65

Do not disassemble or alter the PACK to avoid heat ,explosion or fire.Do not use the PACK beyond specifide conditions.It might cause heat generation,damage,or deterioration of its performance.Do not throw,drop,hit,drive a nail in,stamp on the PACK.It may cause heat generation,explosion,or fire.In case of electrolyte leakage,keep leaked electrolyte away from contact with eyes or skin.immediately clean with water and seek helpfrom a doctor.Do not put the PACK into a fire.Do not use it or leave it on a place near fire,heaters,or high temperature sources.It may cause over temperature,explosion or fire.Do not submerge the PACK in water,or wet the product.It may cause heat generation,explosion ,or fire.Do not reversely connect the PACK positive(+)and negative(-)terminal.Do not short circuit by letting the PACK terminals(+and -)contact a wire or any metal.The unit is heavy enough to cause severe injury.Keep out of reach of children or animals.WARNINGX

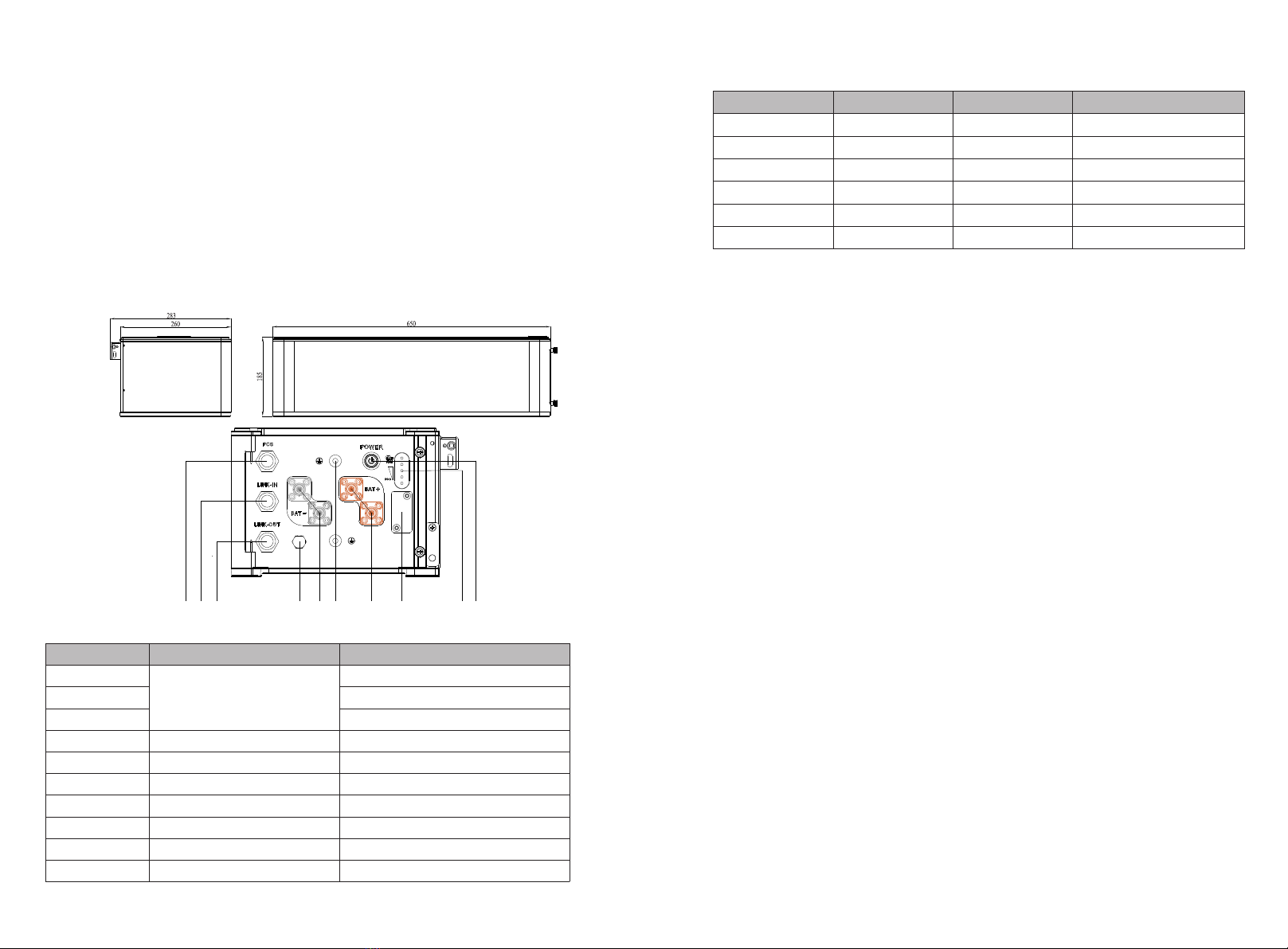

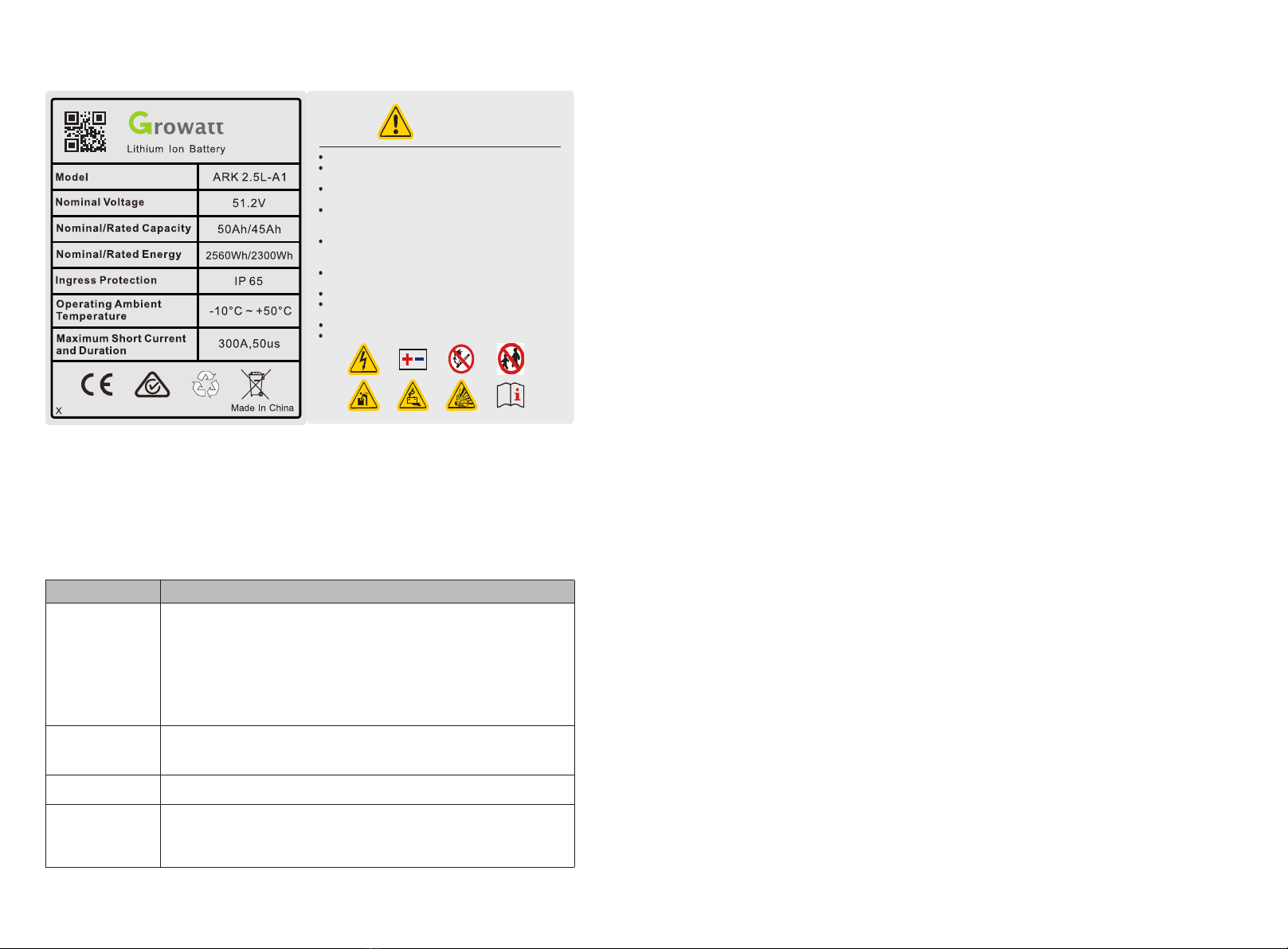

Fig 2.1: Nameplate Fig 2.2: LabelNote: When the ambient temperature is between -10 ℃ and 0℃, the maximum charging current of the battery is 2.5A.2.4 Emergency ResponsesManufacturer takes foreseeable risk scenarios into consideration and is designed to reduce hazards and dangers. However, if the following situation occurs, do as below:

Description and action need

