Superstructure

3

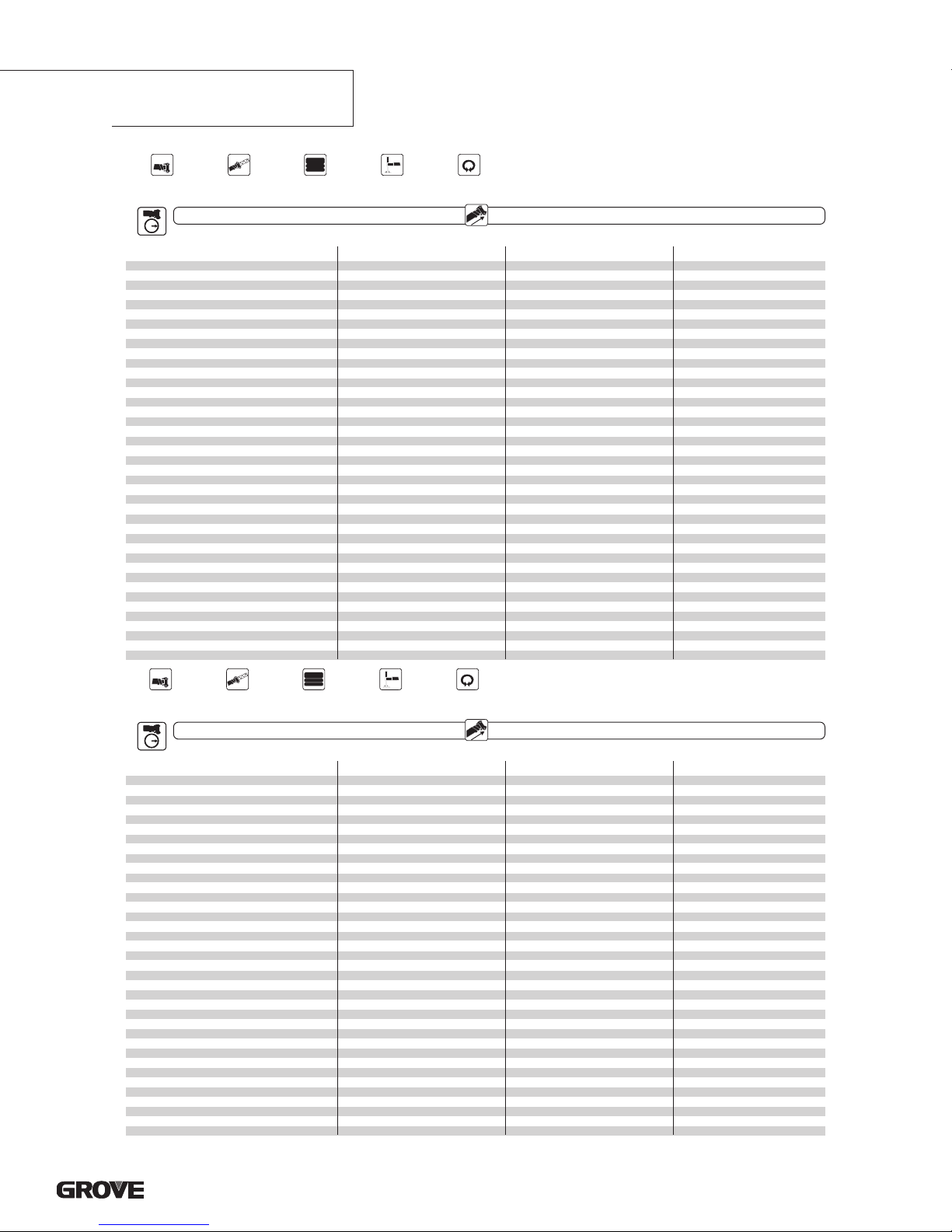

GMK6350

specifications

Boom

51 ft. - 197 ft. (15.5 m - 60 m) five section, full power

MEGAFORM™boom with patented TWIN-LOCK™boom pinning

system. Maximum tip height: 207 ft. (63 m).

Boom Elevation

Single lift cylinder with safety valve provides boom angle from -

1.5° to +82°.

*Telescopic Swingaway Extension

36ft. - 62 ft. (11m-19 m) telescoping offsettable swingaway

extension. Offsettable at 5° and 30°.

Lattice Jib

Luffing Jib is a lattice design with lengths of 69 ft. -200 ft. (21 m -

61m) in sections of 26 ft. (8 m). The luffing jib converts to a fixed

offset lattice jib using an offset angle adapter and provides

lengths of 62 ft. - 194 ft. (19 m - 59 m) offsettable at 3° and 25°.

MEGALIFT™ Attachment-Main Boom

Consists of a mast, pendant lines, and hydraulic tensioning

winch to support the main boom during lifting operations. Load

charts available for main boom only as optional equipment.

Load Moment & Anti-Two Block System

Load moment and anti-two block system with audio/visual

warning and control lever lockout provides electronic display of

boom angle, length, radius, tip height, relative load moment,

maximum permissible load, load indication and warning of

impending two-block condition.

Cab

All aluminum construction cab is tiltable (approximately 20°) and

includes safety glass and adjustable operator’s seat with

hydraulic suspension. Other features include engine dependent

hot water heater, armrest integrated crane controls, and

ergonomically arranged instrumentation.

Swing

3axial piston fixed displacement motors provide swing speed of

0-1.6 RPM thru planetary gear box. Also provided is a spring

applied, hydraulically released automatic swing brake with foot

operated release for free swing.

