Español(Traducción de las instrucciones originales)

10

EN DE ES

IT FR PT NL RU FI SV NO DA PL CS SK SL HR HU RO BG EL AR TR HE LT LV ET

MANTENIMIENTO Y CONSERVACIÓN

¡PELIGRO

Antes de realizar cualquier trabajo en el

aparato:

Apague la máquina. Extraiga el enchufe de red.

Espere hasta que el aparato se detenga. Asegúrese

de que el aparato y todas las herramientas

neumáticas y piezas accesorias utilizadas están

despresurizados. Deje enfriar el aparato y todas

las herramientas neumáticas y piezas accesorias

utilizadas.

Después de realizar cualquier trabajo en el

aparato:

Volver a poner en funcionamiento y comprobar todos los

dispositivos de seguridad. Asegurarse de que no haya

ninguna herramienta o similar cerca o en el aparato.

Cualquier trabajo de mantenimiento o de reparación

distinto a los descritos en este capítulo, deberá ser

realizado exclusivamente por especialistas.

Información importante

y realizarse conforme a las disposiciones legales

de acuerdo al montaje y el modo de funcionamiento

del aparato. Aufsichtsbehörden können die Vorlage

entsprechender Dokumentation verlangen.

Los organismos de inspección podrán exigir la

muestra de la documentación correspondiente.

Mantenimiento regular

Antes de cada inicio del trabajo

–Comprobar si las mangueras de aire comprimido

–

caso de ser necesario, ajústelos.

–

conexión y hacer reemplazar por un técnico

electricista.

Diariamente

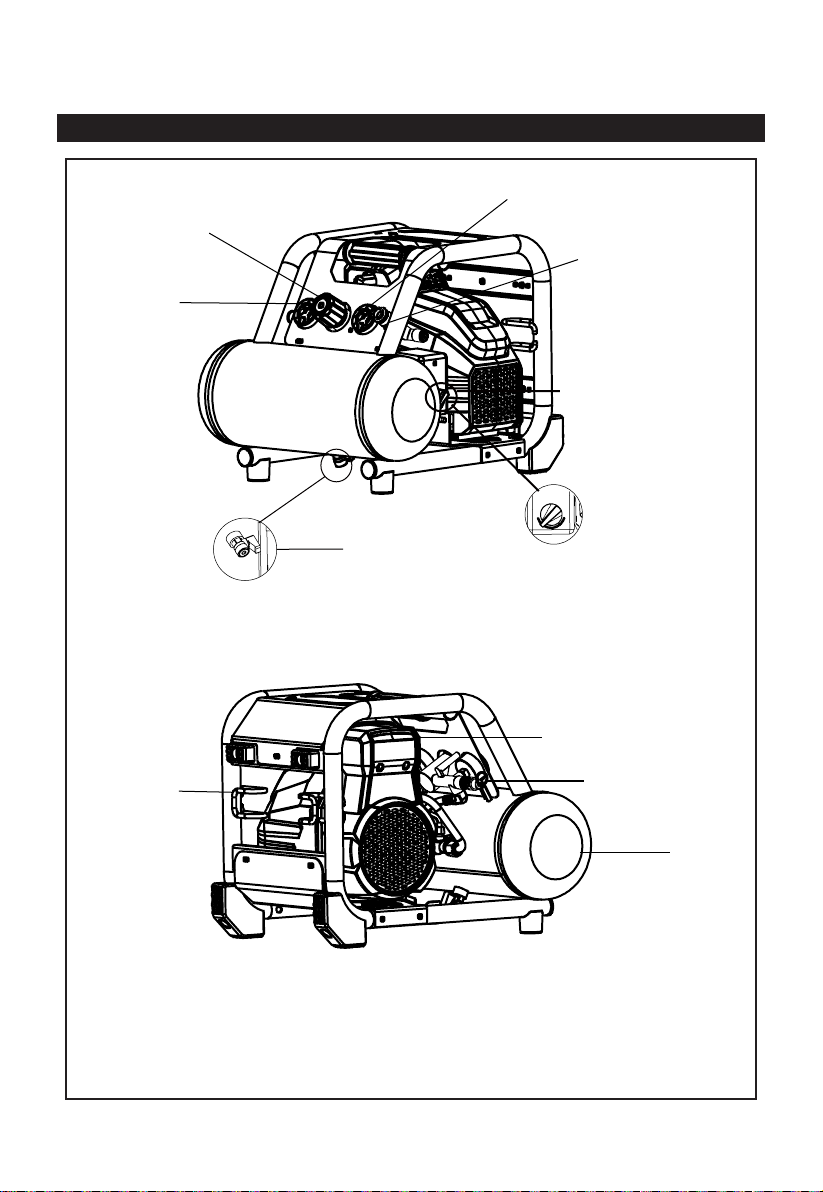

–Evacuar el agua de condensación del recipiente a

presión en la descarga de condensado (3).

Tras 1000 horas de funcionamiento

–Encargar la inspección en un taller especializado.

De este modo se eleva la vida útil del compresor de

forma sustancial.

Almacenaje del aparato

1. Desconectar el aparato y extraer el enchufe.

2. Despresurizar el recipiente de presión y todas las

herramientas neumáticas conectadas.

3. Evacuar el agua de condensación del recipiente a

presión en la descarga de condensado (3).

4. Almacenar el aparato de tal forma que no pueda ser

puesto en marcha por una persona no autorizada.

¡ATENCIÓN

No guarde nunca la máquina a la intemperie sin

protección ni en un ambiente húmedo.

En caso haber peligro de heladas

¡ATENCIÓN

Una helada (< 5 °C) destruye el aparato y el accesorio

debido a que estos siempre contienen agua. Si hay

peligro de helada, desmonte el aparato y los accesorios

y guárdelos en un lugar protegido del hielo.

REPARACIÓN

¡PELIGRO

Sólo electricistas especializados pueden realizar

reparaciones en estos aparatos.

En caso de tener un aparato eléctrico de Greenworks que

necesite ser reparado, sírvase dirigirse a su representante

de Greenworks.

PROTECCIÓN MEDIOAMBIENTAL

¡PELIGRO

El agua de condensación del recipiente a presión

contiene restos de aceite y/o impurezas contaminantes.

Elimine el agua de condensación de forma ecológica a

través de los centros de recogida correspondientes.

¡PELIGRO

Cumpla lo estipulado por las normativas nacionales

relativas a la gestión ecológica de los residuos y al

reciclaje de herramientas, embalaje y accesorios

usados.

Recicle las materias primas en lugar de tirarlas a la

basura doméstica. Para proteger el medio ambiente,

debe separar la herramienta, los accesorios y los

embalajes.