4ABLEOF#ONTENTS

).42/$5#4)/.

;dgZldgY#################################################################################################################################### (

8dciVXi>c[d################################################################################################################################ (

BVX]^cZ9ViVH]ZZi################################################################################################################### )

>YZci^[^XVi^dc############################################################################################################################### *

3%#4)/.3!&%49

HV[Zin>chigjXi^dch[dgBVX]^cZgn############################################################################################### +

6YY^i^dcVaHV[Zin>chigjXi^dch[dgIVWaZHVlh########################################################################### -

EgZkZci^c\@^X`WVX`################################################################################################################### .

EgdiZXi^c\NdjghZa[;gdb@^X`WVX`############################################################################################ .

<adhhVgnd[IZgbh#################################################################################################################### &%

3%#4)/.#)2#5)42%15)2%-%.43

DeZgVi^dc################################################################################################################################## &&

<gdjcY^c\################################################################################################################################# &'

:miZch^dc8dgYh####################################################################################################################### &'

3%#4)/.3%450

HZiJeHV[Zin########################################################################################################################### &(

>iZbhCZZYZY[dgHZiJe######################################################################################################### &(

JceVX`^c\################################################################################################################################ &(

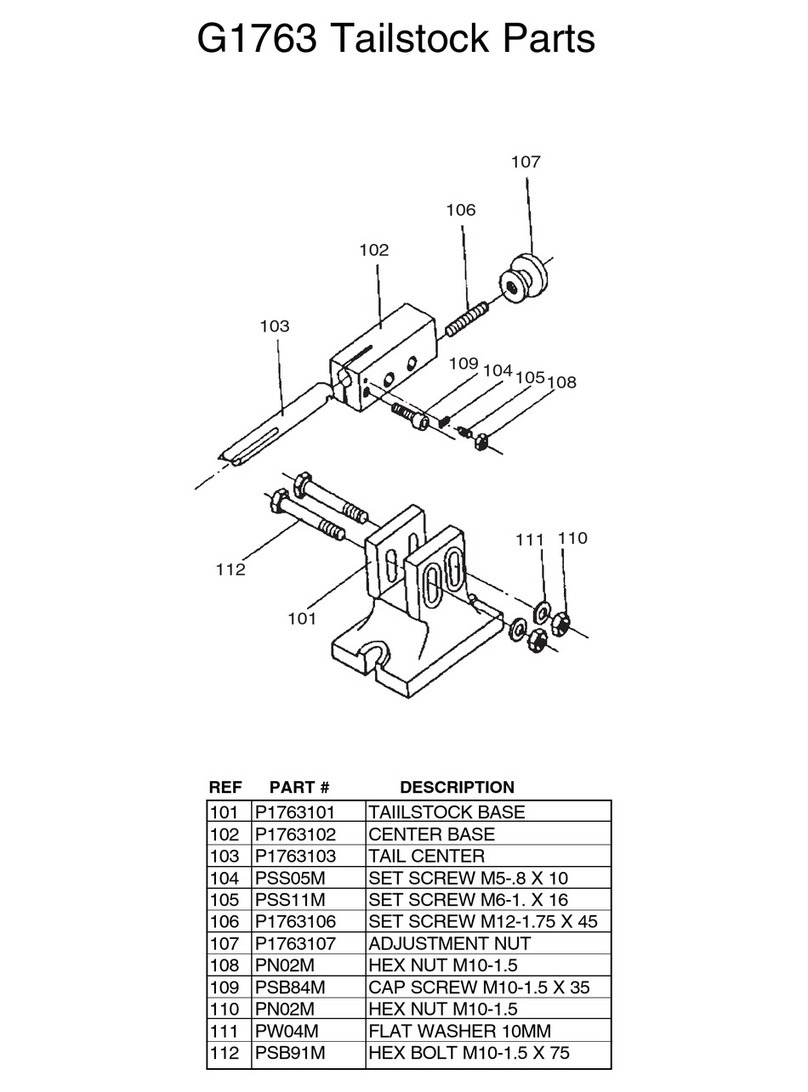

=VgYlVgZGZXd\c^i^dc8]Vgi####################################################################################################&)

BVX]^cZ>ckZcidgn#################################################################################################################### &*

;ZcXZ>ckZcidgn####################################################################################################################### &+

<&%'(HA!L!LM!LM(###########################################################################################################&+

;ZcXZ>ckZcidgn####################################################################################################################### &+

<&%'(HAM################################################################################################################################ &+

GdjiZgIVWaZ>ckZcidgn############################################################################################################# &,

8aZVcJe################################################################################################################################## &,

H^iZ8dch^YZgVi^dch################################################################################################################## &-

Bdidg7gVXZ############################################################################################################################## &-

IVWaZh####################################################################################################################################### &.

