Troubleshooting Guide

A duct heater must be installed according to the

installations instructions, wiring diagram and labeling

supplied with the heater.

Listed below are some important items when installing

an electric duct heater:

1. Never operate a duct heater without airflow.

The heater must always be interlocked with the

fan. This may be accomplished by either an

airflow switch or fan interlock relay.

2. Never operate heater without achieving at least

the minimum airflow required. Always refer to

the installation instructions and the nameplate

label to determine minimum air velocities based

on inlet air temperature. If the minimum airflow

requirements are not present the heater will not

function properly and safely

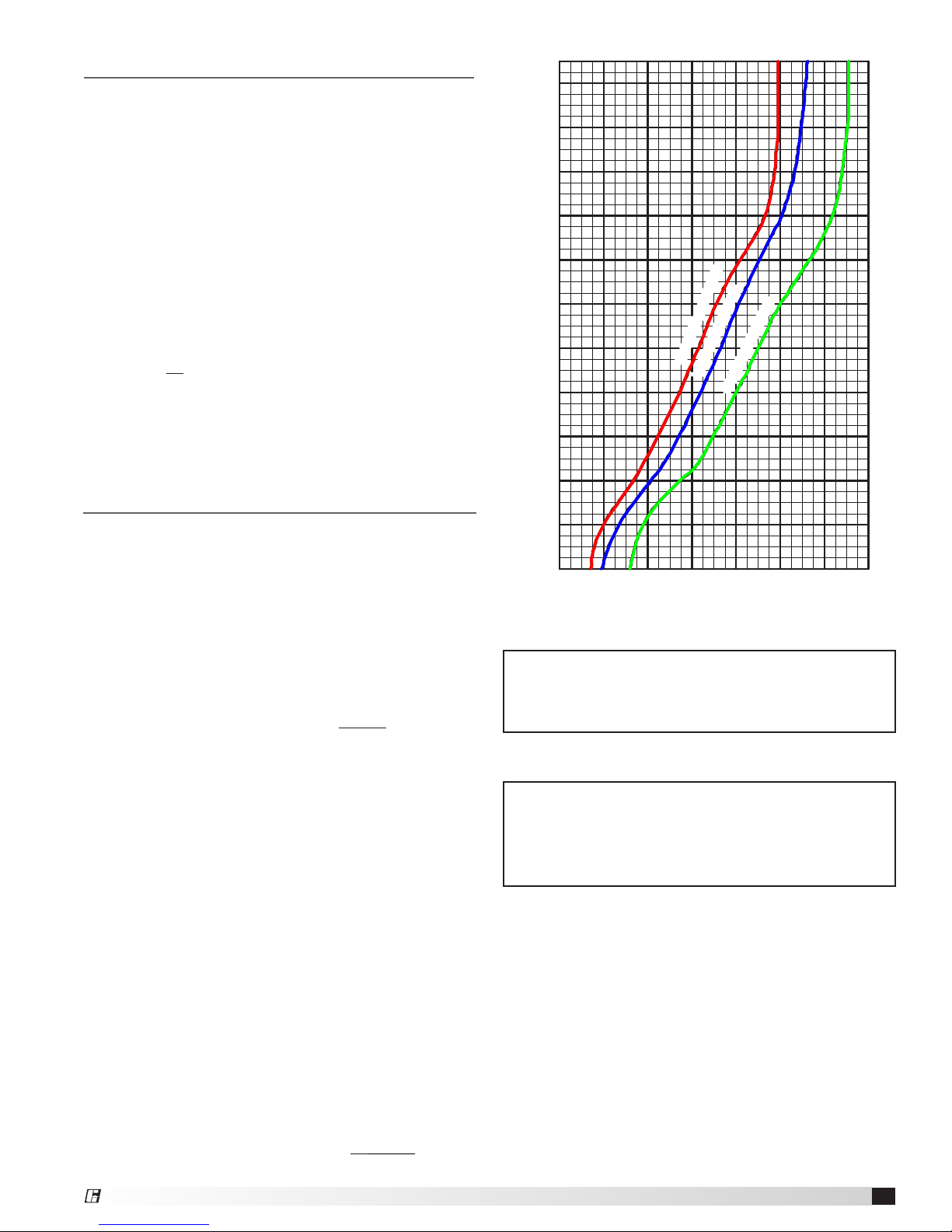

(see Figure 3).

3. Never operate the heater with uneven airflow.

The minimum airflow requirements must be

present at all points over the heater face (see

Figure 3).

4. The air must be filtered. The incoming air must

be free from all debris, combustible particles,

and hazardous vapors.

