12

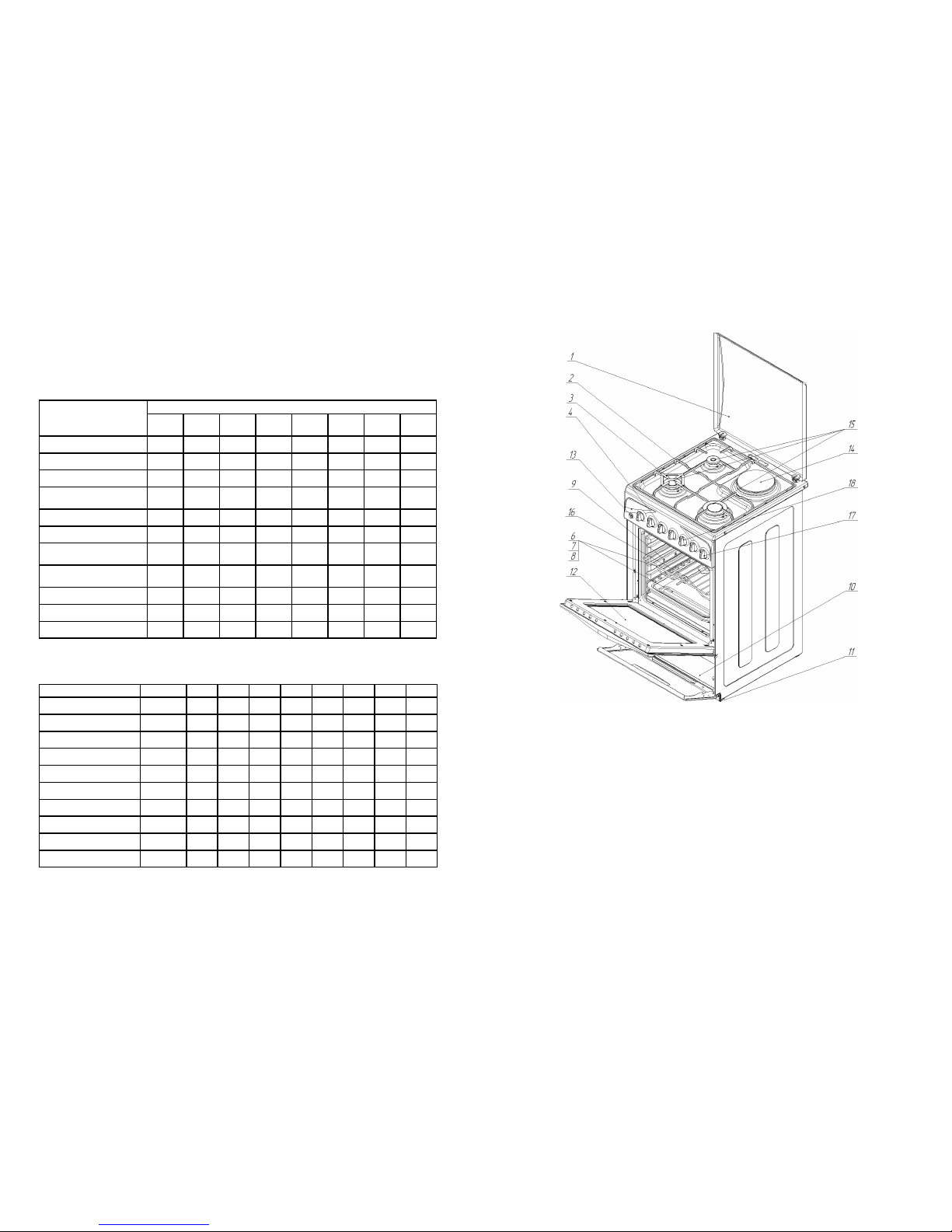

The cooker consist out of working table – table with the burners, electrical oven and

domestic chamber (pic.5).

Working table of the cooker has 4 gas burners pos. 115 or 3 gas burners and one

electrical plate pos.

Control of the cooker is made by means of handles pos. 4, 17, 18 which are located

at control board.

There is a grid pos. 2 at the table of the cooker surving for tablewares putting.

