8

GENERAL SAFETY RULES

WHAT CAN HAPPEN

WHAT CAN HAPPEN

RISK OF FALLING

RISK FROM NOISE

GLOSSARY

ACCESSORIES

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

HOW TO PREVENT IT

HOW TO PREVENT IT

1

1

1

1

A portable compressor can fall

from a table, workbench, or roof

causing damage to the compressor

and could result in serious

injury or death to the operator.

Cut-In Pressure: While the motor

is off, air tank pressure drops as you

continue to use your accessory. When

the tank pressure drops to a certain

low level the motor will restart automatically.

The low pressure at which

the motor automatically restarts is

called "cut-in" pressure.

Cut-Out Pressure: When an air

compressor

is turned on and begins to

run, air pressure in the air tank begins

to build. It builds to a certain high

pressure before the motor automatically

shuts off, protecting your air tank

from pressure higher than its capacity.

The high pressure at which the motor

shuts off is called "cut-out" pressure.

Branch Circuit: Circuit carrying electricity

from electrical panel to outlet.

Become familiar with these terms

before operating the unit.

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute;

a unit of measure of air delivery.

PSI: Pounds per square inch gauge;

a unit of measure pressure.

Code Certication: Products that

bear one or more of the following

marks: UL®*, CUL, ETL®*, CETL, have

been evaluated by OSHA certied

independent safety laboratories and

meet the applicable Standards for

Safety.

*UL® is a registered trademark of

Underwriters Laboratories and ETL®

is a registered trademark of Electrical

Testing Laboratories.

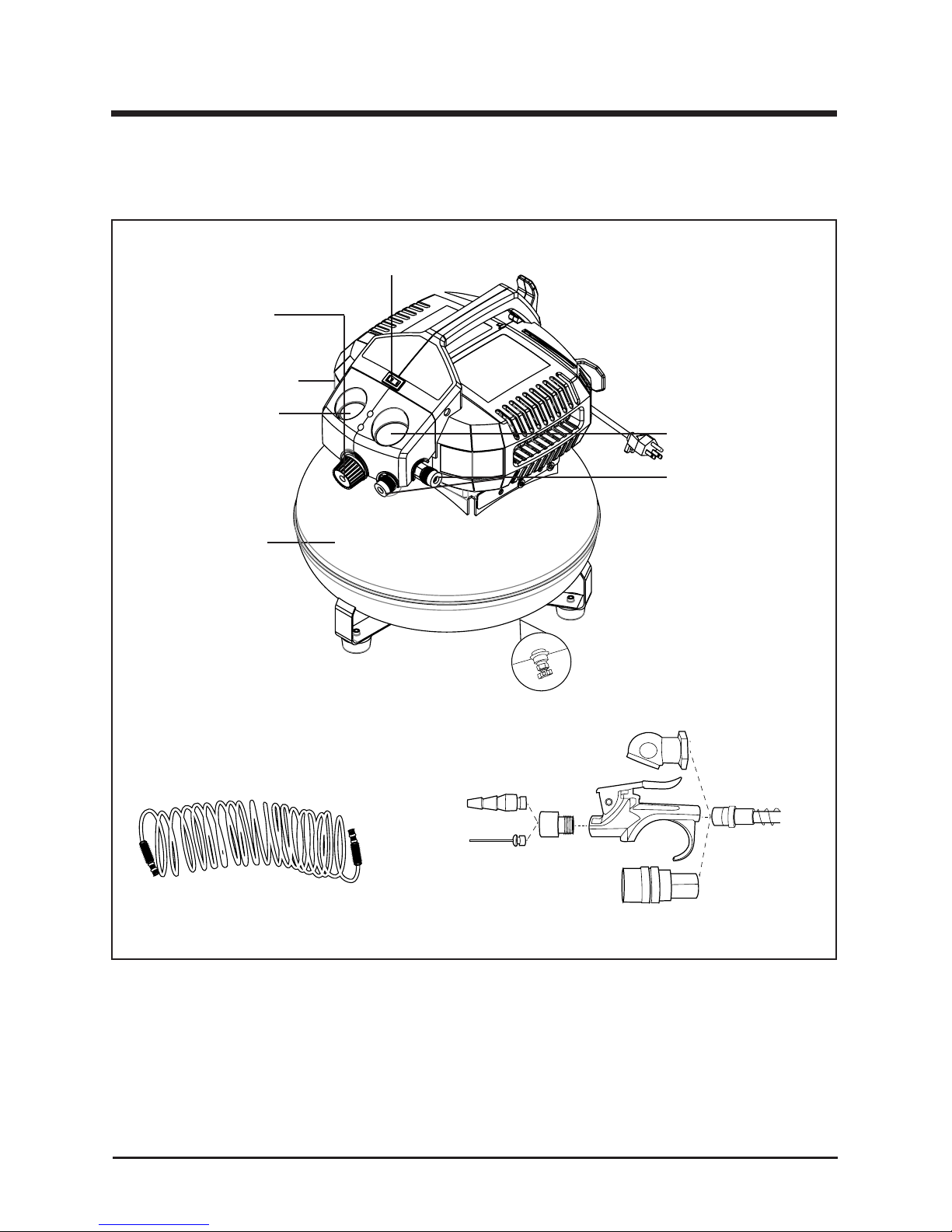

Includes: Recoil Hose, Blow gun, 1/4" Quick connector, Tire chuck, Ination needle

Blow gun adaptor, Tapered nozzle, Plumber's tape

Under some conditions and

duration of use, noise from this

product may contribute to hearing

loss.

Always operate commpressor in a

stable secure position to prevent

accidental movement of the unit.

Never operate compressor on a

roof or other elevated position.

Use additional air hose to reach

high locations.

Always wear certied safety

equipment: ANSI S12.6 (S3.19)

hearing protection.