54

SAFETY

SAFETY

SAFETY INSTRUCTIONS

WEAR SAFETY GLASSES

Always wear safety glasses with side shields that meet ANSI

Z87.1 requirements when operating the tool. Make sure all

others in work area wear safety glasses.

WEAR HEARING PROTECTION

Wear hearing protection to protect your hearing from noise.

Prolonged exposure to loud noise can result in hearing loss.

NEVER OPERATE THE TOOL WITH OXYGEN OR OTHER

BOTTLED GASES

Oxygen and other reactive or high-pressure bottled gases

can cause the tool to explode. Use clean, dry regulated

compressed air from a properly operating air compressor.

DO NOT EXCEED MAXIMUM RECOMMENDED OPERATING AIR

PRESSURE OF 110 PSI /7.6 Bar.

Exceeding the maximum recommended air pressure can

cause the tool housing to burst, or cause premature failure of

components.

NEVER CONNECT THE TOOL TO AN AIR SUPPLY THAT HAS

THE POTENTIAL TO EXCEED 180 PSI/12.4 Bar.

Using a regulated air supply with a line or tank pressure

greater than 180 psi can cause the tool to burst if the air line

regulator fails suddenly.

USE AN AIR HOSE RATED FOR 180 PSI/12.4 Bar OR

GREATER

Always use air hose rated to handle 180 psi or the maximum

potential pressure of the air supply.

DO NOT ATTEMPT TO OPERATE THE TOOL IF THE TOOL’S

OPERATING CONTROLS HAVE BEEN MODIFIED ORARE NOT

WORKING PROPERLY.

Attempting to use a tool with modified or malfunctioning

trigger or workpiece contact can result in a fastener being

driven unintentionally.

USE CORRECT FASTENERS

Only use the correct fastener for the tool. Using fasteners

with incorrect specifications can jam the tool or cause

serious injuries.

110 psi

4 bar

60 psi 7.6 bar

USE THE CORRECT FASTENERS FOR THEAPPLICATION.

Using the wrong fasteners can cause the workpiece to split and allow the

fastener to fly free.

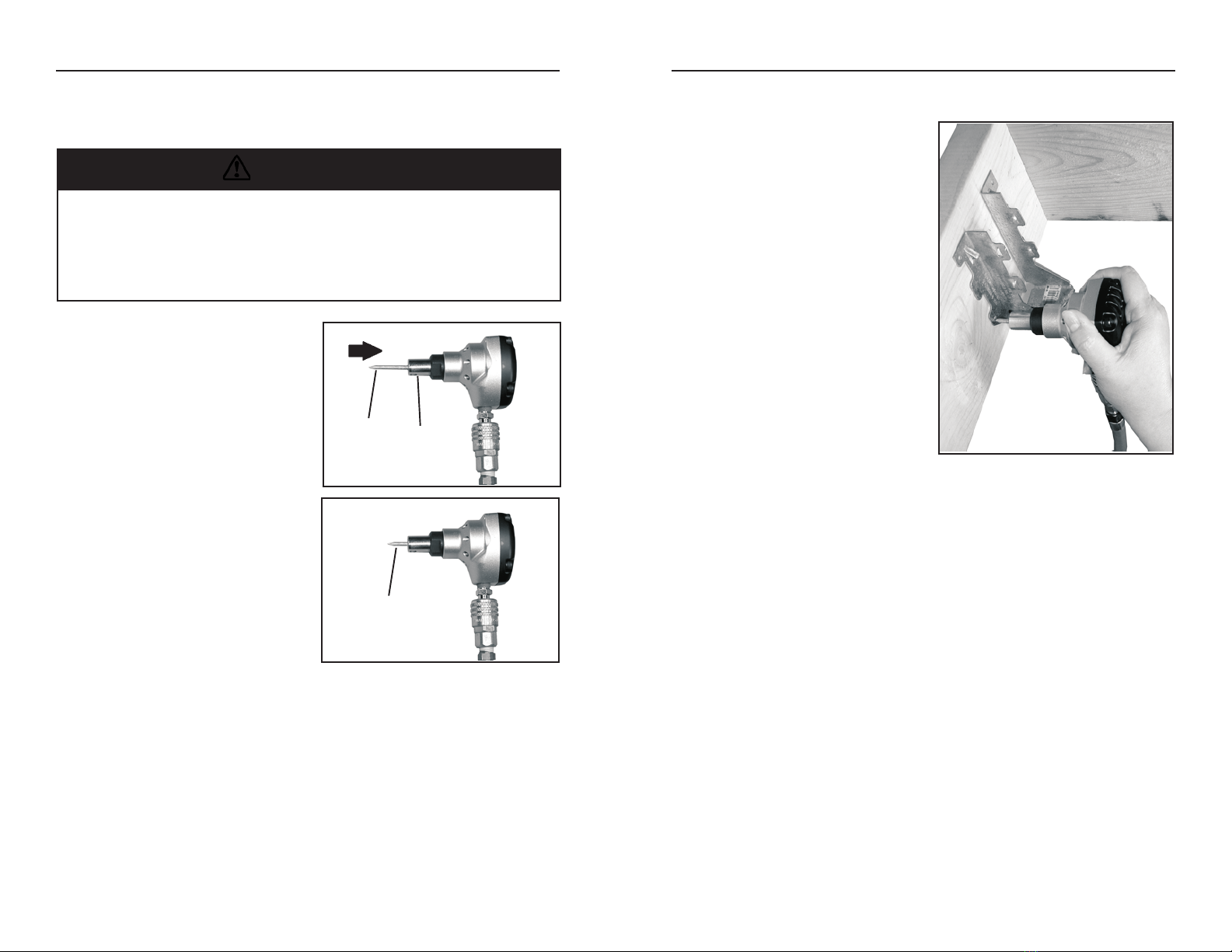

DO NOT DEPRESS TOOL NOSE WHEN LOADING FASTENERS

Depressing the tool nose during loading can result in tool actuation and an

unintentional fastener drive

AVOID DRIVING FASTENERS INTO KNOTS, ON TOP OF OTHER FASTENERS, AT

WORKPIECE EDGES, OR INTO BRITTLE MATERIALS.

Driving fasteners into extremely hard materials, or driving into workpiece

edges, can cause fasteners to deflect away from the workpiece. Flying

fasteners can cause serious injuries.

KEEP HANDSAND BODY PARTS AWAY FROMAREA BEING FASTENED.

Fasteners can deflect and turn as they are being driven into the workpiece, and

penetrate fingers, hands, and other body parts that may be in the fastening

area.

DO NOT OVERREACH OR WORK WHILE ON UNSTABLE FOOTING

If you lose your balance while fastening, you could drive a fastener into yourself

or a bystander.

DO NOT USE TOOL IF TOOL MALFUNCTIONS OR BEGINS LEAKING AIR.

Operating a malfunctioning tool can result in an injury to yourself or others.

DISCONNECT THE TOOL FROM THE AIR SUPPLY TO PERFORM MAINTE-

NANCE.

Never attempt to reload a tool, clear a jam, or perform maintenance without

first disconnecting the air supply.

NEVER LEAVE A PRESSURIZED TOOL

UNATTENDED

A pressurized tool could be picked up or handled by someone who is unfamil-

iar with the tool or that has not read the tool manual.

KEEP TOOLS OUT OF THE REACH OF CHILDREN

Place the tool back in the tool box after use, and store the tool out of reach.

DO NOT MODIFY TOOL

Modifications can cause a tool to be unsafe and can cause the tool to operate

improperly.

SAFETY INSTRUCTIONS