4

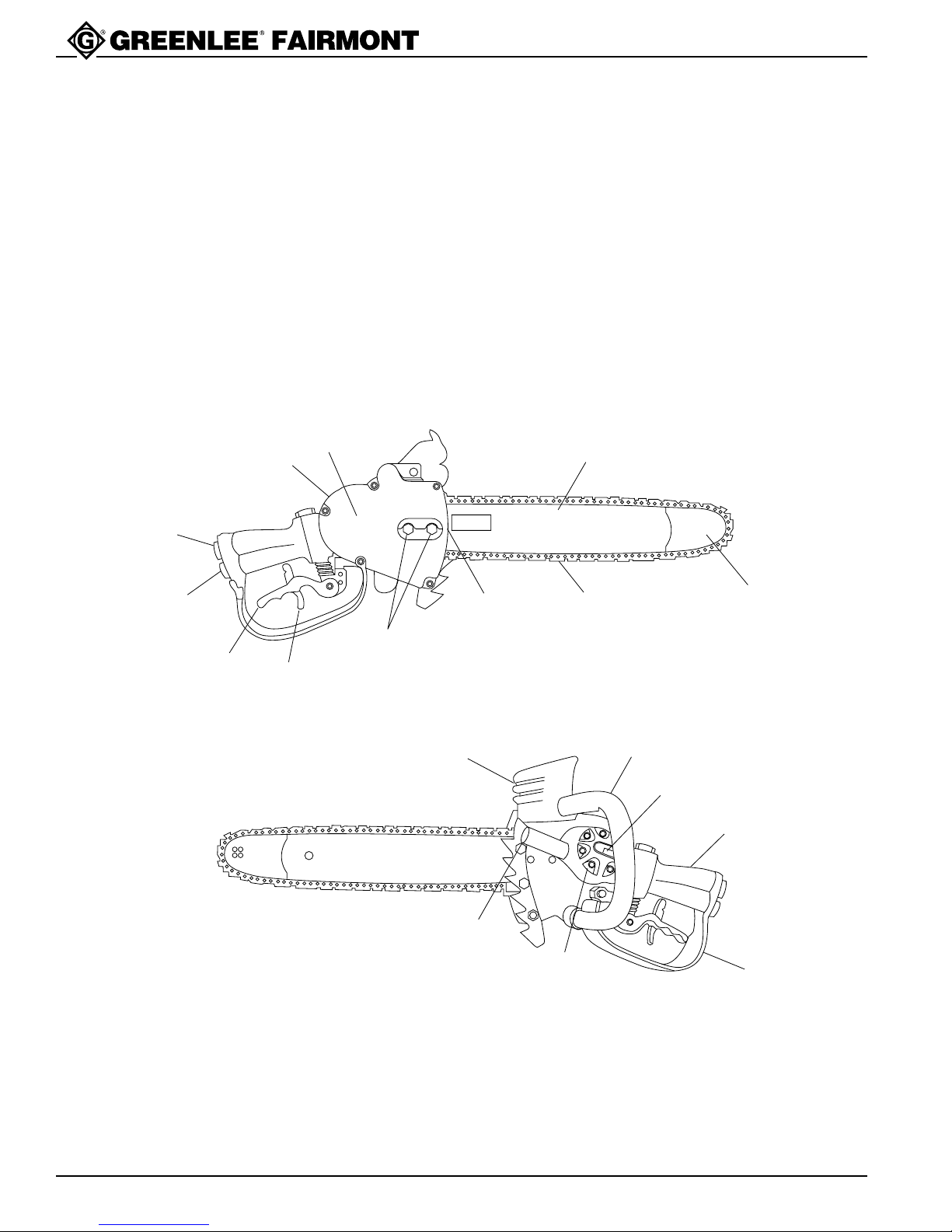

H6200B / 42247 Chain Saw

Greenlee Textron / Subsidiary of Textron Inc. 4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

