5

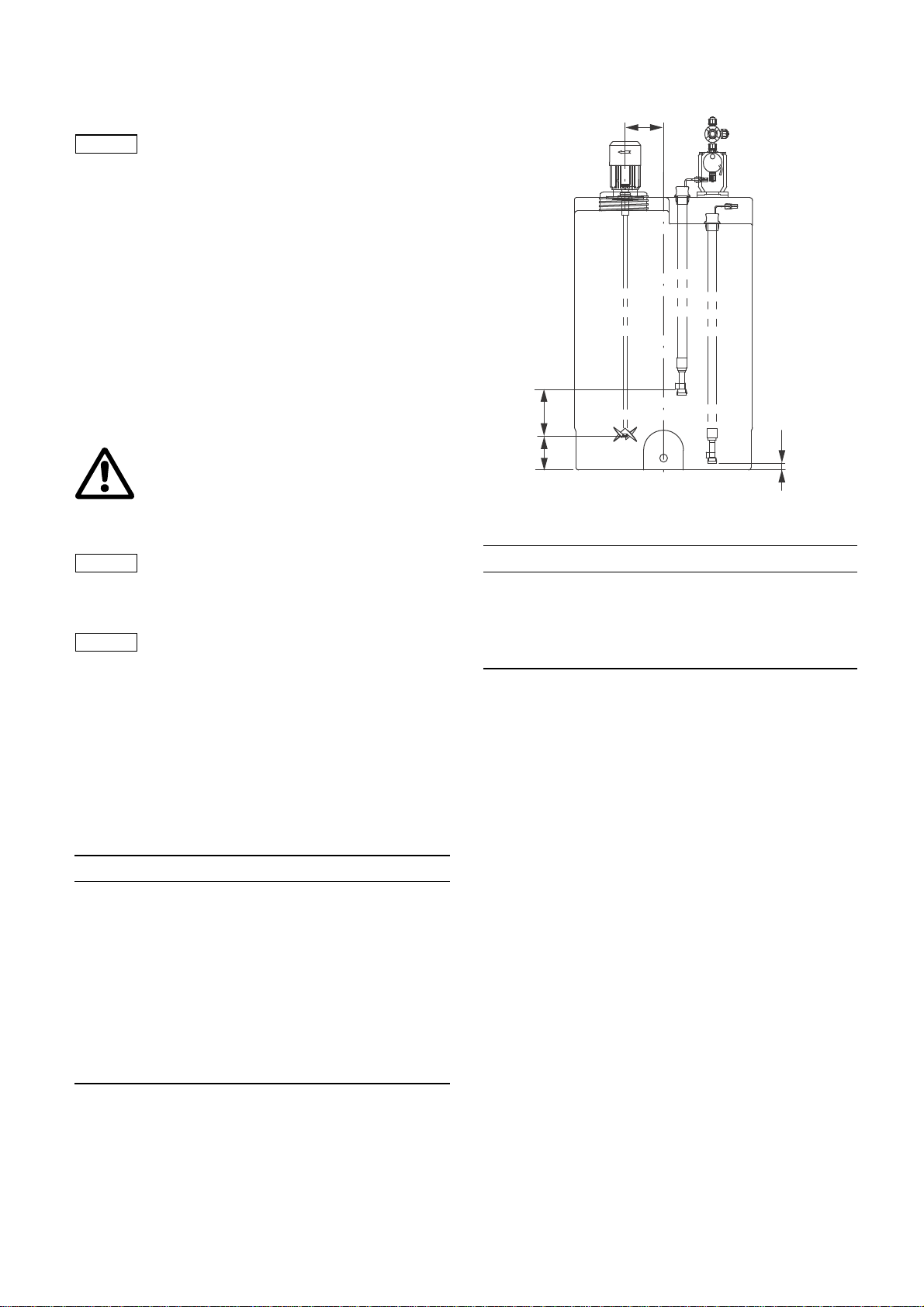

4. Intended purpose

Agitators from Grundfos Alldos, series 509, are intended for the

mixing and loosening of dosing media as described in these

instructions.

4.1 Guarantee

In line with our general conditions of sale and delivery,

a guarantee claim can only be recognised if:

• the agitator was only used as described in

the corresponding instructions.

• the agitator has been neither dismantled

nor incorrectly operated.

• repairs have only been carried out by authorised

and qualified personnel.

• only genuine spare parts have been used for repairs.

5. Safety

These instructions contain general information which should be

observed when installing, operating and maintaining the agitator.

These instructions must therefore be read with care by

technicians and appropriately trained specialists/operators before

installation and commissioning and must always be available at

the installation site.

It is not only the general safety notices described in this "Safety"

section that must be observed, but all specific safety notices that

are provided in the other sections too.

5.1 Identification of safety notices in this manual

If the safety notices or other information provided in these

instructions are not observed, this may result in injury and the

agitator may be damaged. Safety notices and other information

are identified by the following symbols:

Information on the agitator must be clearly legible at all times.

5.2 Qualification and training of staff

The staff responsible for operation, maintenance, inspection and

installation must be suitably qualified for this work. Areas of

responsibility, levels of responsibility and staff supervision must

be precisely defined by the person responsible for operations.

If staff do not have the necessary knowledge, they should be

trained and instructed accordingly. The person responsible for

operations is in charge of ensuring that the staff understand the

content of these instructions.

5.3 Risks when safety notices are not observed

Non-observance of the safety notices may have dangerous

consequences for staff, the environment and the pump. Non-

observance of the safety notices may lead to the loss of any

claims for damages.

Non-observance of the safety notices may lead to the following

risks:

• failure of important functions of the agitator / system

• failure of prescribed methods for maintenance

• personal injury caused by electrical, mechanical and chemical

influences

• environmental damage due to media hazardous to health

escaping.

5.4 Safety-conscious working

The safety notices in these instructions should be observed in the

same way as statutory health and safety at work guidelines and

the operating and safety notices provided by the person

responsible for operations.

5.5 Safety notices for the person responsible for

operations / user

Dangerous hot or cold parts on the agitator must be protected to

avoid accidental contact.

Hazards caused by electrical energy must be prevented (for more

details, please refer to the relevant regulations, for example those

of the VDE and the local power supply company).

5.6 Safety notices for maintenance, inspection and

installation work

The person responsible for operations must ensure that all

installation, maintenance and inspection work is undertaken by

authorised specialists who are appropriately trained by reading

these instructions.

All work on the agitator may only be carried out with the device

switched off.

All safety and protection equipment must be put back into

operation as soon as work is complete.

5.7 Unauthorised modification and impermissible

spare parts

Modifications or changes to the agitator are only permitted with

the consent of the manufacturer. Genuine spare parts and

accessories approved by the manufacturer are safe to use.

Liability cannot be assumed if spare parts which are not genuine

are used.

5.8 Incorrect operation

The operating safety of the agitator supplied is only ensured if it is

used in compliance with section 6.2 Technical data. The specified

limit values should on no account be exceeded.

No other applications are approved or permitted.

Grundfos Alldos is not liable for damage

resulting from incorrect use.

Warning

Failure to observe these safety notices may

result in injury.

Failure to observe these safety notices may

result in malfunction and damage to property.

Information or instructions intended to simplify

use and ensure safe operation.

Warning

Electrical connections may only be established

by trained staff.

Do not open the agitator under any

circumstances.

Repairs may only be undertaken by authorised

and qualified staff.

Warning

When dosing dangerous media, observe the

corresponding safety precautions.

Wear protective clothing (gloves and goggles) if

required.