Grohe Avensys Parts list manual

Other Grohe Plumbing Product manuals

Grohe

Grohe Europlus E User manual

Grohe

Grohe Ondus 45 983 User manual

Grohe

Grohe Concetto 32 207 User manual

Grohe

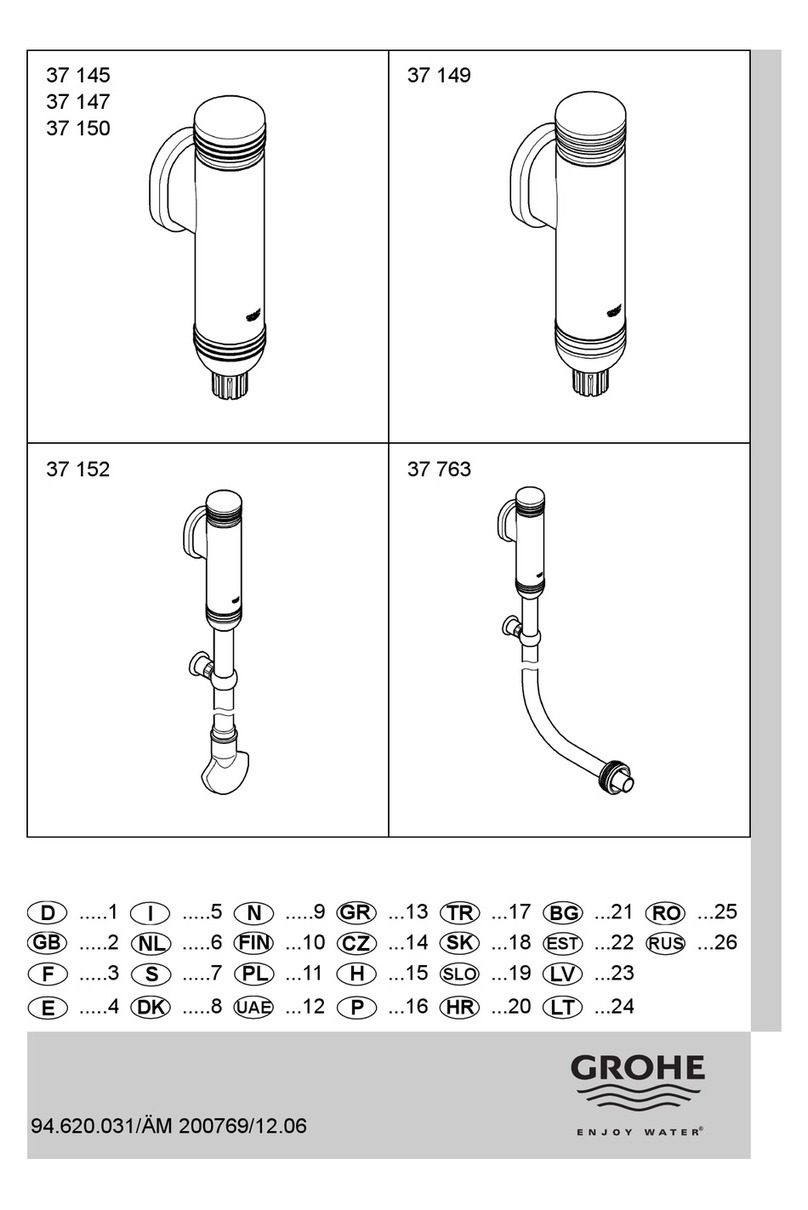

Grohe 37 145 User manual

Grohe

Grohe CONCETTO 30 273 User manual

Grohe

Grohe 37 338 User manual

Grohe

Grohe GROHTHERM 2000 NEW 34 169 User manual

