WEARING PROPER APPAREL.

HAZARDOUS DUST.

HEARING PROTECTION.

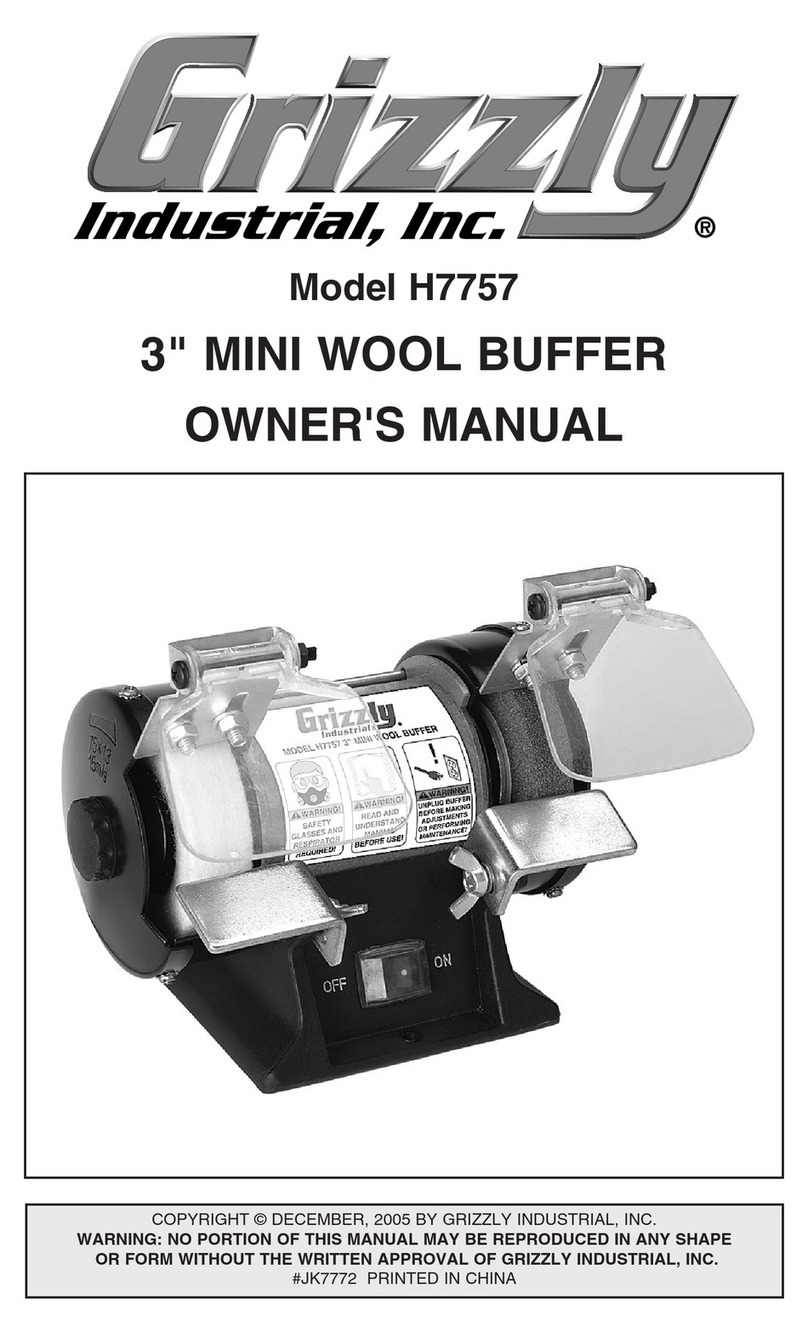

REMOVE ADJUSTING TOOLS.

INTENDED USAGE.

AWKWARD POSITIONS.

CHILDREN & BYSTANDERS.

GUARDS & COVERS.

FORCING MACHINERY.

NEVER STAND ON MACHINE.

STABLE MACHINE.

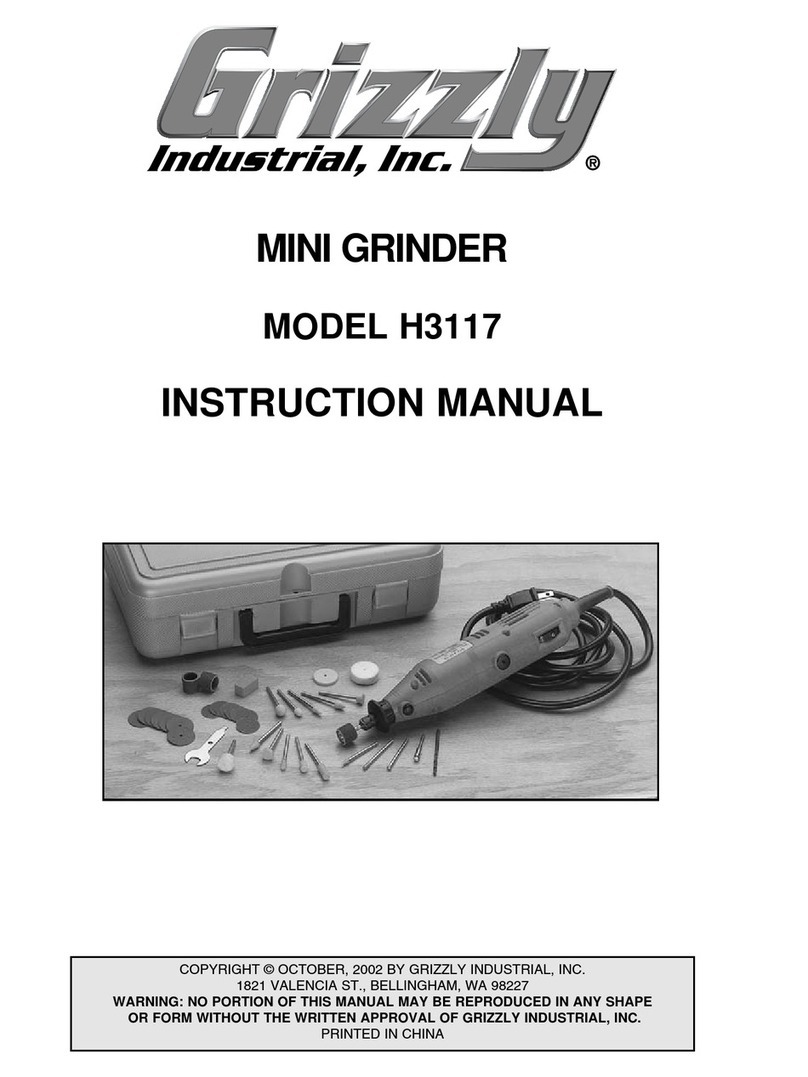

USE RECOMMENDED ACCESSORIES.

UNATTENDED OPERATION.

OFF

MAINTAIN WITH CARE.

CHECK DAMAGED PARTS.

MAINTAIN POWER CORDS.

EXPERIENCING DIFFICULTIES.