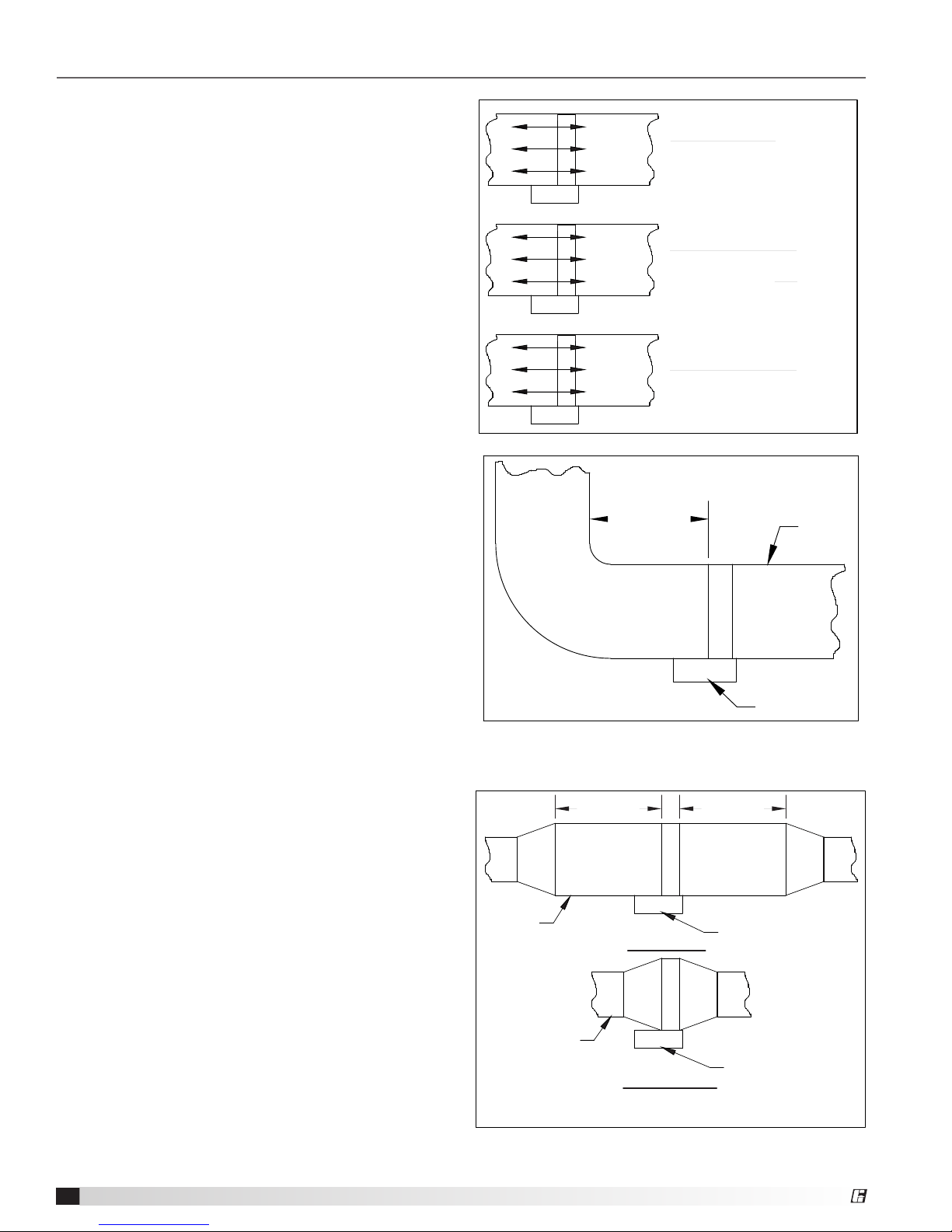

5. Locate the heater at least 24 in. from an elbow

or turn (see Figure 4).

6. Locate the heater at least 48 in. from the

following (see Figures 5-9):

• heat pump or central air

• canvas duct connector or transition

section for change in duct size.

• downstream from an air handler.

• upstream from a humidifier

• downstream from an air filter

• fan

7. Never install a standard heater into a duct with

an internal obstruction. An obstruction can

block airflow at the temperature limit controls

and element terminations. If this situation

exists, it can be corrected by using a heater

with recessed control box and reduced wrapper

size. This situation is common with internally

insulated ducts (see Figure 10).

8. Never insulate the exterior of the control box.

The control must be completely accessible and

located where ventilation can be provided at all

times (see Figure 11).

9. Never install a heater near a double blower

outlet. A heater must be installed far enough

away from a double blower outlet so that even

and proper airflow is present or separate duct

heaters placed in the duct runouts of each

blower (see Figure 12).

500 fpm

470 fpm

780 fpm

EXAMPLE: IF 780 fpm IS REQUIRED

EXAMPLE: IF 780 fpm IS REQUIRED

EXAMPLE: IF 780 fpm IS REQUIRED

CORRECT

MIN. AIRFLOW AND EVEN AIR

DISTRIBUTION ARE PRESENT

INCORRECT

MIN. AIRFLOW AND EVEN AIR

DISTRIBUTION ARENOT PRESENT

INCORRECT

MIN. AIRFLOW IS NOT PRESENT

FIG. 3

470 fpm

470 fpm

780 fpm

780 fpm

780 fpm

780 fpm

FIG. 4

FIG. 5

Heat Pump or Air Conditioner

24" MIN.

48" MIN.

HEAT PUMP OR

AIR CONDITIONER

HEATER

DUCT

INCORRECT

CORRECT

FIG. 5

Transition Change

HEATER

48" MIN. 48" MIN.

HEATER

DUCT

DUCT

6Electric Duct Heaters