COPYRIGHT © JUNE, 2008 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#BL10789 PRINTED IN TAIWAN

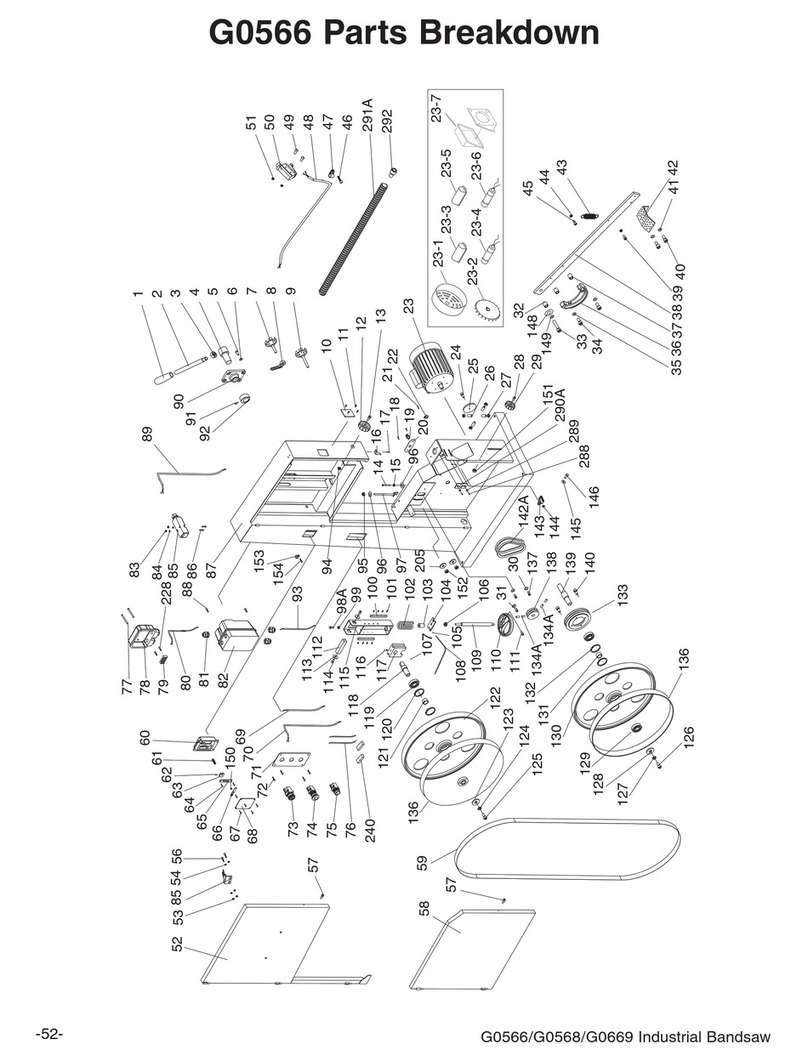

The Model G0531B/G0566B is the same as the Model G0566, except it has a magnetic brake motor, resaw

fence, and square fence rail. Besides the instructions, data sheet, circuit requirements, parts, and wiring

diagram in this insert, the content in the Model G0566 owner's manual is the same for both machines.

Before operating your new machine, you MUST read and understand this insert and the entire Model G0566

manual to reduce the risk of injury from improper use or setup.

If you have any further questions about this manual insert or the differences between the Model G0531B/

G0566B and the Model G0566, contact our Technical Support at (570) 546-9663 or email techsupport@

grizzly.com.

