-4- H8368 Electric Power Drawbar

Power Connection Device

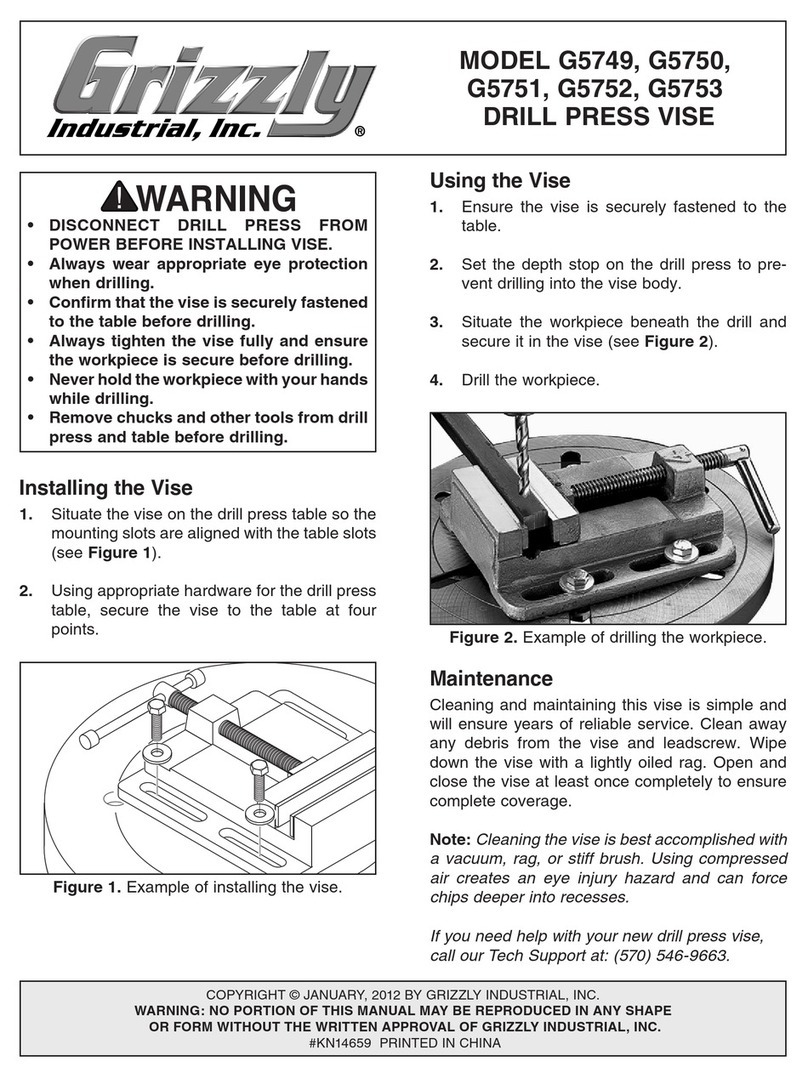

The type of plug required to connect your machine

to power depends on the type of service you cur-

rently have or plan to install. We recommend

using the plug shown in Figure 10.

Electrocution or fire could

result if machine is not

grounded and installed in

compliance with electrical

codes. Compliance MUST

be verified by a qualified

electrician!

Figure 10. NEMA 6-15 plug and receptacle.

Operation

1. Connect the drawbar unit to power.

Cutting tools are sharp! When using the

power drawbar, the tooling may spin a little.

Protect your hands when using the power

drawbar to load or unload tooling.

2. To install tooling:

a. Insert the tooling into the spindle in the

normal manner that is correct for your

mill, and up against the bottom of the

drawbar assembly.

b. Press the IN button on the drawbar

switch to activate the drawbar motor and

thread the drawbar into the tooling.

Note: When the tooling is fully secure and

you can hear the drawbar motor begin to

"ratchet", release the IN button. DO NOT

overly tighten the tooling.

3. To un-install tooling, press the OUT button of

the drawbar switch to release and unthread

the tooling.

