We are proud to offer the Hunter’s Meat

Cutting Bandsaw. When used according to

the guidelines stated in this manual, you can

expect years of trouble-free, enjoyable opera-

tion and experience proof of our commitment

to customer satisfaction.

The saw features a sheet steel body, easy to

clean stainless steel table, and a 101/4" cutting

height. It comes equipped with a 1720 RPM, 1

HP motor.

We are also pleased to provide this manual

with your saw. It was written to guide you

through assembly, review safety considera-

tions, and cover general operating proce-

dures. It represents our latest effort to pro-

duce the best documentation possible. If you

have any criticisms that you feel we should

pay attention to in our next printing, please

write to the customer service address listed

on your catalog: attn: Manager, Technical

Documentation.

Most importantly, we stand behind our

machines. If you have any service questions

or parts requests, please call or write us at the

appropriate customer service location listed

on your catalog.

To operate this or any power tool safely and

efficiently, it is essential to become as familiar

with its characteristics as possible. Take as

much time as necessary to become acquaint-

ed with your saw. The time you invest before

you begin to use your machine will be time

well spent. Also, read all of the safety proce-

dures. If you do not understand something

about this machine, DO NOT operate it.

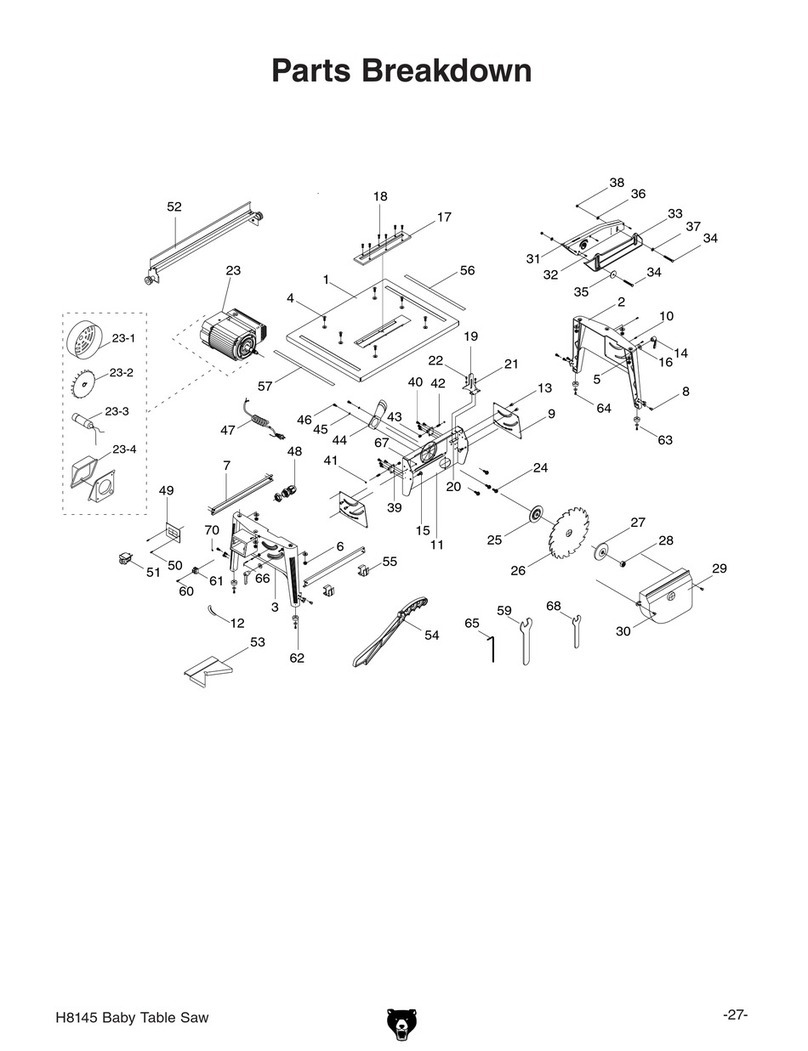

The specifications, drawings, and pho-

tographs illustrated in this manual represent

the Hunter’s Meat Cutting Bandaw as sup-

plied when the manual was prepared.

However, owing to our policy of continuous

improvement, changes may be made at any

Hunter’s Meat Cutting Bandsaw - 1 -

time with no obligation on our part. Whenever

possible, though, we send manual updates to

all owners of a particular tool or machine.

Should you receive one, we urge you to insert

the new information with the old and keep it

for reference.

The information in this manual has been

obtained from sources we believe to be reli-

able and as up-to-date as possible. We have

included some important safety measures

which we believe to be essential for safe oper-

ation. While most safety measures are gener-

ally universal, we remind you that each work

area is different and safety rules should be

considered as they apply to your specific situ-

ation. Also – please read the entire manual

before attempting to operate your saw.

We recommend that you keep a copy of our

current catalog for complete information

regarding our warranty and return policy.

Should you need additional technical informa-

tion relating to this machine, or if you need

general assistance or parts, please contact

the customer service department.

We also believe additional information

sources are very important for reaping the full

potential of this machine. Consulting with your

local butcher would be a good place to start.

WARNING! This saw is dangerous. Use the

tool with respect and caution to lessen the

possibility of mechanical damage or injury. If

normal safety precautions are overlooked or

ignored, injury to the operator or others in the

area is likely.

This bandsaw was specifically designed for

meat cutting. Modifications or improper use

of this tool will void the warranty. If you are

confused about any aspect of this machine,

DO NOT use it until you have resolved any

questions you have.

I. Introduction

End of Section