Avoid touch of leaking liquid or gas. If you touch the leaking electrolyte, do as below immediately.Inhalation: Evacuate the contaminated area, and seek medical help.Eye contact: Rinse eyes with flowing water for 15 minutes, and seek medical help.Skin contact: Rinse contacted area thoroughly with soap and water, and seek medical help.Ingestion: Vomiting, and seek medical help.

It's hard for PACK systems ignite spontaneously. If the PACK has caught a fire, do not try to extinguish the fire but evacuate people immediately.

If PACK is flooded or submerged, do not access it. Contact Growatt or distributor for technical assistance immediately.

Damaged PACKS are dangerous and must be handled with special attention. They are no longer suitable for use and may cause danger to people. If the PACK damaged, stop use it and then contact the Growatt or distributor.

Storage and Transportation 33.1 Storage RequirementsØPlace the PACK follow the identification on the packing case during storage.ØDo not put the PACK upside down or sidelong. ØThe defective PACK needs to be separated from other PACKs. ØThe storage environment requirements are as follows: Install the PACK in a dry and clean place with proper ventilation.The storage temperature for a short week is between -30°C to 60℃.If you store the PACK over a long period of six months, the storage temperature is between-20°C to 50°C, relative humidity: 5%~95%RH. Place the PACK away from corrosive and organic substances (including gas exposure). Free from direct exposure to sunlight and