Chain Saws

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

2

Safety

Safety is essential in the use and maintenance of

Fairmont tools and equipment. This instruction manual

and any decals on the tool provide information for

avoiding hazards and unsafe practices related to the

use of this tool. Observe all of the safety information

provided.

This manual introduces some general tree-trimming

and felling guidelines. For more information on these

procedures, contact:

National Arborist Association

P.O. Box 1094

Amherst, NH 03031-1094

Phone: (603) 673-8952

Fax: (603) 672-2613

Website: www.natlarb.com

Purpose of this Manual

This instruction manual is intended to familiarize all

personnel with the safe operation and maintenance

procedures for the following products:

HCS513 (49600) Chain Saw

HPS513 (49565) Chain Saw

HCS516 (49601) Chain Saw

HCS520 (49602) Chain Saw

HCS816 (49566) Chain Saw

HCS820 (49603) Chain Saw

HCS824 (49604) Chain Saw

Keep this manual available to all personnel.

Replacement manuals are available upon request at

no charge at www.greenlee.com.

Other Publications

Tool Owners / Users

Specications and Parts: Publication 99931842

Fairmont Authorized Service Centers

Repair Manual: Publication 99931850

•

•

•

•

•

•

•

All specications are nominal and may change as design

improvements occur. Greenlee Textron Inc. shall not be liable for

damages resulting from misapplication or misuse of its products.

Super Spool™ is a trademark of Greenlee Textron.

Loctite®and 242®are registered trademarks of Loctite Corporation.

KEEP THIS MANUAL

Table of Contents

Description .................................................................... 2

Safety ............................................................................ 2

Purpose ......................................................................... 2