Grohe

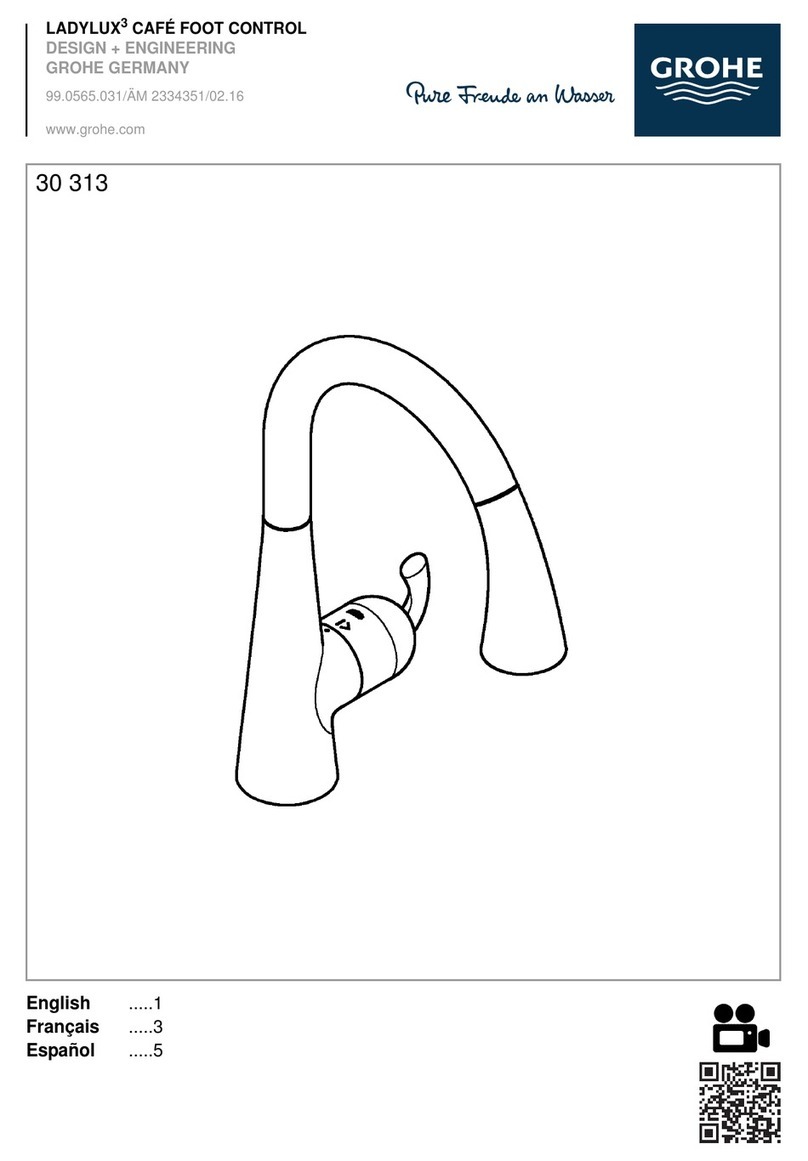

Grohe LADYLUX 3 CAFE FOOT CONTROL 30 313 User manual

Grohe

Grohe StartEdge Series User manual

Grohe

Grohe Allure 32 755 User manual