MODEL G0531B/G0566B

21" BANDSAW

w/MOTOR BRAKE

MANUAL INSERT

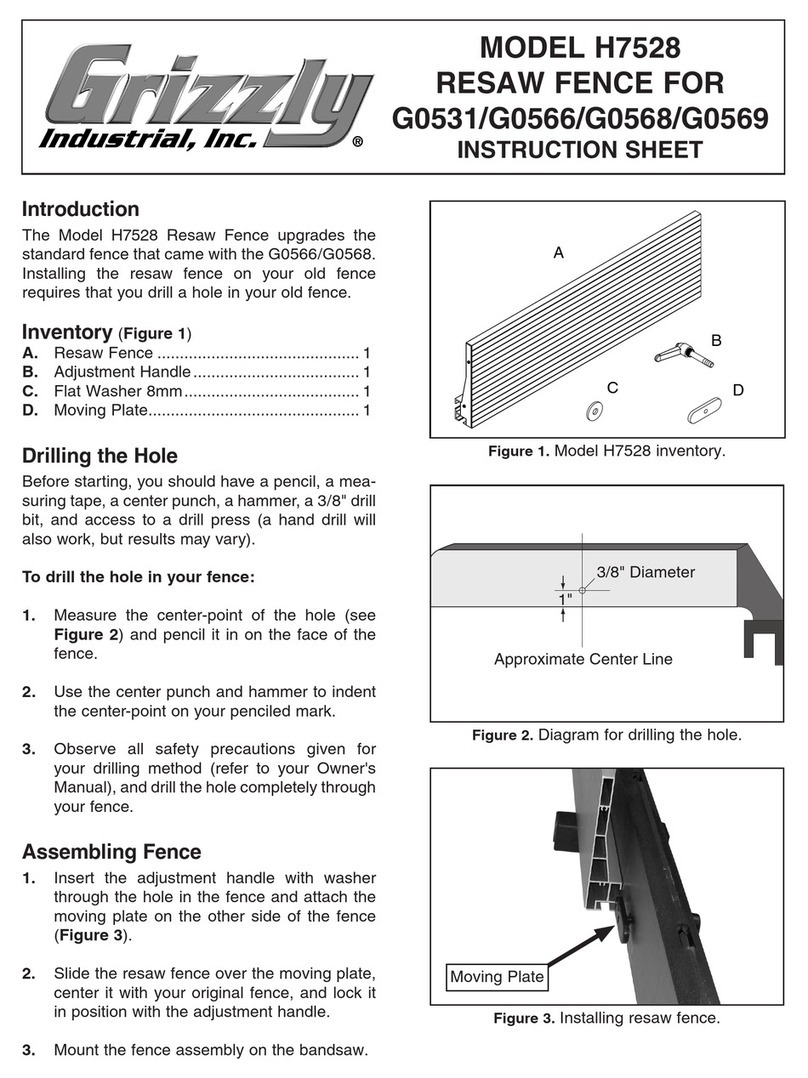

Machine Inventory

After all the parts have been removed from the

crate, you should have the following items:

Crate Contents (Figure 1): Qty

A. Bandsaw (not shown) ................................. 1

B. Miter Gauge ................................................ 1

C. Fence.......................................................... 1

D. Resaw Fence ............................................. 1

E. Guide Post Handwheel............................... 1

Figure 1. G0531B/G0566B inventory.

BC

ED

Hardware and Tools (not shown) Qty

Hex Wrench 5mm .............................................. 1

Hex Wrench 6mm .............................................. 1

Open End Wrench 10 x 13 ................................ 1

Open End Wrench 17 x 19 ................................ 1

Lifting Rings ....................................................... 2

Resaw Fence Lock Handle M8-1.25 x 44

(Fence) .............................................................. 1

Moving Plate M8-1.25 (Fence) .......................... 1

Flat Washer 8mm (Fence) ................................ 1

Installing Fence

Components and Hardware Needed: Qty

Fence Assembly ................................................ 1

Resaw Fence Assembly .................................... 1

Resaw Fence Lock Handle M8-1.25 x 44 ......... 1

Moving Plate M8-1.25 ....................................... 1

Flat Washer 8mm .............................................. 1

To install the fence:

1. Remove the cap screw, knobs, and washers

that hold the rail onto the table, then remove

the rail.

2. Flip the rail over and reinstall with the fast-

ners removed in Step 1.

3. Install the fence handle on the fence, if it is

not already installed.