Other Publications......................................................... 2

Important Safety Information .....................................3–5

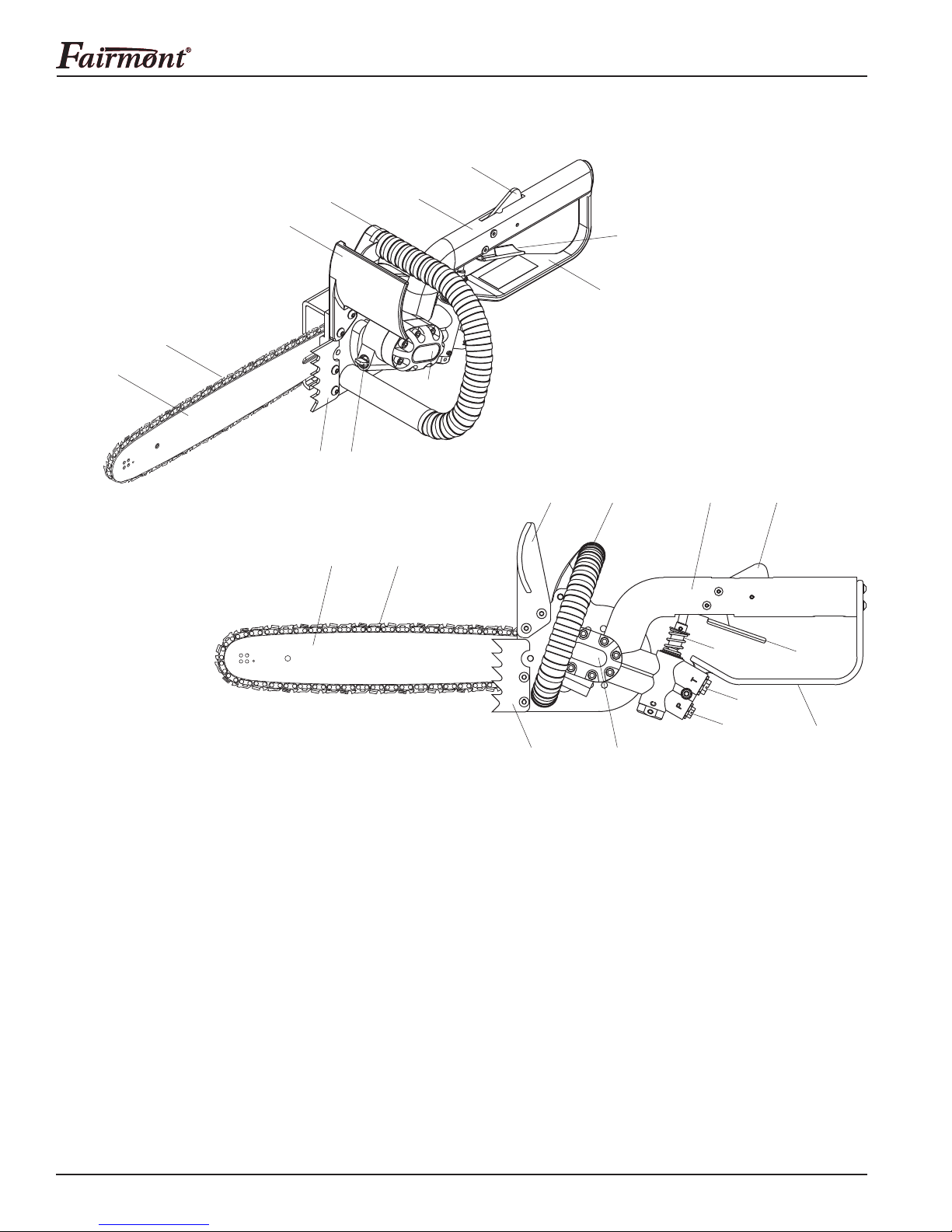

Identication.................................................................. 6

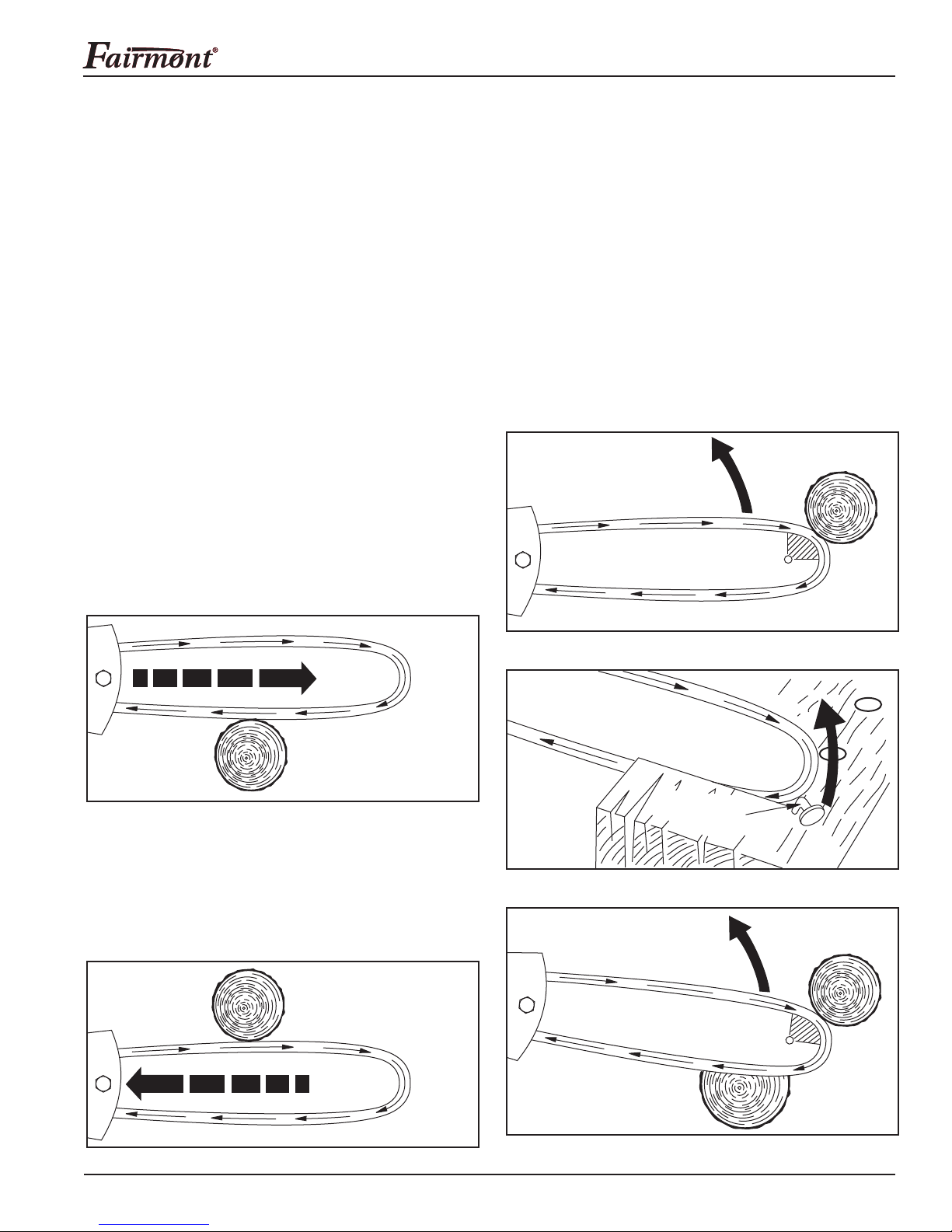

Chain Saw Basics:

Hazard Prevention ..................................................7–9

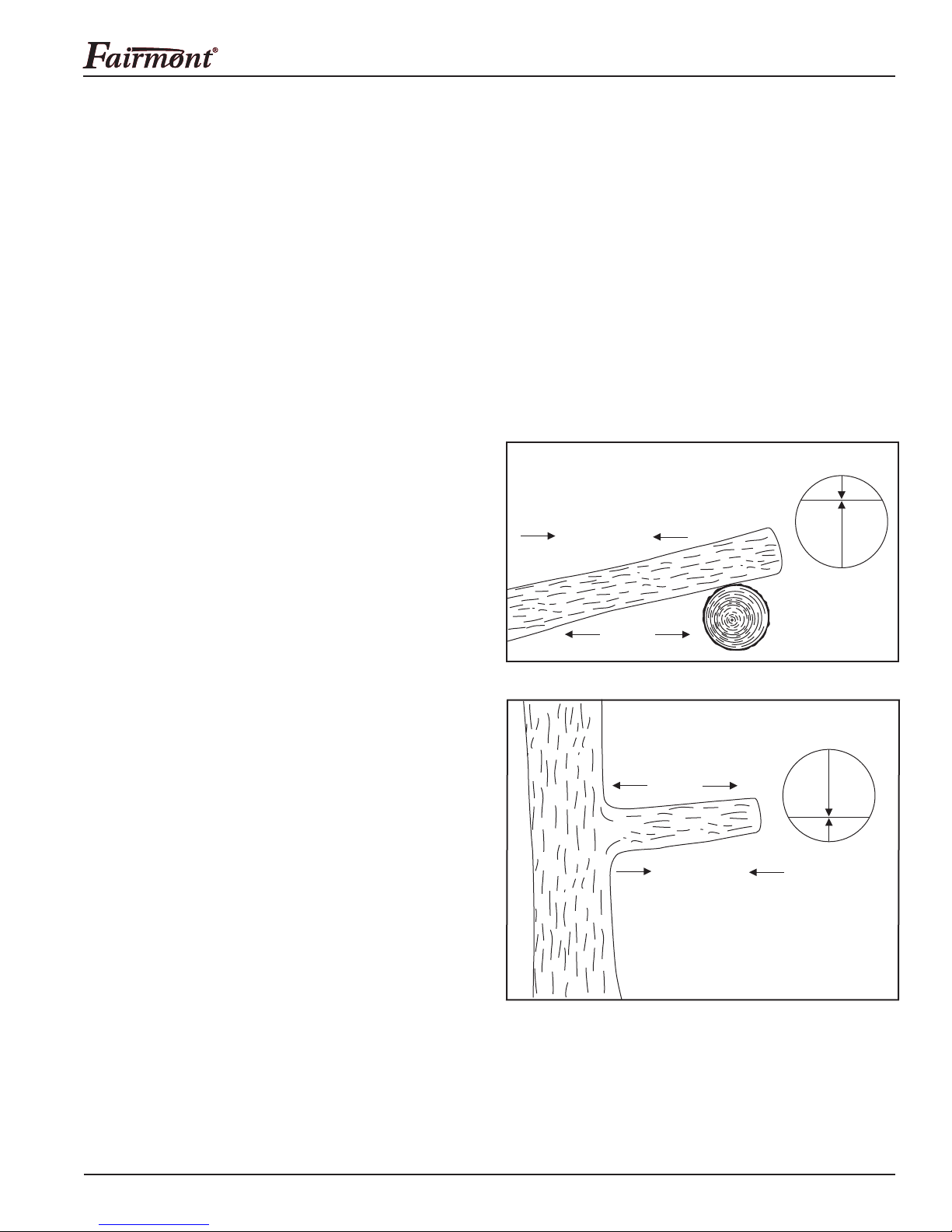

Compression and Tension ......................................... 9

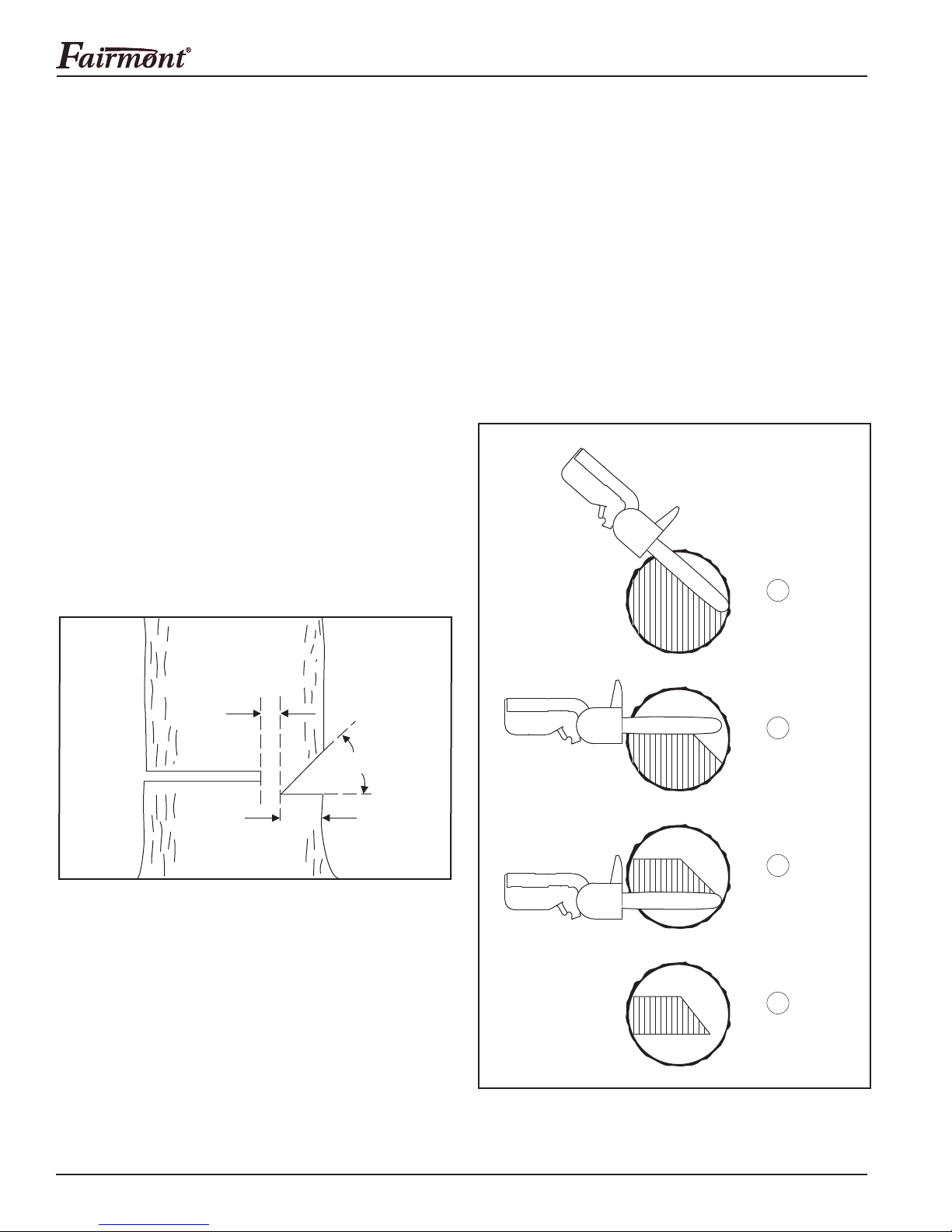

Cutting Techniques .................................................. 10

Handle Adjustment...................................................... 11

Setting the Super Spool™........................................... 12

Hoses and Fittings ...................................................... 12

Hose Connections....................................................... 12

Typical Setup............................................................... 12

Operation................................................................13–14

Maintenance:

Schedule.................................................................. 15

Checking and Setting the Automatic Chain Oiler .... 15

Saw Chain and Bar Maintenance .......................16–17

Sharpening the Saw Chain .................................18–19

Troubleshooting......................................................20–21

Description

Fairmont Chain Saws are hydraulically powered

cutting

tools intended for pruning, limbing, and felling

operations.

Powered by a rugged, direct-drive gear motor, this

type of saw provides extraordinary cutting power for

trimming and cutting from an aerial device or from the

ground.

This saw can be customized in two ways. First, the

control handle can be set to different positions —

horizontal, 30° and 60° — for the benet of the operator.

Second, the blade and bar can be replaced with a blade

and bar of a different length or pitch to adapt to various

cutting situations. For blade-and-bar combinations that

are compatible with this saw, see Accessories in the

Specications and Parts manual.

The Greenlee Fairmont Super Spool™ allows these saws

to be used on either Open-Center or Closed-Center

hydraulic systems.

Super Spool™ is protected by U. S. Patent No. 4548229.