Grohe

Grohe Allure Brilliant 19 784 User manual

Grohe

Grohe 6094000 User manual

Grohe

Grohe Grohtherm 24076000 User manual

Grohe

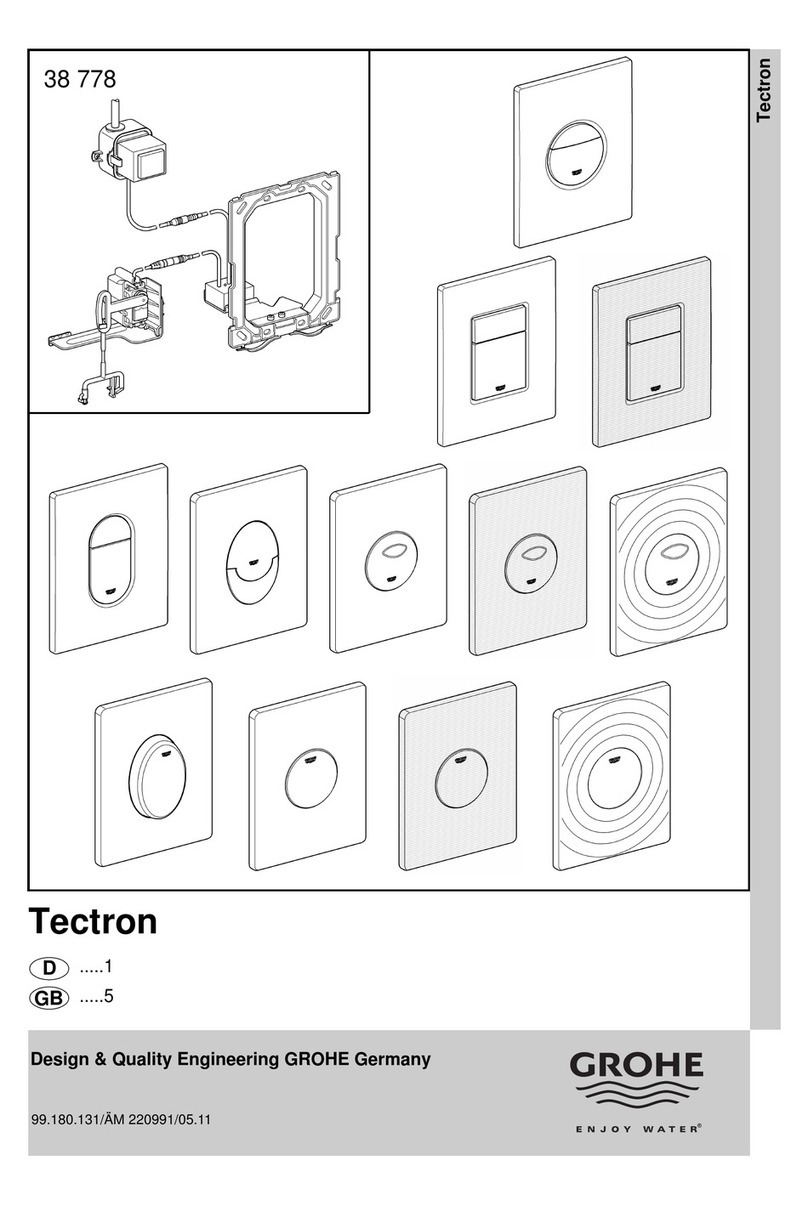

