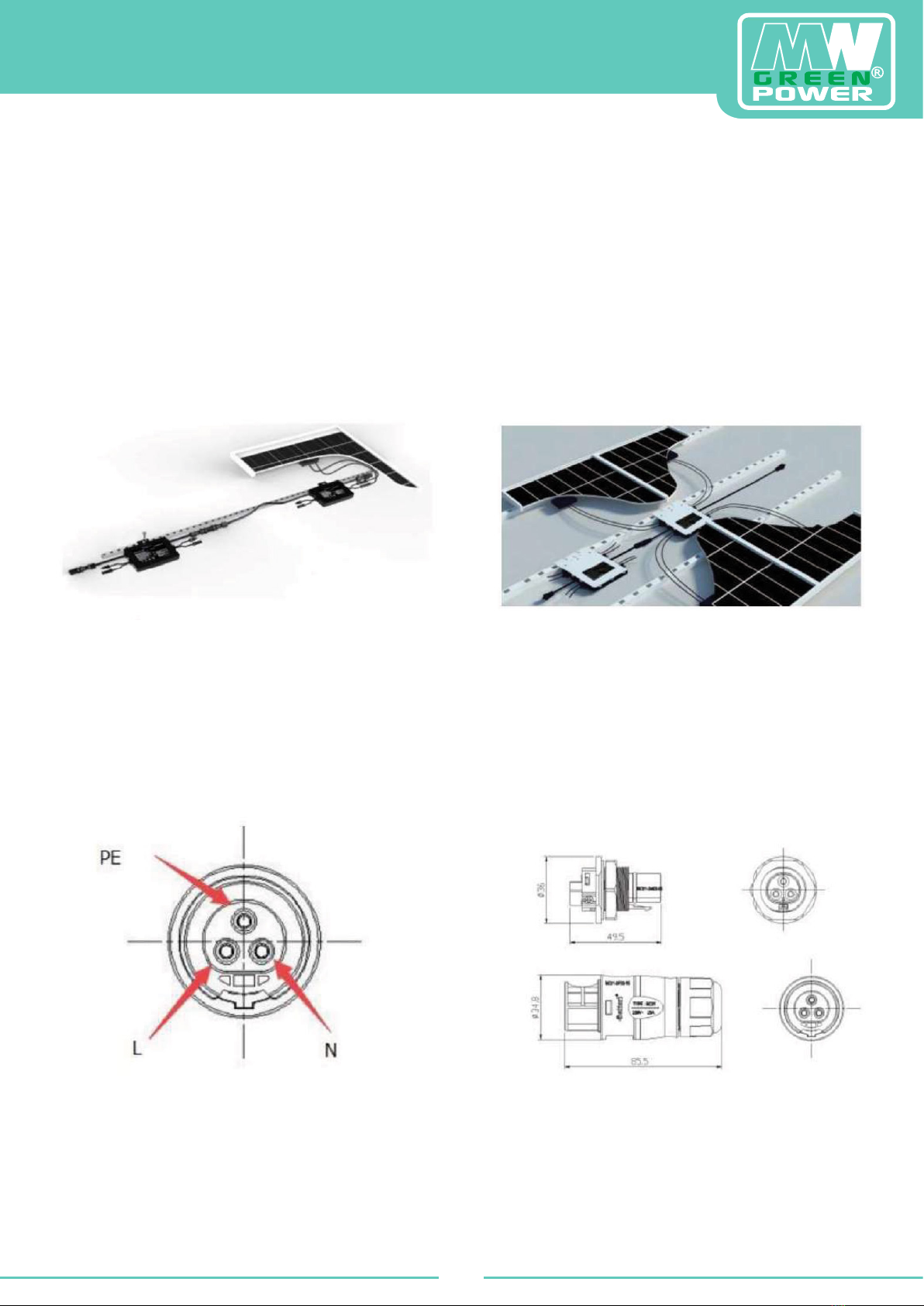

Energy Monitoring and Analysis (EMA) systems software analyzes and reports the performance

of each module based on real-time data collected by the Energy Collection Device (ECD) ga-

teway. EMA immediately detects any performance issues in the array, indicating the location

and nature of the problem and providing precise maintenance guidance, all in a user-friendly

graphical interface. Communication between the inverter and the ECD can be affected by

signal „noise” from a nearby electrical device, the distance between the inverters and the ECD,

the number of inverters supported, and other factors, so sometimes the ECD experiences a

random loss of signal or data, this is not a problem or a fault. If the ECD is not communicating

with the EMA database at all, please contact technical support.

-2-