Hog Slat Inc. Newton Grove, NC USA September 2014

1

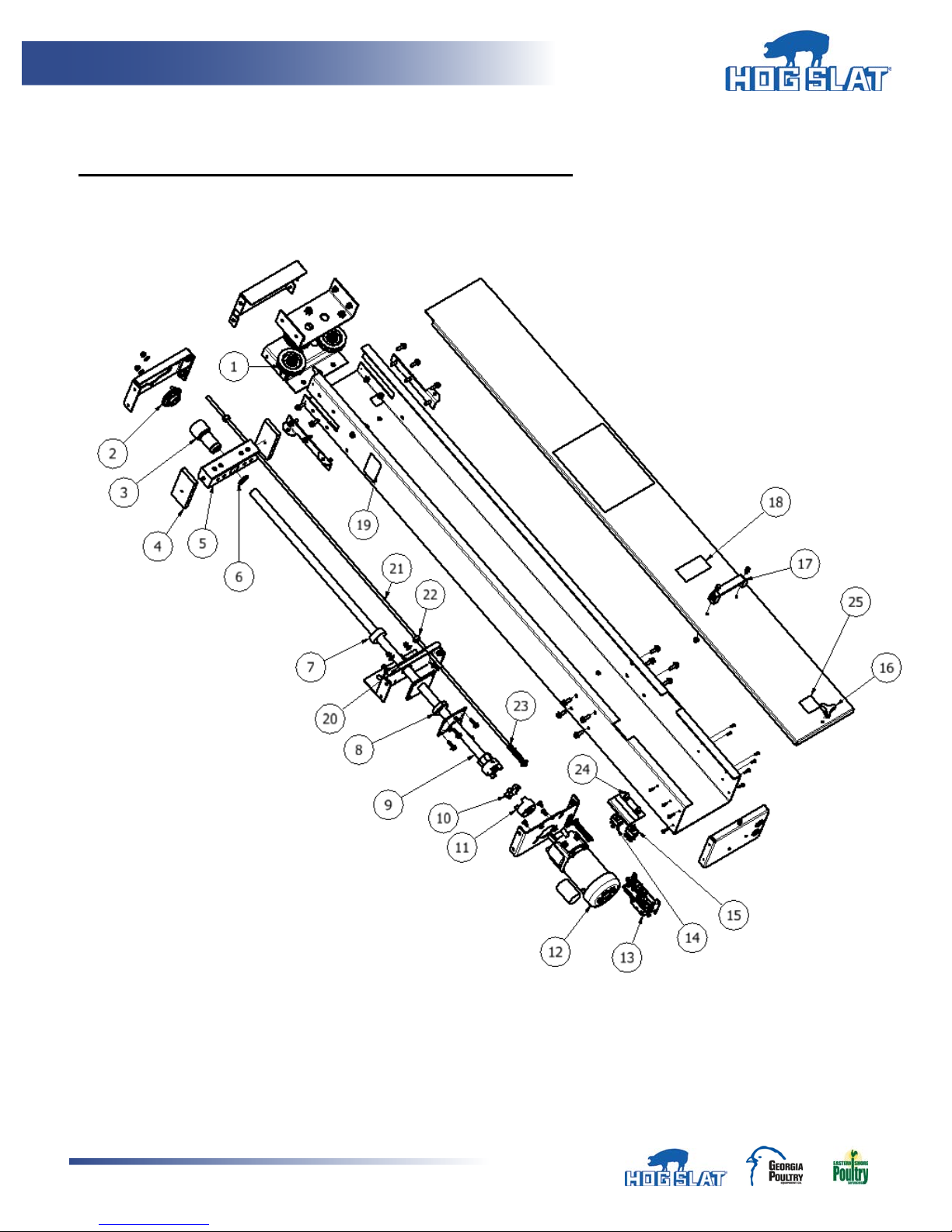

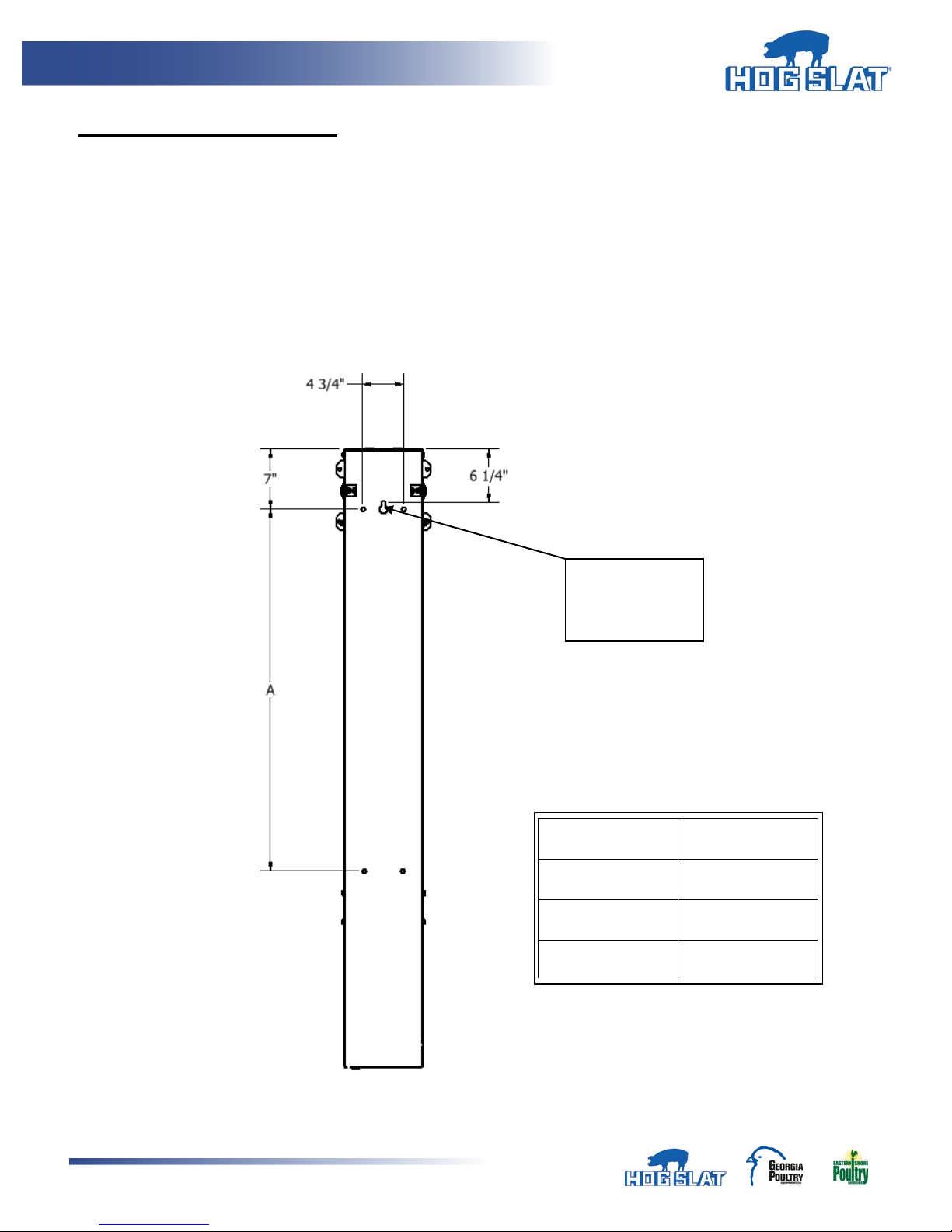

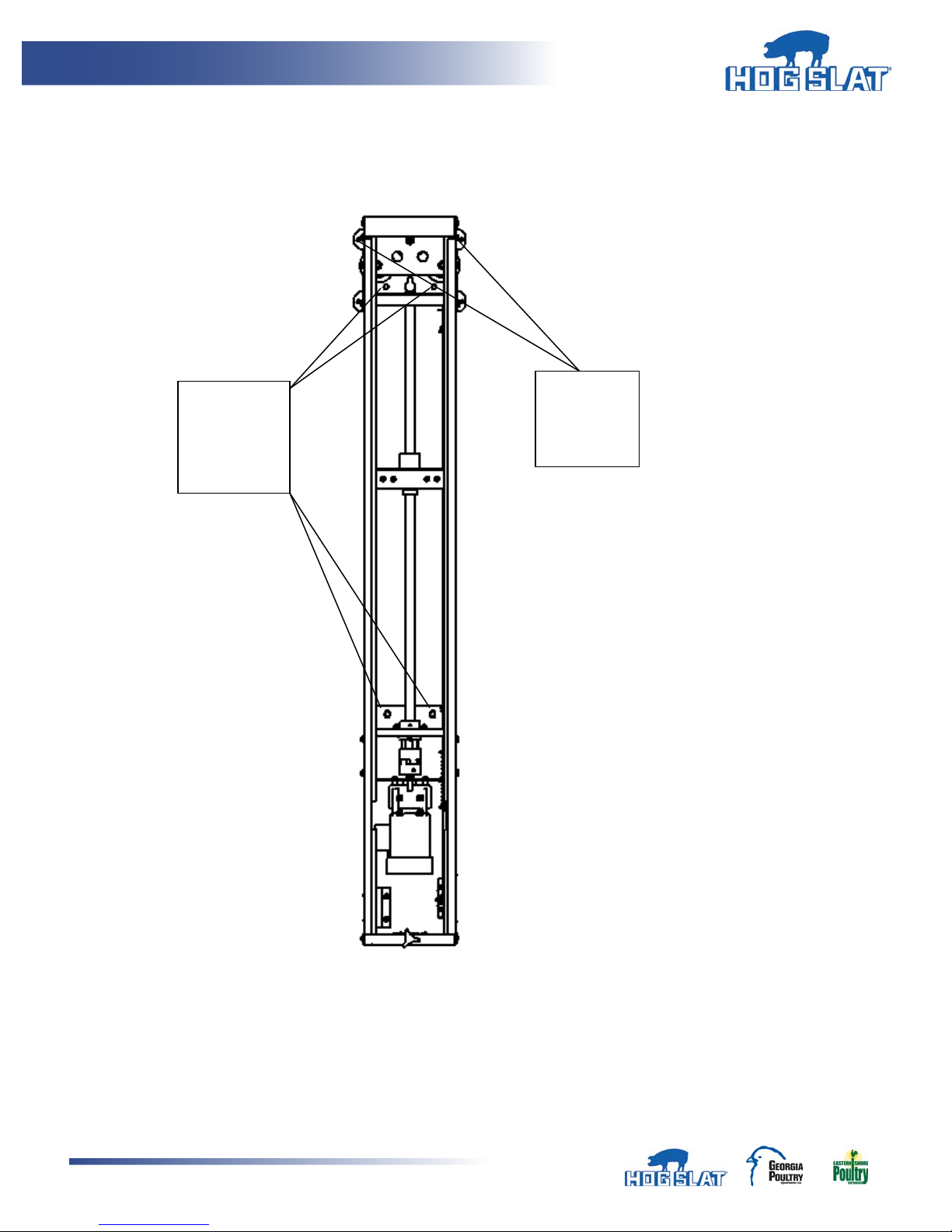

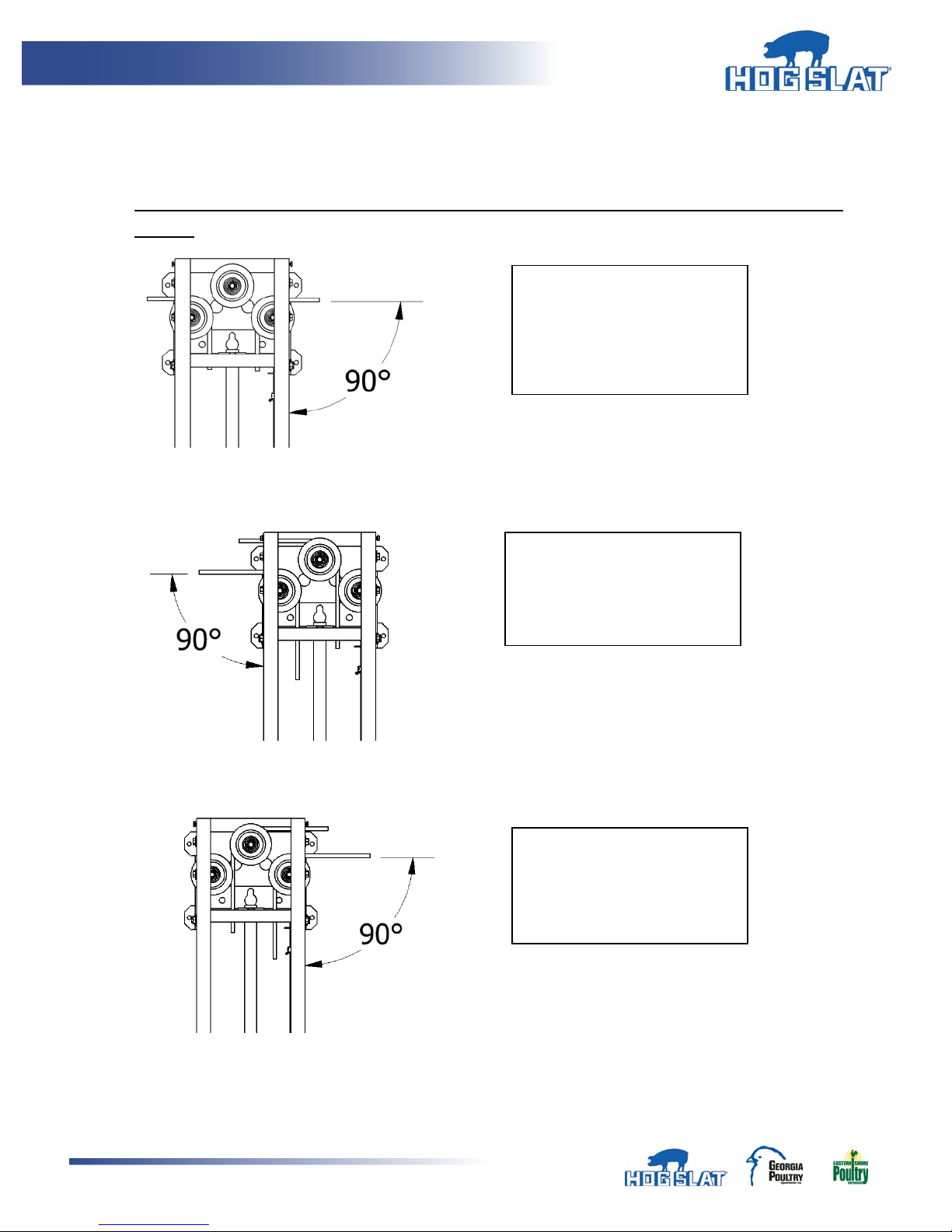

HS583 Curtain/Vent Machine Installation Manual

General Installation Notes:

Make sure that power is disconnected from system prior to servicing.

Installation of this equipment and related OEM equipment should be in accordance with these

instructions, OEM’s installation instructions and local codes (if applicable). Failure to follow specified

instructions may cause damage to equipment and/or personal injury or death.

Take special note of any Warnings or Safety Decals on the equipment and in manuals.

Always wear protective clothing and any applicable Personal Protective Equipment (Safety Glasses

and/or Ear Plugs) when working with the equipment.

Discarded materials, equipment and boxes should be recycled in accordance with local and national

codes.

Note: Actuator Assembly is to be wired in accordance with all applicable local and national electrical wiring codes. All

wiring sizes and fuse capacities are to be sized according to applicable electrical code specifications or other regulations.

SAFETY INSTRUCTIONS:

Read all safety messages in this manual and on equipment safety decals. Follow recommended

precautions and safe operating practices.

Ground all electrical equipment for safety.

Ground all non-current carrying metal parts to guard against electrical shock.

Always keep safety decals in good condition and replace missing or damaged decals.