Grohe Tectron Owner's manual

Grohe

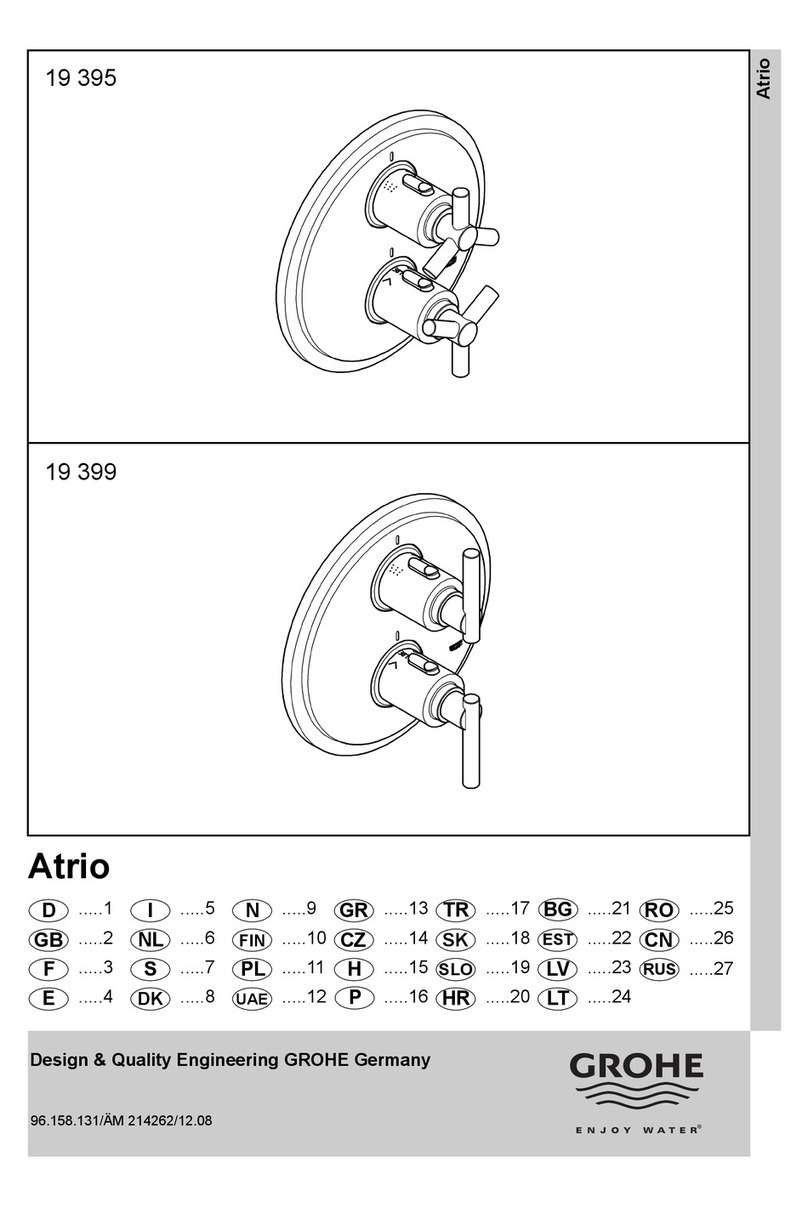

Grohe Atrio Series User manual

Grohe

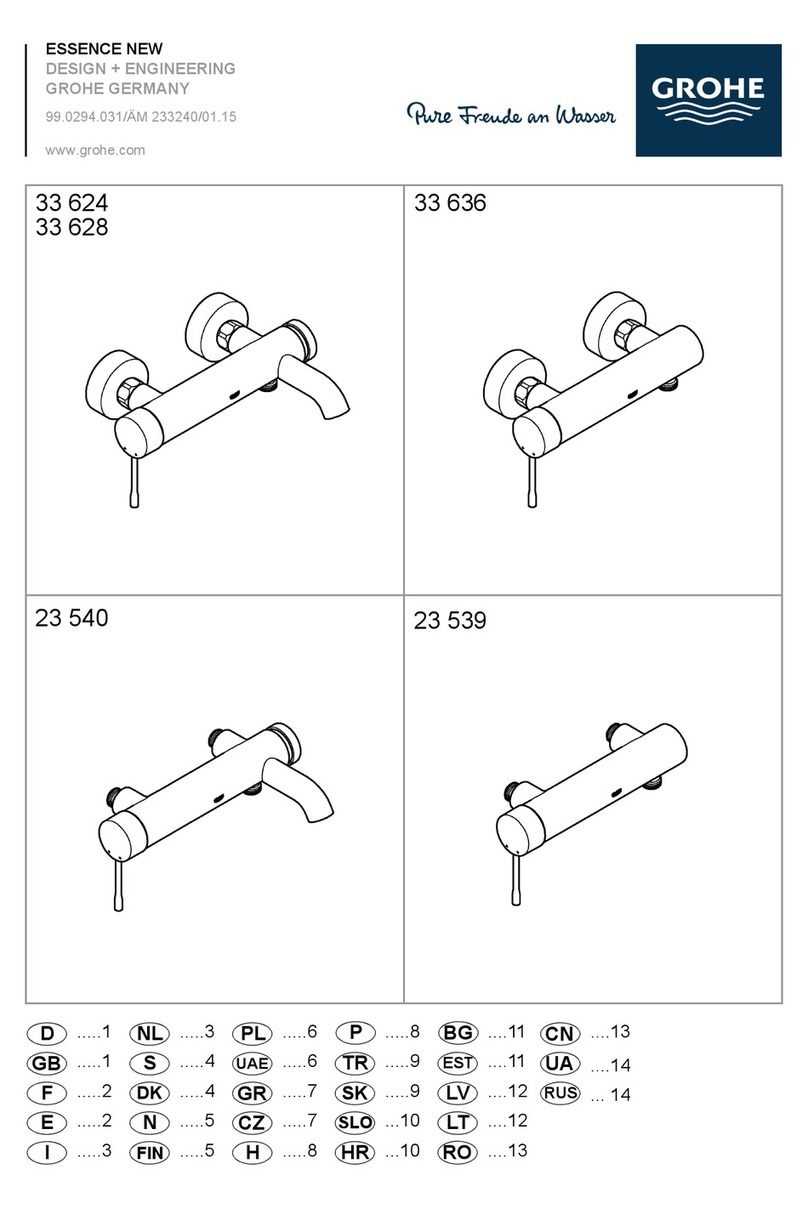

Grohe ESSENCE NEW 33 624 User manual

