-2- Model H7509Z (Mfd. Since 01/21)

SECTION 1: SETUP

Unpacking

This cyclone dust collector stand was carefully

packaged for safe transport. When unpacking,

separate all enclosed items from packaging mate-

rials and inspect them for shipping damage. If

items are damaged, please call us immedi-

ately at (570) 546-9663.

IMPORTANT: Save all packaging materials until

you are completely satisfied with the stand and

have resolved any issues between Grizzly or the

shipping agent. You MUST have the original pack-

aging to file a freight claim. It is also extremely

helpful if you need to return your stand later.

Anchoring to Floor

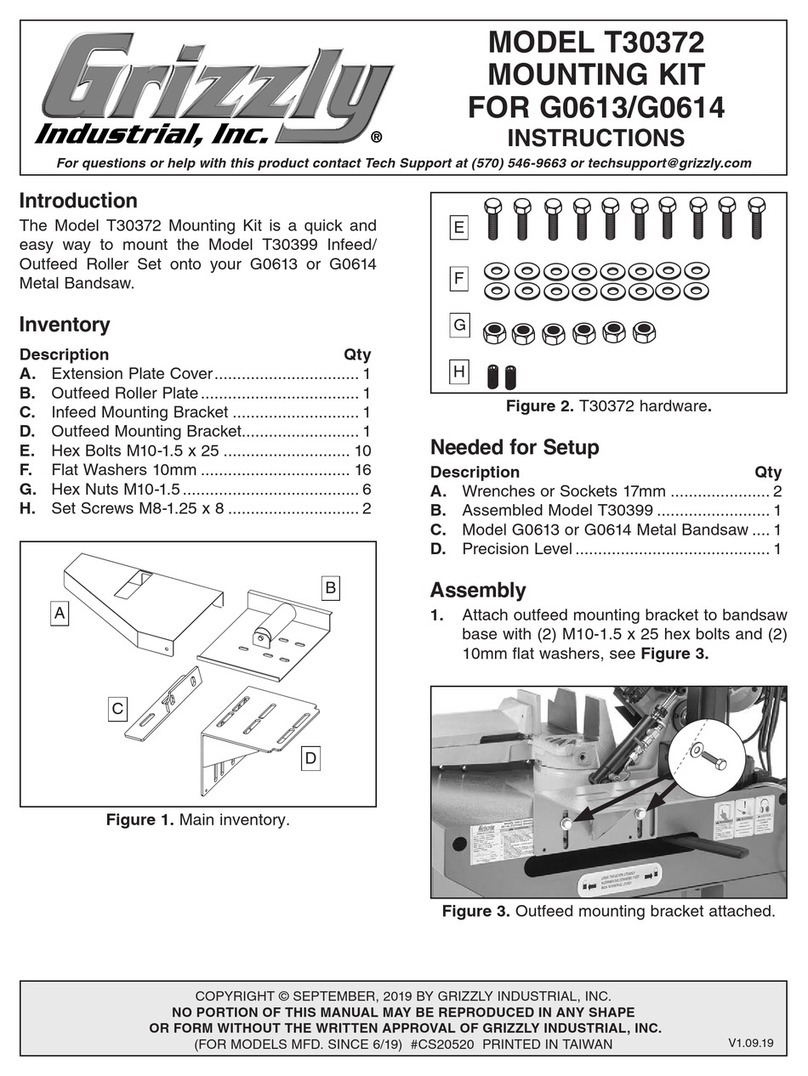

Figure 1. Popular method for anchoring

machinery to a concrete floor.

Anchoring to Concrete Floors

Number of Mounting Holes ............................ 4

Diameter of Mounting Hardware................. 1⁄2"

Anchoring machinery to the floor prevents tipping

or shifting and reduces vibration that may occur

during operation, resulting in a machine that runs

slightly quieter and feels more solid.

If the stand and machine will be installed in

a commercial or workplace setting, or if the

machine is permanently connected (hardwired) to

the power supply, local codes may require that it

be anchored to the floor.

If not required by any local codes, fastening the

stand to the floor is an optional step. If you choose

not to do this, we recommend placing your stand

on machine mounts, as these provide an easy

method for leveling and they have vibration-

absorbing pads.

Lag shield anchors with lag screws (see below)

are a popular way to anchor machinery to a con-

crete floor, because the anchors sit flush with the

floor surface, making it easy to unbolt and move

the stand and machine later, if needed. However,

anytime local codes apply, you MUST follow the

anchoring methodology specified by the code.

Stand or Machine Base

Concrete

Lag Screw

Lag Shield Anchor

Flat Washer

Drilled Hole

Needed for Setup

The following items are needed, but not included,

for the setup/assembly of this stand.

Description Qty

• Model G0441 (Mfd. 09.20+). ....................... 1

• Additional People ....................................... 1

• Lifting Equipment ........................................ 1

• Safety Glasses (For Each Person) ............. 1

• Wrench or Socket 1/2" ................................. 2

• 90° Square ................................................. 1

• Scrap Cardboard ........................ As Needed

• Wrench or Socket 9/16" ................................ 2

• Phillips Head Screwdriver #2 ..................... 1

• Wrench or Socket 8mm .............................. 1

• Open-Ended Wrench 30mm ...................... 1

Aside from the information in this manual, all other

content in the Model G0441 owner's manual and

manual update applies and MUST be read and

understood for your own safety. IMPORTANT:

Keep this manual with the G0441 owner's

manual for future reference.

For questions or help, contact our Tech Support