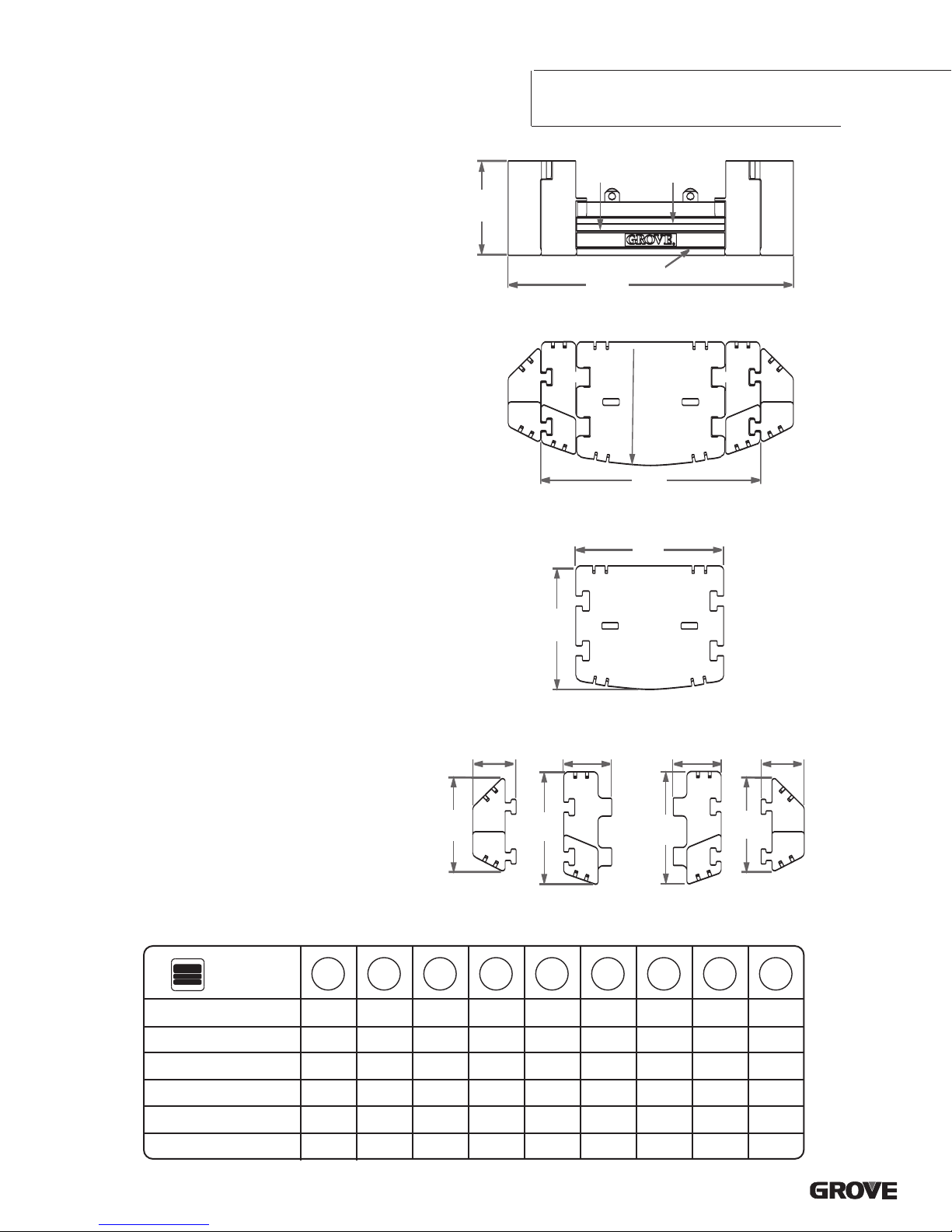

Counterweight

220,400 lbs. (100 Tonnes) consisting of various sections with

hydraulic installation/removal system (see counterweight

configuration on page 17).

Engine

Mercedes-Benz OM906LA, diesel, 6 cylinders, water cooled,

turbocharged, 275 HP (205 kW) at 1800 rpm.

Max. torque: 811 ft./lbs. (1100 Nm) at 1300 rpm.

Engine emission: EUROMOT/EPA/CARB.

Fuel Tank Capacity

87 gal. (330 L).

Hydraulic System

4separate circuits, 3 axial piston variable displacement pumps

with electronic power limiting control and 1 axial piston variable

displacement pump for slewing. Standard thermostatically

controlled oil cooler keeps oil at optimum operating temperature.

Tank capacity: 322 gal. (1220 L)

Control System

Full electronic control of all crane movements is accomplished

using electrical control levers with automatic reset to zero.

Controls are integrated with the LMI and engine management

system by CAN-BUS.

Hoist

Main and auxiliaryhoist are powered by axial piston variable

displacement motor with planetary gear and brake. “Thumb-

thumper” hoist drum rotation indicator alerts operator of hoist

movement.

Main Auxiliary

Line length: 984 ft. 1,378 ft.

(300 m) (420 m)

Rope diameter: 24 mm 24 mm

Line speed: 460 ft./min. 426 ft./min.

(140 m/min) (130 m/min)

Line pull: 24,700 lbs. 24,700 lbs.

(110 kN) (110 kN)

Electrical System

24 V system with three-phase alternator 28 V/80 A, 2 batteries 12

V/170 Ah.

*Optional Equipment

*Engine-independent diesel heater,with engine pre-heater

*Second spotlight

*Stereo/CD player

*Air Conditioning

*Stainless steel exhaust system

*MEGALIFT attachment

*Engine independent propane cab heater

*Auxiliaryboom nose

*Boom mounted work lights

*Aircraft warning light

*24 hr. timer for diesel heater

*Denotes optional equipment

Load Moment

&Anti-Two

Block System