Grohe

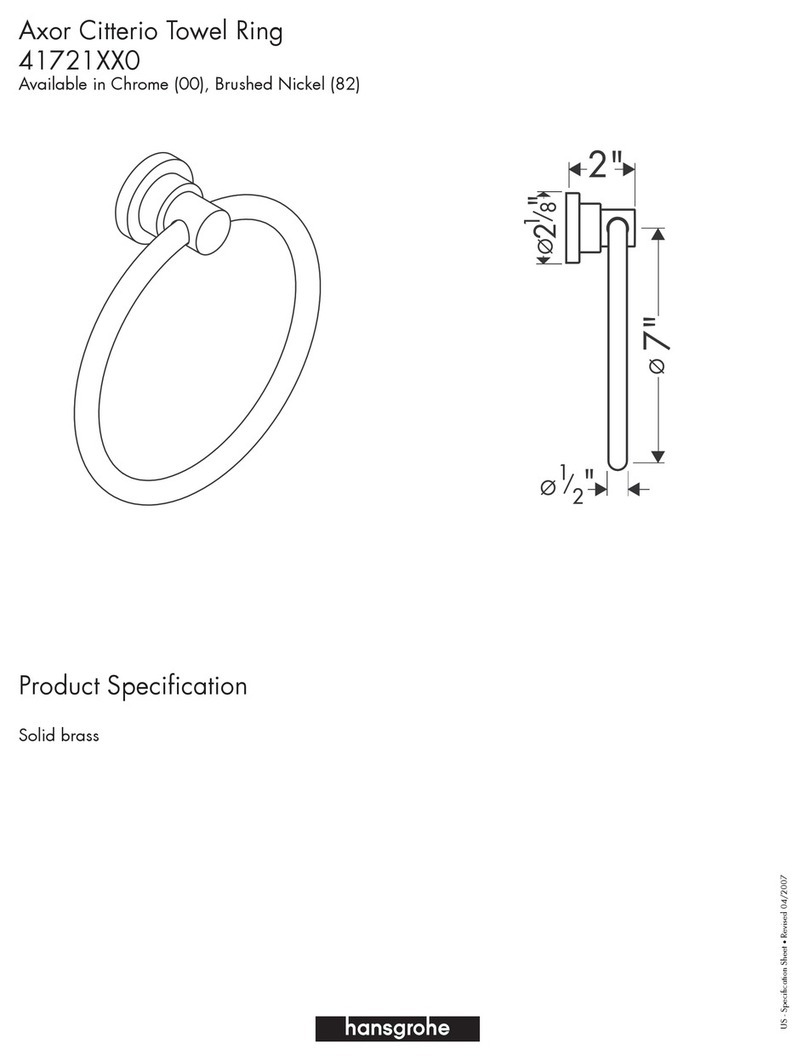

Grohe 41721XX0 User manual

Grohe

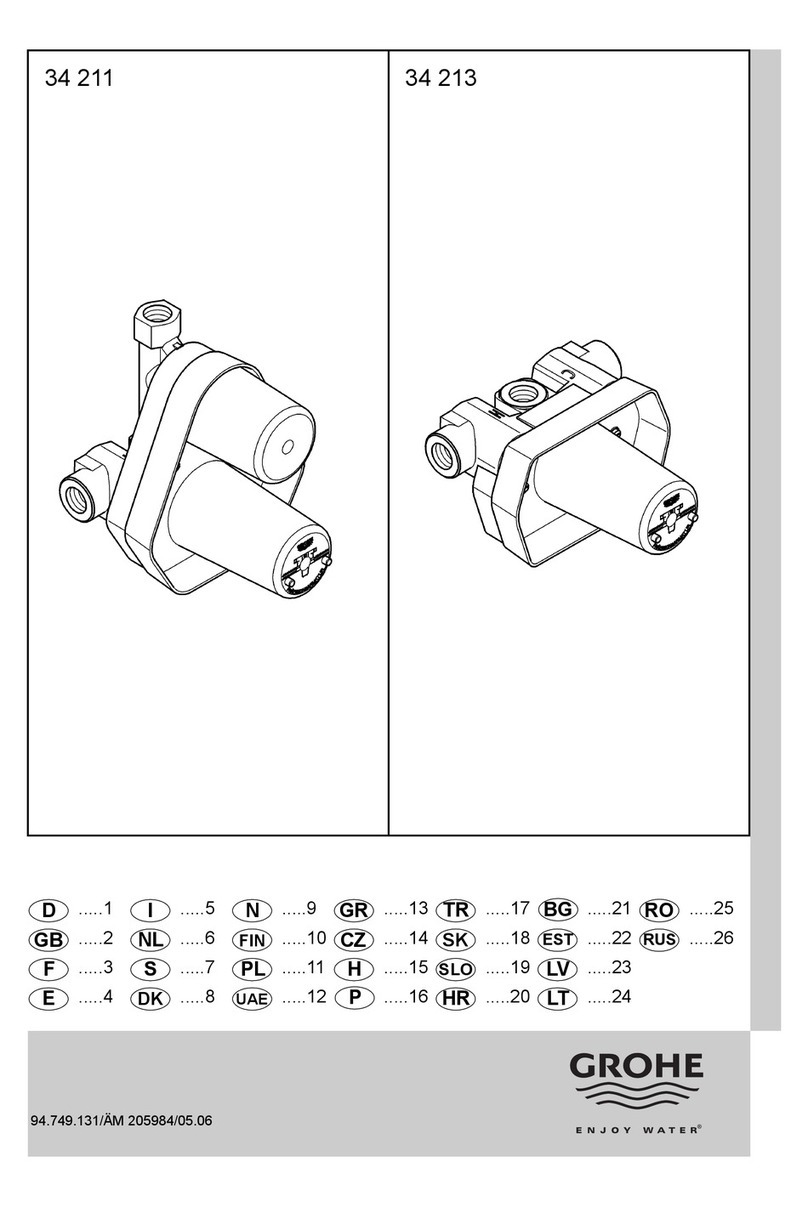

Grohe 34 211 User manual

Grohe