Safety Information

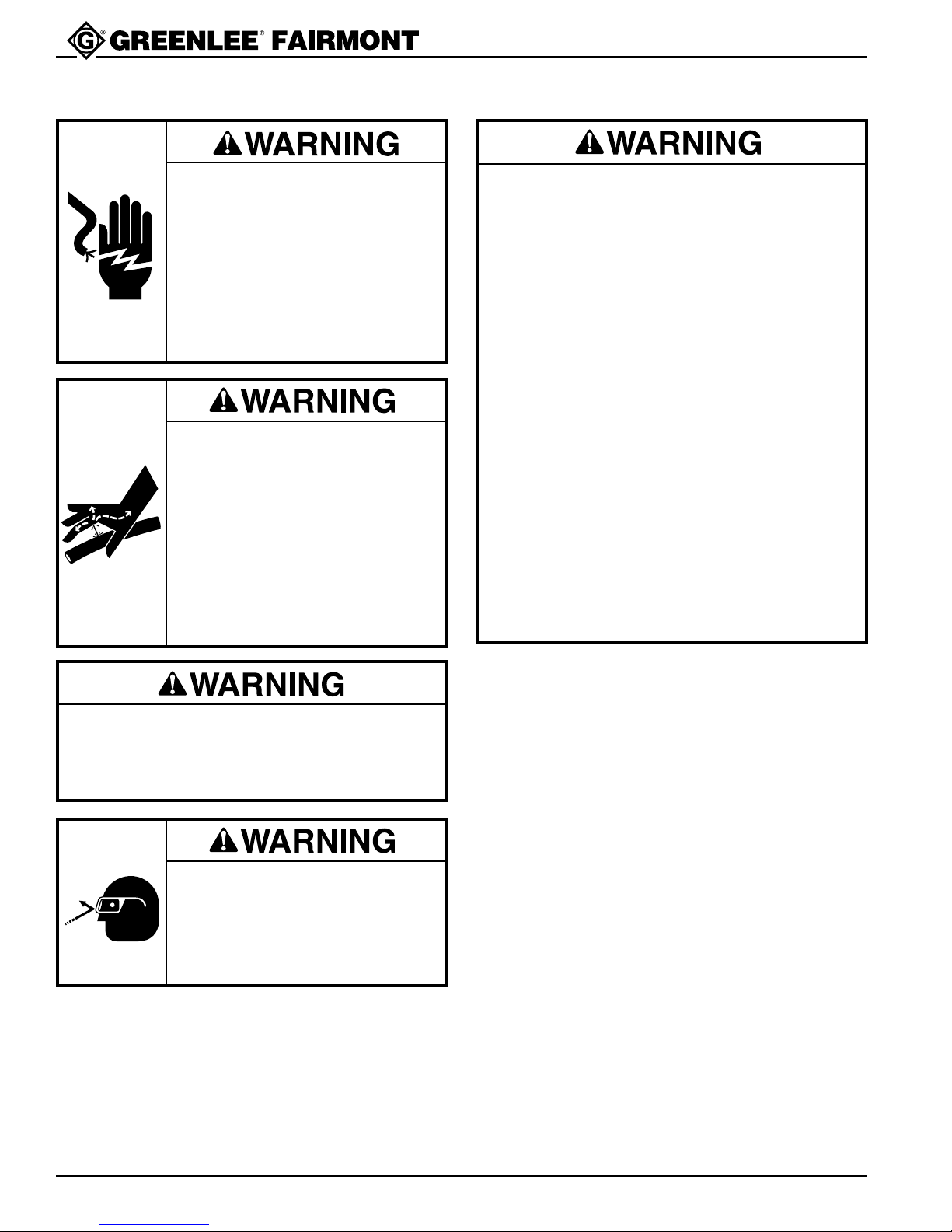

Electrical Shock Hazard:

This tool is not insulated. When

using this unit near energized

electrical lines, use only certified

non-conductive hoses and proper

personal protective equipment.

Failure to observe this warning

could result in severe injury or

death.

Skin Injection Hazard:

High pressure oil easily punctures

skin causing serious injury,

gangrene or death. If injured seek

medical help immediately to remove

oil.

Do not use fingers or hands to

check for leaks.

Depressurize hydraulic system

before servicing.

Do not disconnect tool, hoses or fittings while the

power unit is running or if the hydraulic fluid is hot.

Exposure to hot hydraulic fluid can cause serious

burns.

Wear eye protection when using

this tool.

Failure to wear eye protection can

result in serious eye injury from

flying debris or hydraulic oil.

• Do not change accessories, inspect, adjust or

clean tool when it is connected to a power

source. Accidental start-up can result in

serious injury.

• Maintain a firm grip on tool, using both hands

at all times. Serious injury can result if an

operator does not control the tool.

• Do not lock trigger in the Power-ON position.

Operator cannot stop tool when trigger is

locked.

• Do not remove or modify tool’s two-step safety

trigger. Accidental start-up can result in serious

injury.

• Always disconnect tool from power source

before attempting to adjust or service the chain

saw. Accidental start-up can result in serious

injury.

• Always wear protective gloves when handling

or adjusting the saw chain. The saw chain can

cut even when stationary.

Failure to observe these warnings could result in

severe injury or death.

• Kickback hazard:

Kickback may occur when the moving saw chain

at the nose or tip of the guide bar touches an

object, or when the wood closes in and pinches

the saw chain in the cut. Tip contact in some

cases may cause a lightning-fast reverse

reaction, kicking the guide bar up and back

towards the operator.

• Pushback hazard:

Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly back

towards the operator.

• Do not operate tool with a damaged or worn saw

chain. An improperly sharpened, dull, worn or

damaged saw chain increases the risk of

kickback and pushback.

Failure to observe these warnings could result in

severe injury or death.