3

GETTING STARTED

CARTRIDGE LOADING

BULK LOADING

TRANSFER PUMP LOADING

1. Removing empty cartridge: Remove any cartridge in the

grease gun barrel prior to refilling. To check if a cartridge is

in the barrel, first compress the spring by pulling the plunger

handle fully outward & latch the plunger rod in the slot on

the end cap. Remove the grease gun head by turning it

anticlockwise to remove any empty cartridge.

2. Locking / Releasing the plunger rod: This gun incorporates

a groove in the plunger rod that is latched onto a slot in the

end cap to hold the plunger rod when fully extended. Before

pushing the plunger rod into the barrel, simply release it from

the slot, allowing it to slide forward.

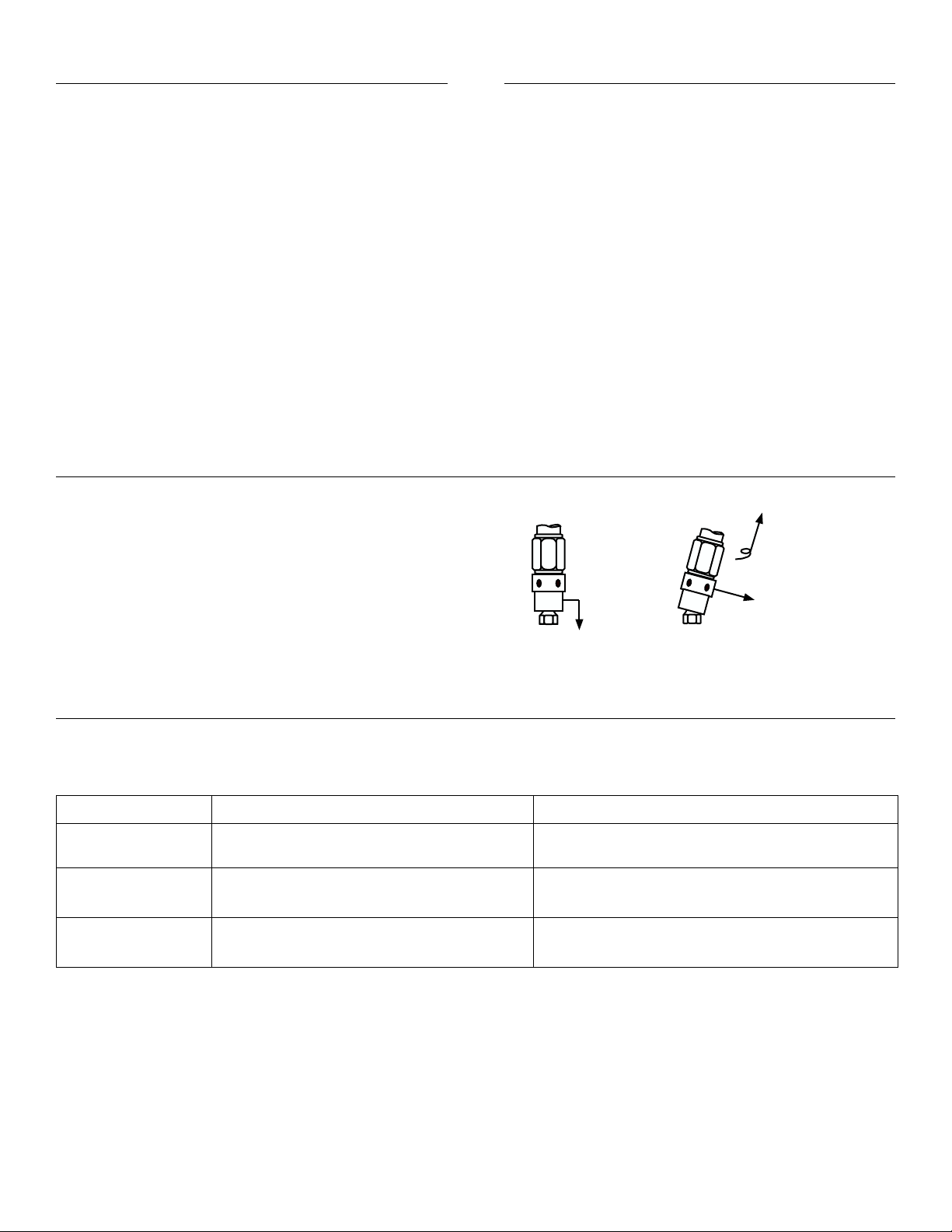

3. Priming: Usually after loading, all grease equipment have

some trapped air pockets in grease . Trapped air causes zero

or reduced grease discharge. Removing these air pockets

from grease is referred to as Priming or Air Bleeding. It is

highly recommended to prime the grease gun after every

loading.

1. Pull the plunger rod fully

backwards and latch the

plunger rod groove into the

slot on the end cap of the

grease barrel.

1. Unscrew the grease barrel

from the gun head by rotating

anti-clockwise. Insert the

open end of the barrel about

2” into the grease container.

1. Wipe the grease gun’s bulk

loader valve free of grease and

possible debris. Activate the

transfer pump until a small

amount of grease comes

out. This step will minimize

transferring any trapped air.

2. Unscrew the grease barrel

from the gun head by

rotating anti-clockwise.

3. Carefully release the plunger handle to eject the empty

cartridge from grease barrel.

4. Remove the plastic cap

from the grease cartridge

and insert cartridge into

the grease barrel.

5. Remove the pull tab from grease

cartridge and screw grease

barrel into gun head.

6. Release air from grease by

following Priming Instructions.

2. Slowly pull the plunger handle back to draw in grease into

the empty barrel while pushing the grease barrel deeper into

the grease until the plunger rod is fully extended. This will

prevent air pockets from being pulled into the grease barrel.

3. The grease gun barrel should now be filled with grease. The

outside surface may have a lot of grease stuck to it and

should be wiped clean for safety.

4. Shake the grease gun barrel to allow grease to settle down.

Screw back the grease gun head tightly onto the barrel.

5. Release air from grease by following Priming Instructions.

Bulk loader valve

2. Engage the plunger rod with

the follower by rotating the

plunger handle. Connect the

Bulk Loader Valve tightly on

the grease gun to the loader

adapter on the transfer pump

line.

3. Start operating the transfer

pump, keeping your hand on

the grease gun, lightly pushing

it down onto the transfer

pump.

4. Once the gun barrel is filled, pumping would get very

hard. The follower rod will be extended approximately 8

inches exposing the plunger rod groove. Stop at this time.

Disconnect the Bulk Loader Valve from the transfer pump line.

5. Release air from grease by following Priming Instructions.