Electrical oven has two heating elements, one of which is installed in the upper part,

another in the lower part.

Electric oven has highlight device (except execution 06).

Control lamp of thermoregulator of electric oven is switching off in achievement of

fixed temperature in the oven.

In lower part of the gas electric cooker domestic chamber pos.10 is situated, which is

intended for tableware keeping.

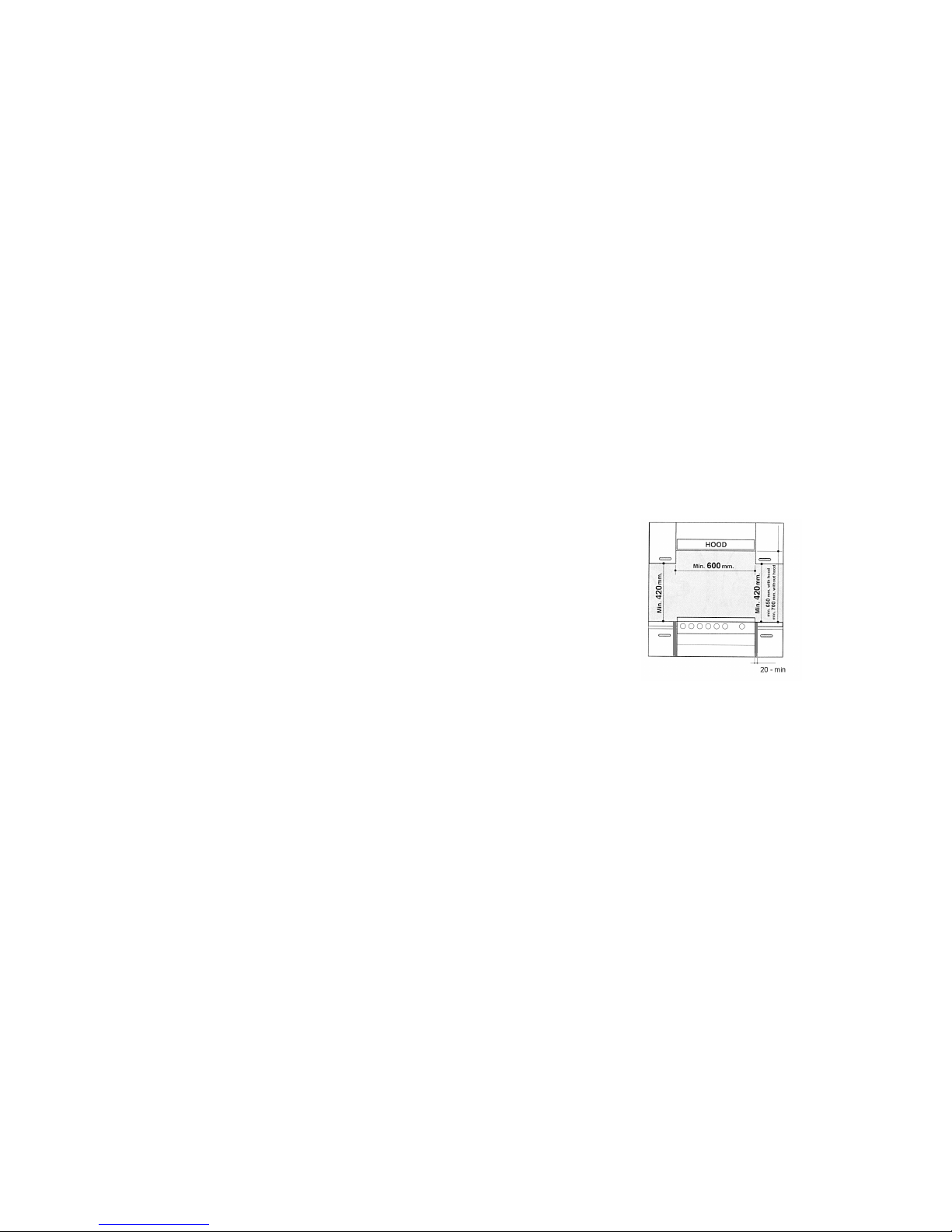

Pic. 6

The cooker stands at four easy regual-

ated legs pos.11.