Hl^iX]####################################################################################################################################### '%

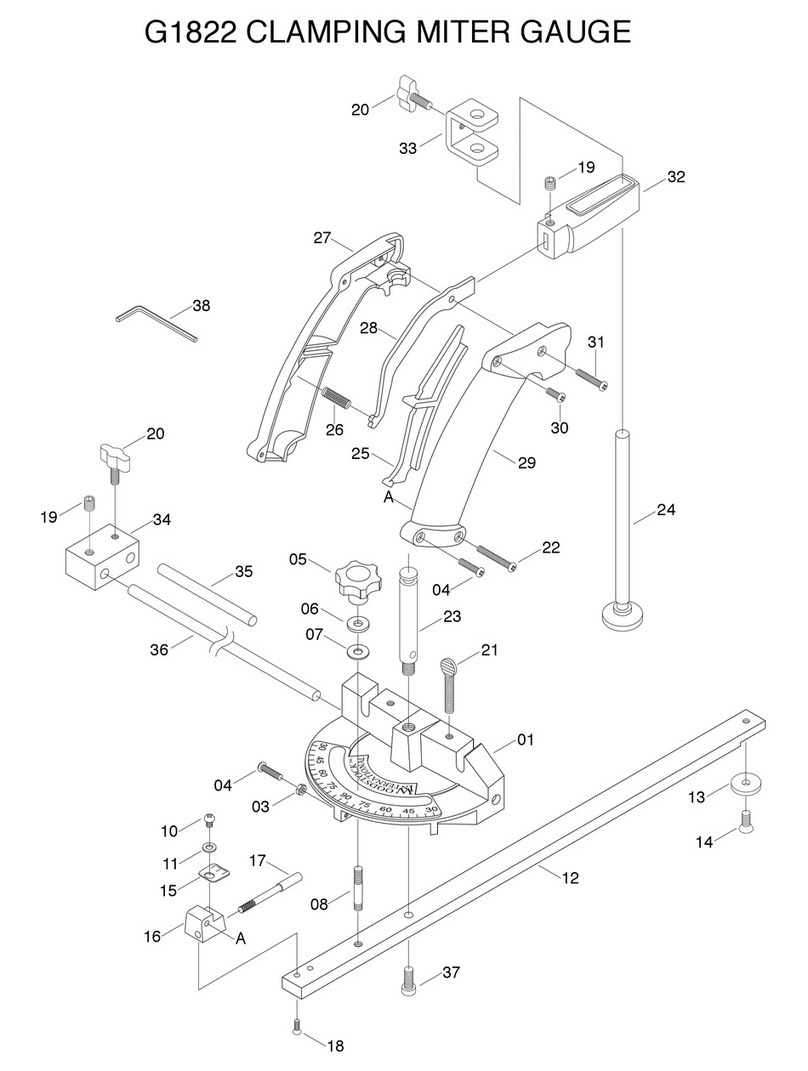

;ZcXZ####################################################################################################################################### '%

GdjiZgIVWaZAZ\h<&%'(HAL!LM!LM(########################################################################### '%

:miZch^dcIVWaZAZ\h<&%'(HAM######################################################################################## '&

Bdidg8dkZg############################################################################################################################# ''

9jhiEdgi################################################################################################################################## ''

=VcYl]ZZaAdX`@cdW=VcYaZ############################################################################################# ''

IVWaZ>chZgi############################################################################################################################## '(

HVl7aVYZ################################################################################################################################ '(

<jVgY7gVX`Zi########################################################################################################################## ')

7aVYZ<jVgY$Hea^iiZg################################################################################################################# ')

EgZ"Gjc8]ZX`######################################################################################################################### ',

IZhiGjc################################################################################################################################### ',