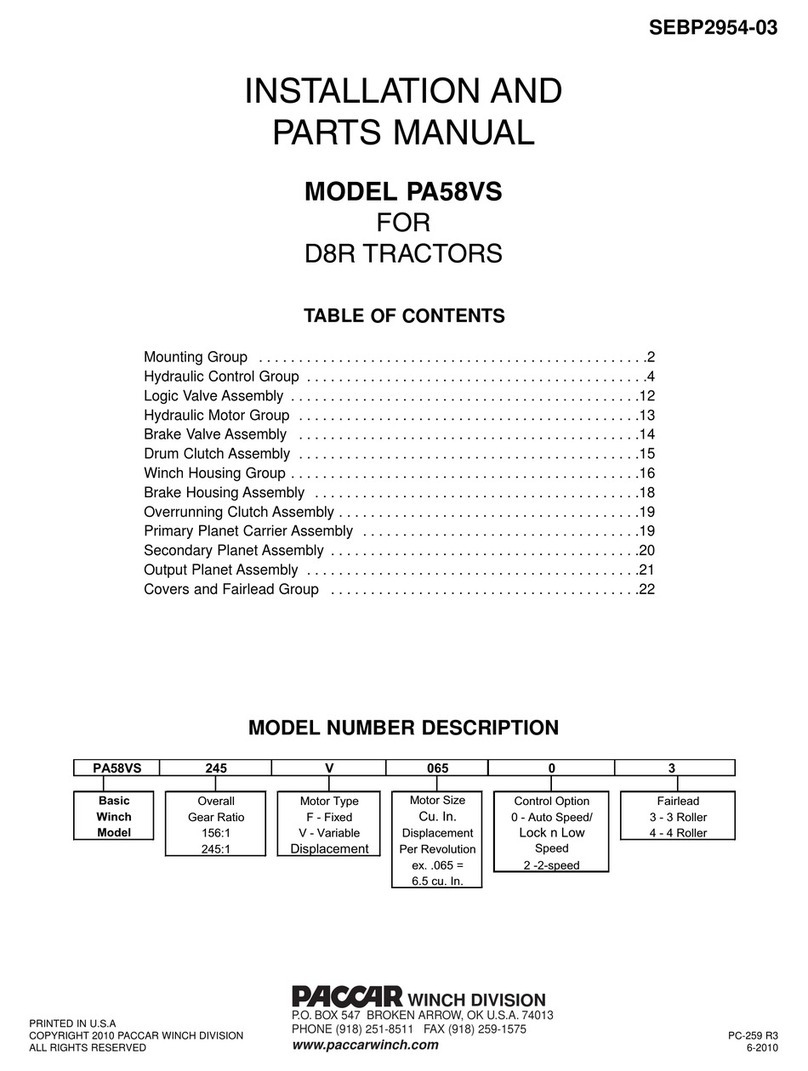

5

10. The factory approved adaptions for PACCAR winches

are designed and intended for use on specific models

of crawler tractors. Changing winches between trac-

tors is not possible in some cases because of differ-

ences in tractor models. Some changes cannot be

approved by PACCAR because of safety limitations.

Call the tractor dealer or the PACCAR factory prior to

attempting winch modifications or before mounting on

a different tractor.

11. PACCAR H50 winches are powered by the tractor hy-

draulic system. Turn off engine and discharge all re-

tained hydraulic system pressure before removing any

hydraulic lines or fittings. Personal injury may result

from sudden release of oil pressure.

12. On machines having hydraulically, mechanically and/

or cable controlled equipment, be certain the equip-

ment is either lowered to the ground or blocked se-

curely before servicing, adjusting and/or repairing the

winch. Always apply tractor parking brakes and lower

equipment before dismounting the tractor.

13. The winches described in this manual are neither de-

signed nor intended for use or application to equipment

used in the lifting or moving of persons.

14. Install guarding to prevent personnel from getting any

part of their body or clothing caught at a point where

the cable is wrapped onto the drum or drawn through

fairlead guide rollers.

15. Keep equipment in good operating condition. Perform

scheduled servicing and adjustments listed in the “Pre-

ventive Maintenance” section of this manual. Use rec-

ommended lubricants.

16. An equipment warm-up procedure is recommended

for all start-ups and essential at ambient temperatures

below +40°F (5°C). Refer to “Warm-Up Procedure”

listed in the “Preventive Maintenance” section of this

manual.

17. Don’t weld on any part of the winch without PACCAR

Winch Division approval.

WINCH DESCRIPTION

ThePACCAR H50 winchis ahydraulically drivenwinch uti-

lizing a dedicated piston pump for power input. The winch

hydraulic oil pump is usually installed on the tractor trans-

mission pump and the tractor implement pump is installed

on the winch pump in a piggy-back arrangement when

the winch is installed on the tractor. The winch includes

both planetary and standard spur gears as well as a spring

applied, hydraulically released multi-disc static brake for

holding the load secure while in the neutral “Brake-On”

position. The winch case is designed to bolt to the rear

face of the tractor.

When operated in either the Reel-In or Reel-Out direction,

the variable displacement, piston hydraulic motor drives

the gear train. Winch line speed and load control are pro-

portionate to the amount of oil being delivered to the winch

motor by the hydrostatic control system. The winch brake

must be released by pilot pressure through the winch con-

trol valve in both Reel-In and Reel-Out directions.

The Freespool mechanism is a spring-engaged, hydrau-

lically released, splined gear-type connection. As the

control lever is moved into the Freespool position, the oil

is ported through the winch logic valve assembly to re-

lease the brake, and into the freespool cylinder to force

the freespool piston against the coil spring and disengage

the splined connection. This allows the winch cable to be

pulled off the cable drum by hand.

“Drive-Away” mode is controlled by the winch motor. This

function allows the operator to drive the tractor away from

the load while back driving the motor with the winch gear

train. When the control lever is moved into the Drive-Away

position, the winch motor / cartridge valve assembly lim-

its the flow of the hydraulic oil through the motor and the

winch brake to allow for smooth, controlled pay-out of the

winchcable.The maximum back drivenspeed of the winch

motor is limited by a flow control valve set to achieve ap-

proximately 2.6 mph (4.2 km/h) tractor ground speed at

the winch bare drum condition.

An optional three roller or four roller fairlead assembly is

available for applications in which slight side directional

pulls are routinely encountered. Use of a fairlead assem-

bly will help to maximize winch case and wire rope life by

eliminating wear due to contact in these applications.