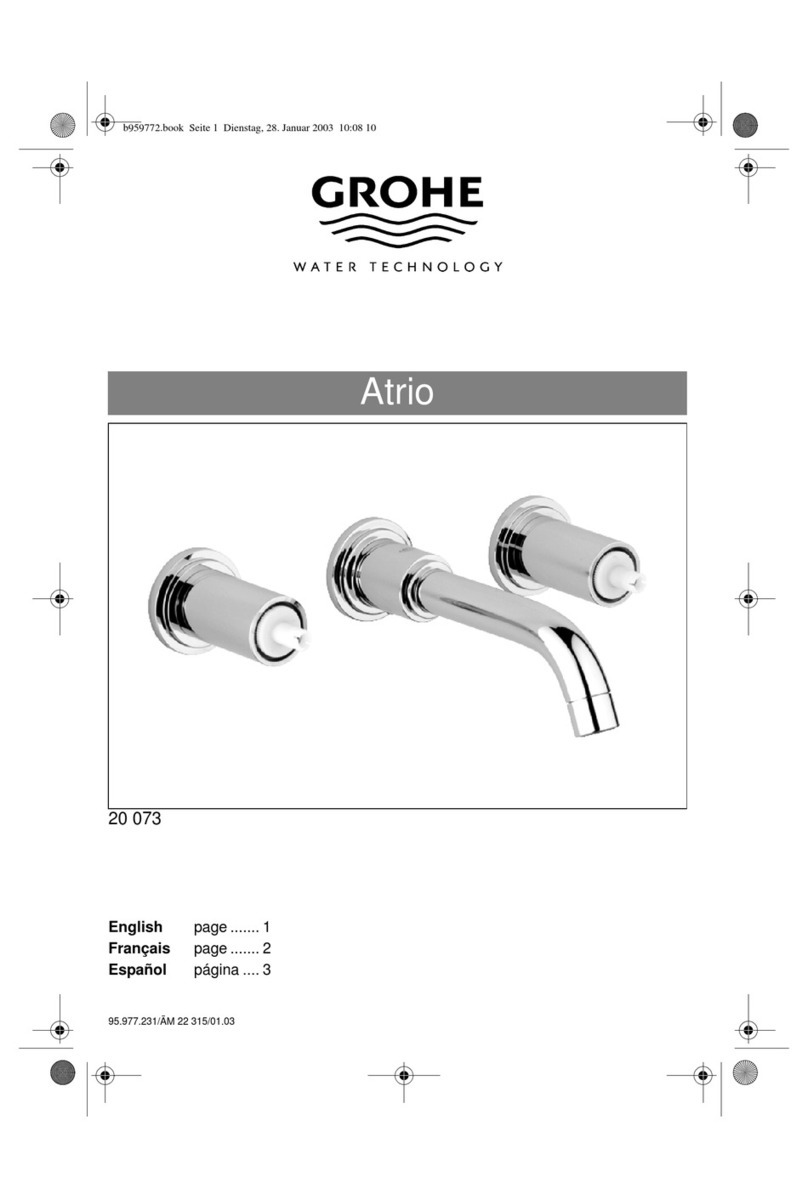

Grohe Atrio 20 073 User manual

Grohe

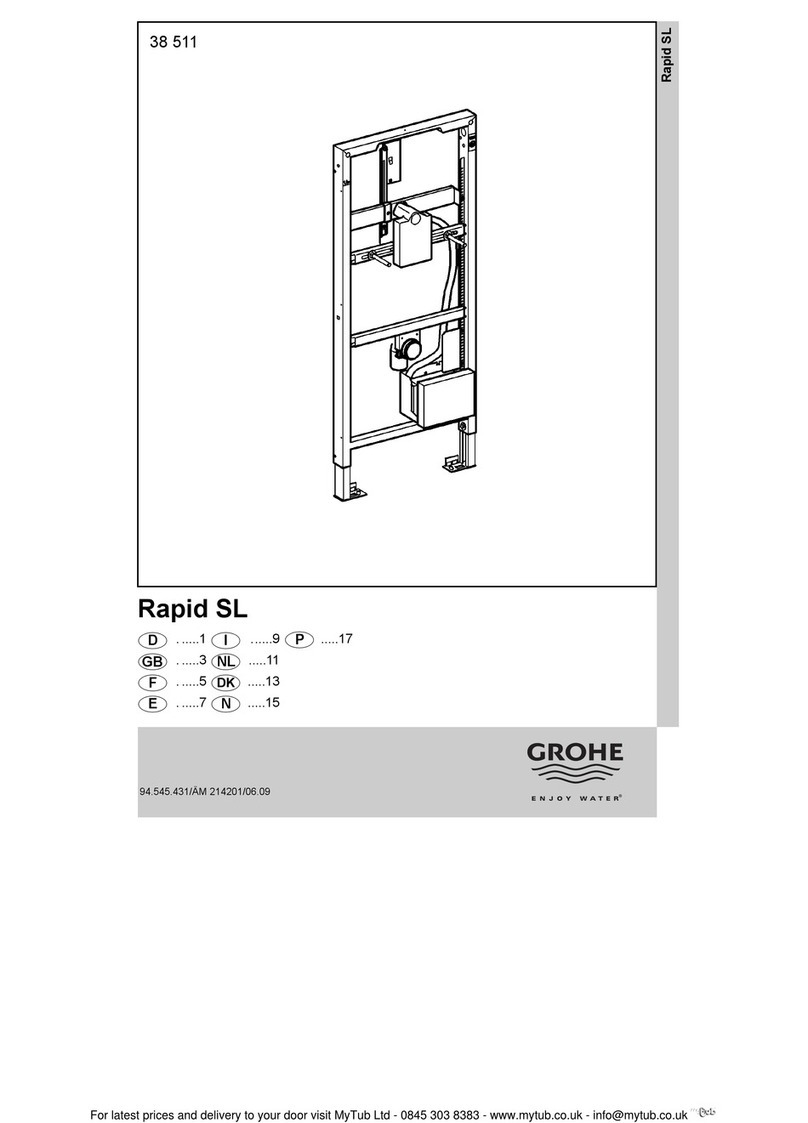

Grohe Rapid SL 38 511 User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide