PAGE 1 of 2 LIT-003-168

Positioning Vise For Engravers and Jewelers Using a Microscope

INSTRUCTIONS • #003-541

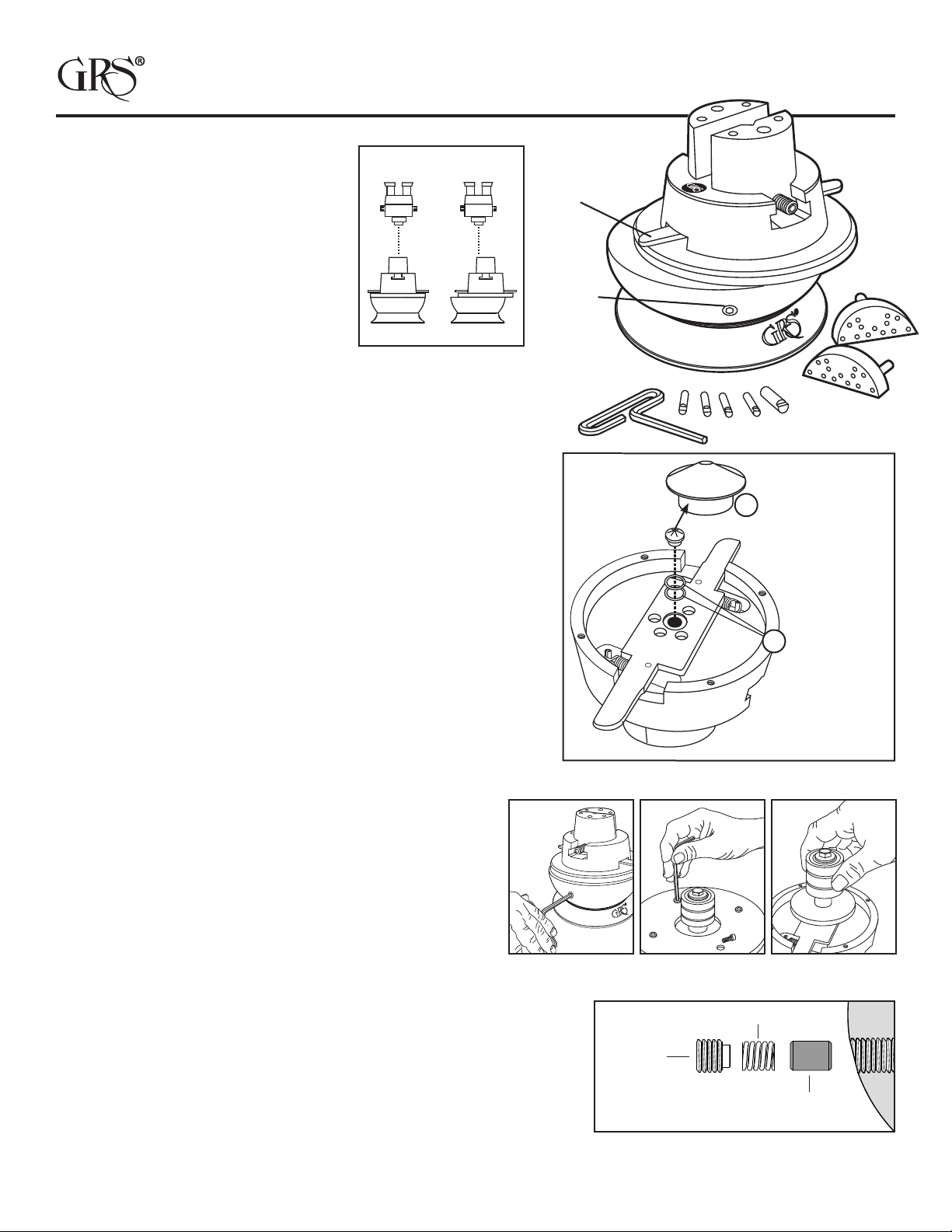

How To Position

Make sure the vise head is in the center

of the vise base. Place the vise directly in

the center under the microscope (FIG. 1).

Pressing the “Release Lever” will free

the vise head so that it may be moved or

slide in any desired direction. Release the

lever and the vise head locks in place and

will rotate from that desired point (FIG. 2).

Users will quickly learn to position the

vise while looking through the scope.

Maintenance

Based on usage, open jaws fully and clean any dirt and metal pieces

from the threads. After cleaning, apply a small amount of light oil to

the threads.

Wear Repair

Parts that may wear and eventually need replacing are the “Lock

Button” (FIG. 3.A) located at the center of the position release lever and

the “Jaw Thread Pins” (FIG. 8) located in each jaw.

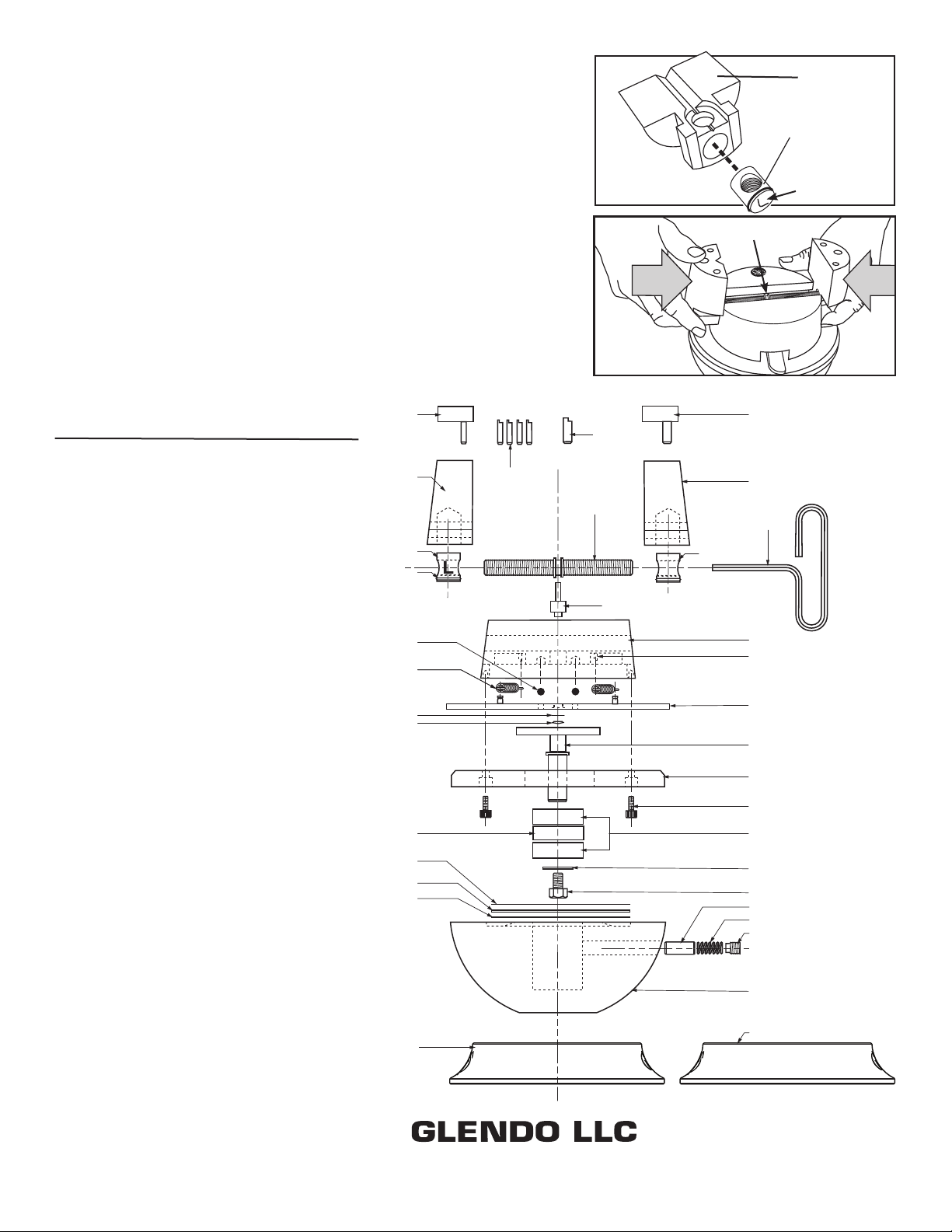

Loss of Locking Tension

If the vise head does not stay in locked position, tighten the tension.

Loosen the Rotational Drag Screw located on the side of the ball

(FIG. 4). Lift the upper portion of the vise out of the base. Turn the vise

head upside down and rest it on its top.

Remove the four hex head bolts (FIG. 5) from the mounting plate and

lift the plate off. Set the bearing / post assembly (FIG. 6) to the side. The

lock button (FIG. 3.A) is now visible in the center of the lever handle.

Remove the lock button with a small screwdriver by prying it up.

The button should have a 3/32" at in the center of the crown. If the

button is damaged or excessively worn, we recommend replacing

it. If it looks in good shape, you can add tension by placing shim

washers (FIG. 3.B) under the button. This will raise it to create more

locking tension.

Reassemble the vise by placing the bearing / post in the center

of the vise head as shown in Figure 6. Set the mounting plate

over the bearing/post and align the bolts.

Pull the release lever open to move the vise head. Hold it in

that position and then tighten the four bolts down. Hold the

lever open when tightening the bolts or damage to the lock

button will occur.

Place the vise head into the base and tighten the ball swivel

tension screw (FIG. 4).

FIG. 1 FIG. 2

Lock Button 3/32"

Flat center peak

Shim

Washers

FIG. 4 FIG. 5 FIG. 6

Rotational

Drag

Screw

Position

Release Lever

A

B

FIG. 3

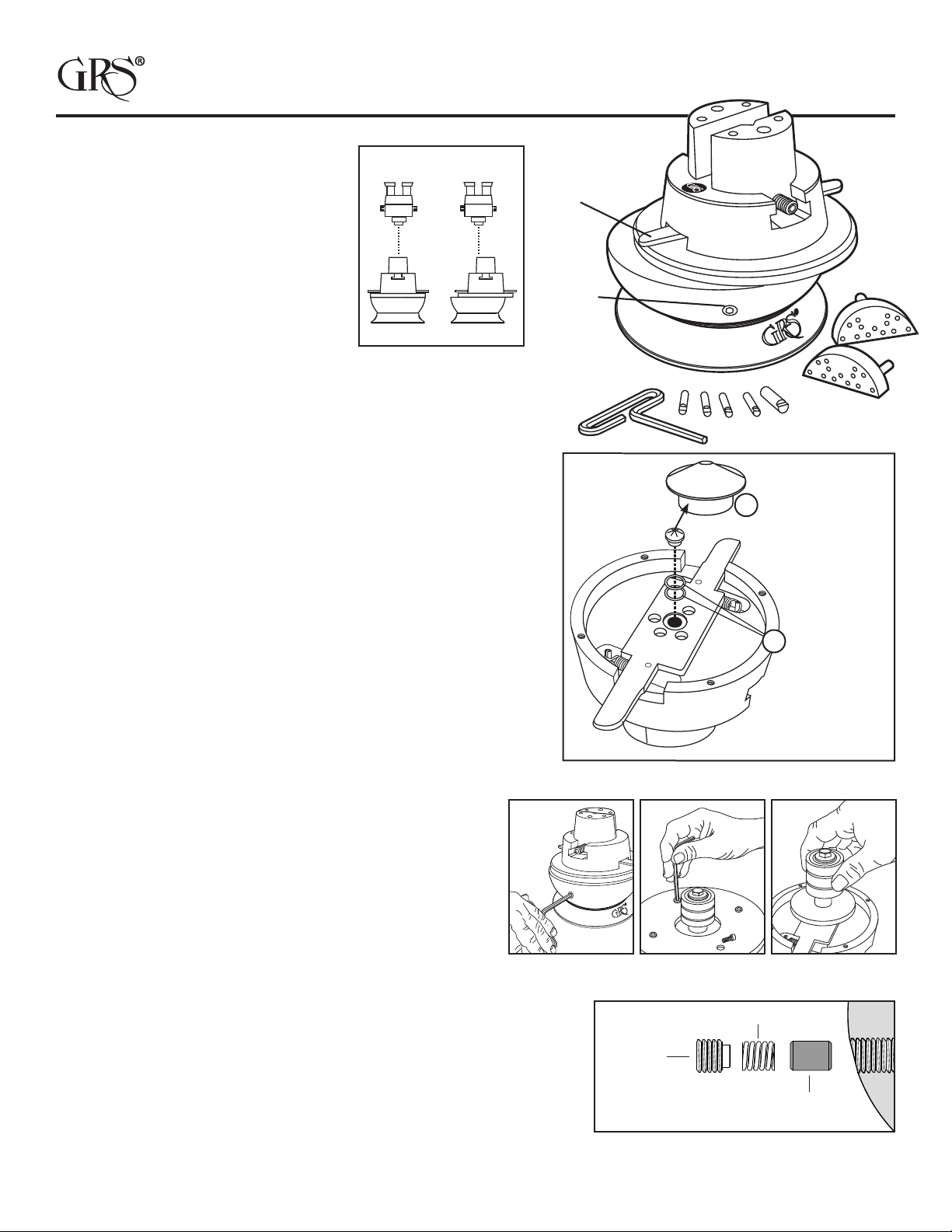

Rotational Lock Replacement

The LOCK or DRAG PIN is subject to wear and may need replacement

after extended use. Simply remove the ball swivel tension screw with the

hex wrench. The Spring and Lock Pin should follow (FIG. 7). If not, turn

the ball until they fall out. Replace the Lock Pin (#003-046), Spring, and

Tension Screw.

Thread Pin Replacement Kit • #003-627

Includes Jaw Screw, Left and Right Thread Pins, O-Rings, and Tube

of Synthetic Grease.

Lock Pin

#003-046

Tension

Screw

Spring

FIG. 7