Note: As the tooling is released from the

drawbar, it could suddenly drop out of the

spindle.

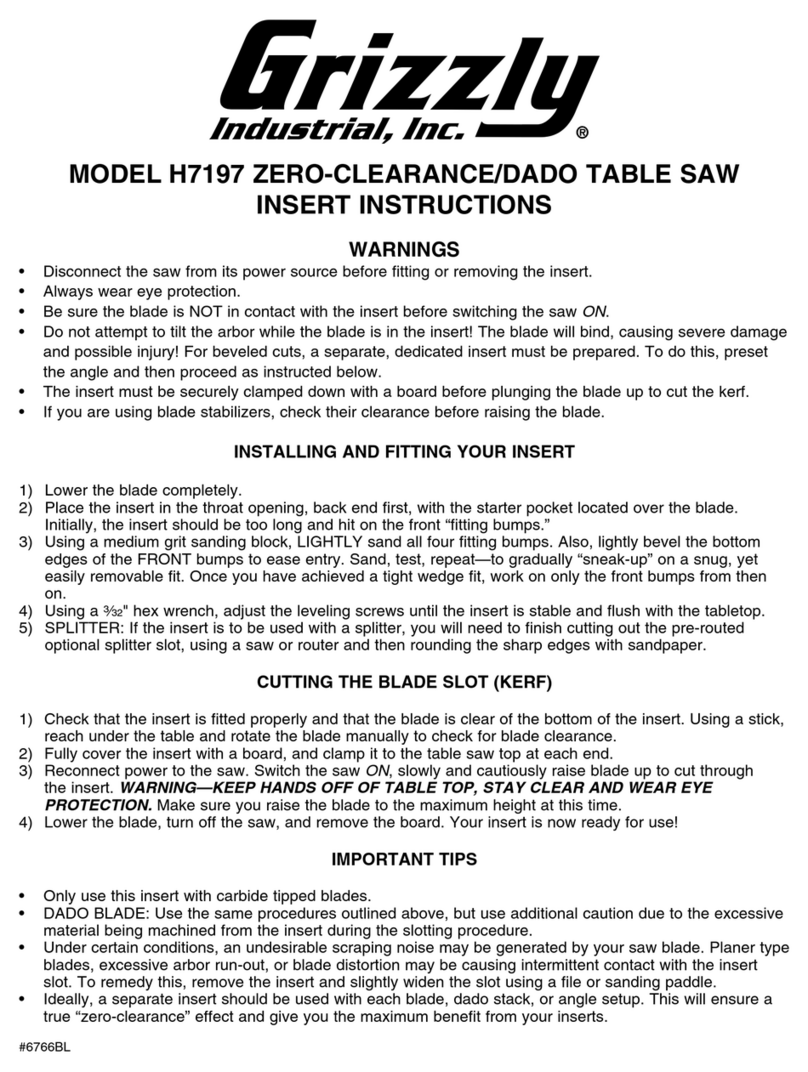

5. Tuck the plugs and cords around the top part

of the motor, then slide the motor cover over

the motor so that the switch cord strain relief

mounts to the slot in the cover.

6. Secure the motor cover to the aluminum

mounting plate with the three M4-.7 x 8 cap

screws.

7. Mount the switch in a convenient position on

your mill (see Figure 2 on Page 1).

If you need help with your new electric power

drawbar, call our Tech Support at: (570) 546-

9663.

Power Supply Circuit Requirements

You MUST connect the electric power drawbar to

a grounded circuit that is rated for the amperage

given below. Never replace a circuit breaker on

an existing circuit with one of higher amperage

without consulting a qualified electrician to ensure

compliance with wiring codes. If you are unsure

about the wiring codes in your area or you

plan to connect your machine to a shared cir-

cuit, consult a qualified electrician.

Minimum 220V Circuit Size ...................15 Amps

Full Load Amperage Draw

This machine draws the following amps under

maximum load:

Amp Draw ............................................. 7.5 Amps