Beijing Grinder Instrument Co., Ltd. Tel:010-82363430 Fax:010-82363435 www.grindertech.cn

CONTENT

1.0 Notes on the Manual................................................................................................................. 3

2.0 Safety...........................................................................................................................................3

2.1 General instructions.......................................................................................................... 3

2.2 Warning............................................................................................................................... 3

2.3 Repair.................................................................................................................................. 4

2.4 Safety instructions............................................................................................................. 4

Please use it normally.........................................................................................................4

3.0 Packing and transportation...................................................................................................... 5

3.1 Packing................................................................................................................................5

3.2 Transportation................................................................................................................. 5

3.3 Storage................................................................................................................................ 5

3.4 Supply list............................................................................................................................5

3.5 Ambient temperature......................................................................................................6

3.6 Air humidity......................................................................................................................... 6

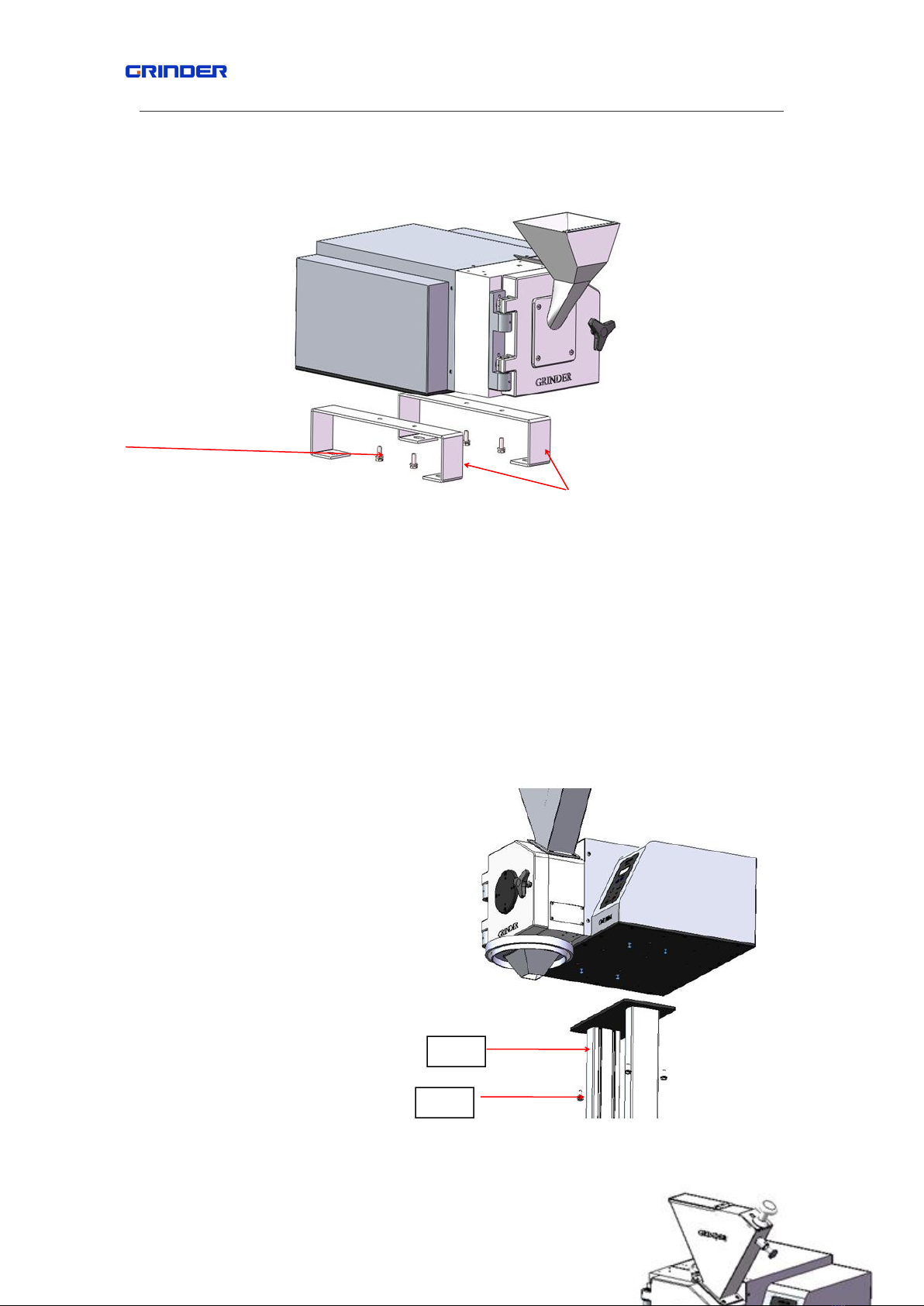

3.7 Base frame installation (fig3.7.1~3.7.4)...................................................................... 6

3.8 Installation main body (Fig 3.8.1~3.8.4)................................................................ 7

3.9 Power connection (fig 3.9)....................................................................................... 9

4.0 Technical specifications............................................................................................................ 9

4.1 Introduction of function characters................................................................................. 9

4.2 Electrical parameters...................................................................................................... 12

4.3 Feed size.......................................................................................................................... 12

4.4 Collecting bucket............................................................................................................. 13

4.5 Instrument size.................................................................................................................13

4.6 Weight............................................................................................................................... 13

4.7Floor space........................................................................................................................ 13

5.0 Installation.................................................................................................................................13

5.1 Instrument units(fig 5.1.1~fig 5.1.5)........................................................................ 13

5.2 Spare parts function list..................................................................................................15

5.3 Open/close grinding room door (fig 5.3.1~5.3.2).................................................17

5.4 Install/replace the cutting type accessories(fig 5.4.1~5.4.4).............................. 18

5.5 Install/replace the cross beater type accessories......................................................19

5.6 Install/replace the rotor beater type accessories....................................................... 21

5.7 Collecting bucket installation (fig 5.7).................................................................... 23

5.8 Control panel(fig 5.8)...........................................................................................23

5.9 Control panel function list...............................................................................................23

5.10 Feed sample materials.................................................................................................24

5.11 Preparation before grinding......................................................................................... 24

5.12 Universal hopper (fig 5.12)..................................................................................25

5.13 Standard hopper (Fig 5.13)................................................................................... 25

5.14 Start instrument............................................................................................................. 26

5.15 Stop the instrument.......................................................................................................26

5.16 Using the cyclone..........................................................................................................26