Cooker can be equipped with the Grill

heating element (with the power 1,5kW)

with electrical turnspit (pic.6). Before ap-

plication it is necessary to set turnspit at

the motor sleeve and at the support, see

Pic.6.

During cooking the handle of the turn-

spit must be removed and door closed.

The cooker can have mechanical timer

for sound signal supply. Range of set time

is 1….60 min. Timer switching on is made

by appropriate handle (pos. 8 pic.8) at the

control board by clockwise turn.

OPERATING SEQUENCE

Turn on of as burners with the system of as control.

To push and turn counter-clockwise the handle, according to the burner in use , to put

it in the position «maximum flame» and bring alight the match or to turn on the push but-

ton of ignition , for the cookers with ignition. The handle of the gas valve take on

in the pressed condition not less then 10 seconds, just for the device had a time to snap

into action.

Attention! If the burner was not li hted, it is necessary to switch it off and re-

peat i nition not less than in 1 minute.

• Adjustment of intensity of burning is made by the further turn of the handle of the

valve counter-clockwise - thus should not occur casual extinction of the burner. At turn

against the stop the burner will work on minimal flame .

• to switch off the burner, it is necessary to turn the valve handle clockwise against

the stop.

9

• Do not allow the children or the people which are not acquainted with the present

operation manual, to use the cooker during your absence.

• When operating of the grill or of the oven come-at-able details of the oven can be

hot very much. Do not allow to the children to approach to the oven. To avoid oven door

overheatin it is recommended to set the temperature of heatin element rill

thermore ulator not more then 2000C

• This device is not destined for use by people (including children) with limited physi-

cal, sensible and mental abilities or absence of experience and knowledge and people

didn’t receive corresponding indications, advices and control about use of the device by

man, who is responsible for safety.

• Children need care to guarantee their not playing with device

• During use of the device surface became hot. Measures excluding touch to heating

elements inside the oven must be taken

• Attention: open parts can become hot during use. Little children must be aside.

• The change of the cooker design and intervention of the people not authorized by

the Manufacturer on guarantee repair are forbidden.

• When using the small kitchen electro devices near the cooker, watch, that their feed-

ing cables do not touch hot parts of the equipment.

• Disconnect the cooker from network when you leave for a long time. Block gas sup-

ply.

• Do not use inflammable liquids (alcohol, petrol, etc.) near the running equipment.

• Do not put on the cooker dishes with the rough or deformed bottom. Try to have the

dishes in such a way, that handles do not overheat, and that it was impossible to overturn

ware, casually having touched the handles.

• If the cooker is not used, check up, that control handles on the board are in posi-

tion - closed.

• Never allow the children to be near the cooker when you use the oven.

• The parts of the cooker (especially electric heater) after switching off remain hot

for a long time. Be careful, do not touch the cooker, wait, till it will cool down completely.

• It is forbidden to clean the oven by means of steam.

• The Prevention:

Never put the hot ware and flammable materials in the domestic chamber.

Never leave the running gas burners empty or with not used ware as the ware quickly

heats up and can damage the equipment.

ome models of the cookers are equipped with glass cap. In avoidance of glass crack-

ing it is forbidden the following:

- to light table burners at closed cap

- to lower the cap when hobs are running or still are hot.

• Clean the lid from different items before open

• Table heating elements must get cold before close a lid.

• The usage of the gas cooker demands a constant air flow. When installing the cook-

er, strictly follow the instructions mentioned in the paragraph «The Instruction on installa-

tion» of the present manual.

• At occurrence of a non-standard situation disconnect the cooker from network, and

apply to gas service on your residence.

• If you have decided, that the cooker does not suit for exploitation, make it unsuitable

for use: disconnect from the network, cut off feeding cable, remove potentially danger-

ous parts (it is especially important for safety of children which can play with not used or

thrown devices).

Attention! For maintenance of effective and safe work of the equipment we urgently

recommend:

do not use the help of the not authorized by the manufacturer people, to demand to

use the original spare parts at repairs.