rain .At least two meters away from heat sources (such as a radiator). Free from exposure to intensive infrared radiation. Note: If a PACK is useless for six months, it needs to be recharged.3.2 Transportation RequirementPACK has been certified in UN38.3 (Section 38.3 of the sixth Revised Edition of the Recommendations on the Transport of Dangerous Goods: Manual of Tests and Criteria) and SN/T 0370.2-2009 (Part 2: Performance Test of the Rules for the Inspection of Packaging for Exporting Dangerous Goods). PACK is classified as category 9 dangerous goods.ØThe PACK shall not be transported with other inflammable, explosive or toxic substances.ØEnsure the original Package and label complete and recognizable.ØProhibit direct exposure to sunlight, rain, condensing water caused by temperature difference and mechanical damages.ØProhibit to pile up more than six PACKs.ØThere will be a drop in capacity during transportation and storage.Ø Transportation temperature is between-20°C to 50°C, relative humidity: 5%~95%RH.Recharge procedures 1.Identify the PACK that needs recharging;2.Refer to quick installation guidance, complete the installation and wire connection. Ensure PACK in off status during all the steps.3.Set the power system as “CC=25A, CV=55.8V” , activate the PACK and start recharging.4.Recharge until LED2 flicks.5.Having completed recharge, leave circuit open for five minutes before check voltage. If voltage is not less than 52V, the recharge is successful.