6.AMD-xx-TD series more than one section high will be

shipped separately in individual sleeves. Using the provided

RJ-45 cable connect the bottom probe on the top section to

the top probe on the bottom section. The bottom section has

the transmitter mounted to it.

Do not twist

or bow. Mount

damper plumb

in the opening.

AB

AF = BE

AB = CD

CD

EF

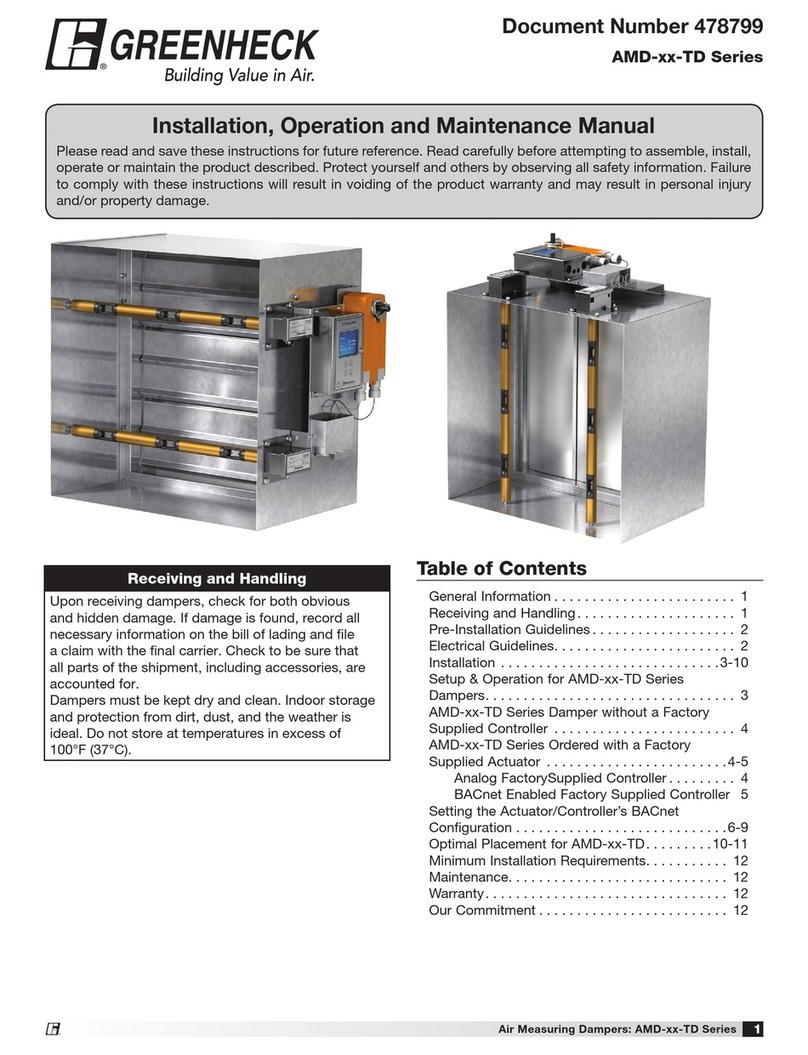

Installation - Failure to follow instructions will

void all warranties

1. Ensure the AMD-XX-TD series dampers is mounted

with measurement probes upstream of the damper.

2. Your duct opening or opening square should measure

1/4 inch (6mm) larger than damper dimension and

should be straight and level.

3. Use shims between damper frame and duct opening

or opening space to prevent distortion of frame by

fasteners holding it in place. Brace at every horizontal

mullion and vertically brace at every 8 feet (2.4m) of

damper width for strength. Dampers in high velocity

(2000 fpm [610m per second]) may require more

bracing.

NOTE: Greenheck dampers are specifically designed

and engineered for structural integrity based on model

and conditions. Attachment, framing, mating flanges,

and anchoring of damper assemblies into openings,

ductwork, or walls is the responsibility of the installer.

Design calculations for these retaining and supporting

members should be determined by field engineers for

that particular installation.

4.Individual damper sections, as well as entire multiple

section assemblies must be completely square and

free from racking, twisting, or bending. Measure

diagonally from upper corners to opposite lower

corners of each section.

5.Damper blades, axles, and linkage must operate

without binding. Before system operation, you can

cycle dampers after installation to assure proper

operation. On multiple section assemblies all sections

should open and close simultaneously.

Setup and Operation for AMD-xx-TD

Series Damper

All AMD-xx-TD’s are supplied with a Vari-Green®

airflow rate transmitter that is factory wired to one or

more Vari-Green airflow measurement probe(s). The

transmitter has been configured at the factory with

customer supplied parameters. For normal applications

the transmitter’s configuration should not need to be

modified in the field. However, if field configuration is

necessary please reference the Vari-Green transmitter

Installation, Operation, and Maintenance Manual

available at www.greenheck.com.

Once electrical power is applied, the transmitter will

go through a standard start-up sequence during which

it will identify and enable each airflow sensor. This will

take approximately 25 seconds. Once the start-up

sequence has been complete, the transmitter’s display

will show the measured volumetric airflow rate, velocity,

and ambient air temperature (see below). Under normal

operation, a blinking green dot in the upper right corner

of the display signifies that the processor is functioning

correctly, and two flashing arrows indicate that the

sensor(s) and transmitter are communicating normally.

You can order AMD-xx-TD’s with or without a factory

supplied controller. When a factory supplied controller

is ordered, the controller can be configured for either

analog operation or operation via a BACnet MS/TP

connection. Setup and operation for these different

options are described on the following pages.

AMD-xx-TD Series 3