English (GB)

10

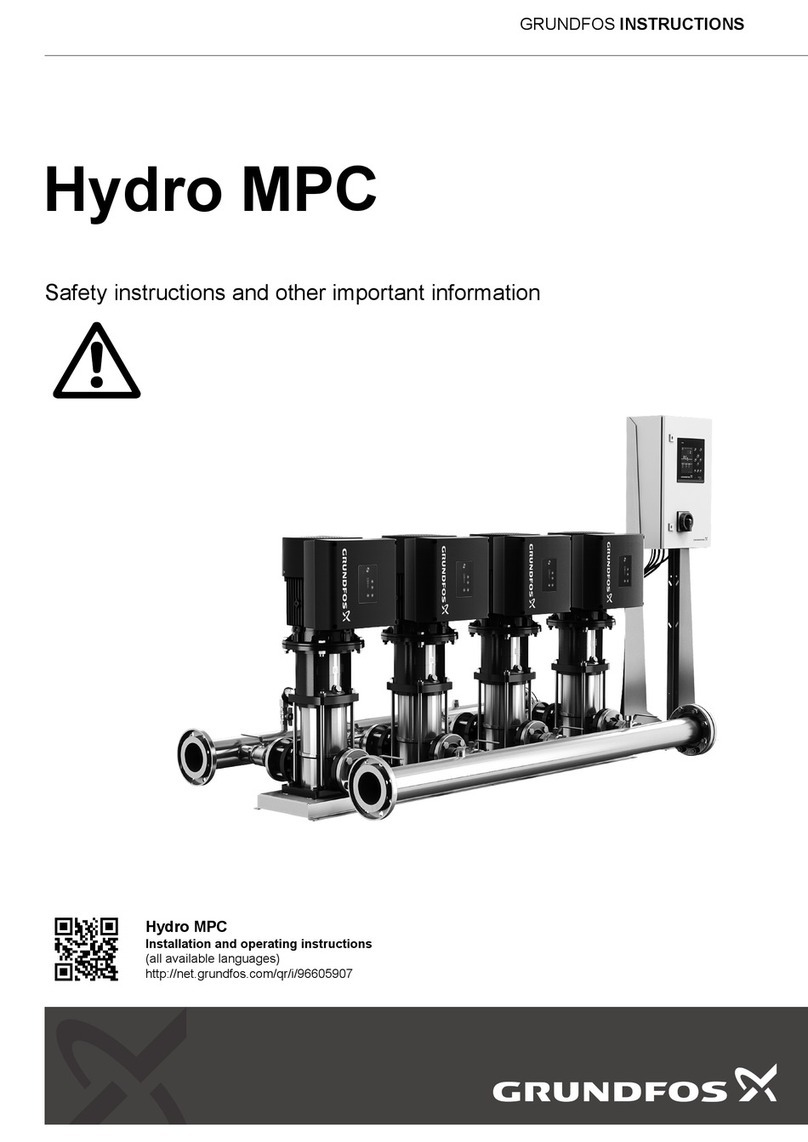

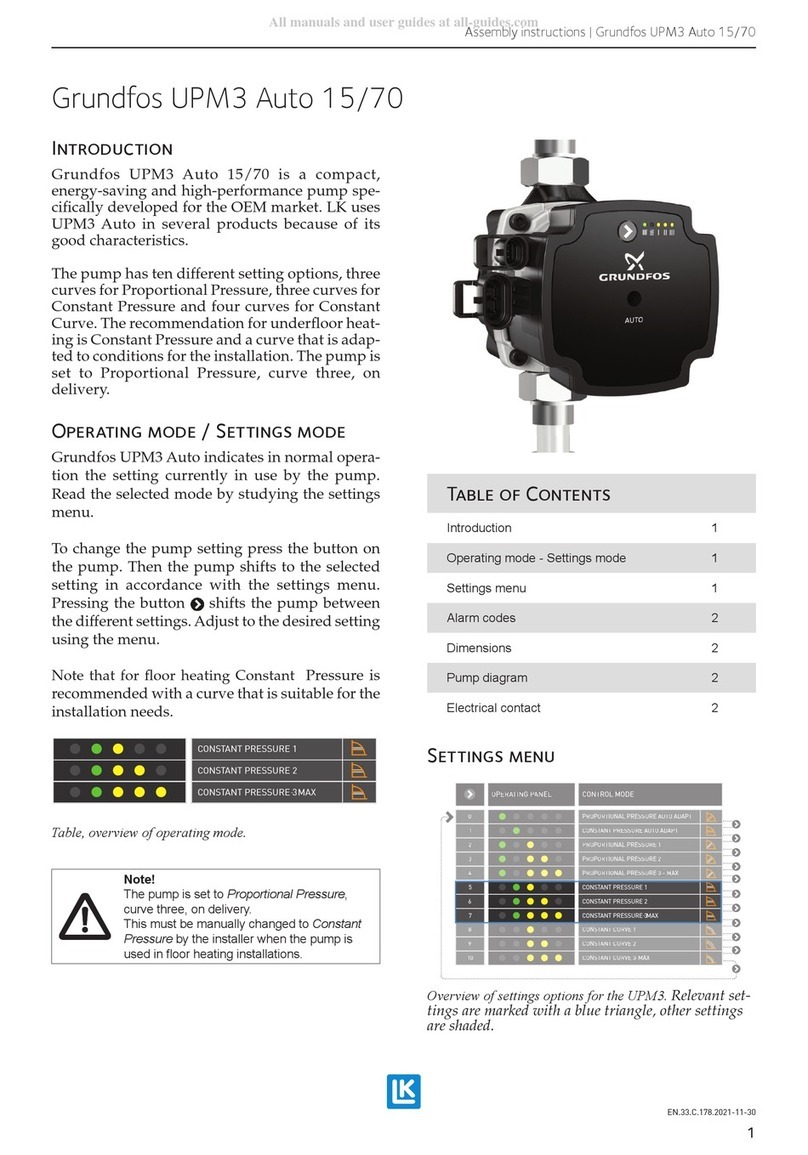

Permanent, horizontal installation in a pump room

Fasten the pump to the suction and discharge pipes by means of

flange connections. See fig. 8.

Fig. 8 Dry, horizontal installation with base stand and bracket

8.2 Permanent, vertical, submerged installation in a pit

Pumps for permanent, vertical installation in a pit can be installed

on a stationary auto coupling and operated completely or partially

submerged in the pumped liquid.

Proceed as follows:

1. Drill mounting holes for the guide-rail bracket on the inside of

the pit and fasten the guide-rail bracket provisionally with two

screws.

2. Place the auto-coupling base unit on the bottom of the pit.

Use a plumb line to establish the correct positioning. Fasten

the auto coupling with expansion bolts. If the bottom of the pit

is uneven, the auto-coupling base unit must be supported so

that it is level when being fastened.

3. Assemble the discharge pipe in accordance with the generally

accepted procedures and without exposing the pipe to

distortion or tension.

4. Place the guide rails on the auto-coupling base unit and adjust

the length of the rails accurately to the guide-rail bracket at

the top of the pit.

5. Unscrew the provisionally fastened guide-rail bracket. Insert

the expansion dowels into the holes. Fasten the guide-rail

bracket on the inside of the pit. Tighten the bolts in the

expansion dowels.

6. Clean out debris from the pit before lowering the pump into

the pit.

7. Fit the guide claw to the pump.

8. Slide the guide claw of the pump between the guide rails and

lower the pump into the pit by means of a chain secured to the

lifting bracket of the pump. When the pump reaches the

auto-coupling base unit, the pump will automatically connect

tightly.

9. Hang up the end of the chain on a suitable hook at the top of

the pit and in such a way that the chain cannot come into

contact with the pump housing.

10. Adjust the length of the motor cable by coiling it up on a relief

fitting to ensure that the cable is not damaged during

operation. Fasten the relief fitting to a suitable hook at the top

of the pit. Make sure that the cables are not sharply bent or

pinched.

11. Connect the motor cable and the control cable, if any.

8.2.1 Size of anchor bolts in bottom or plinth

8.3 Permanent, vertical/horizontal, dry installation in a

pump room

Pumps in dry installation are installed permanently in a pump

room.

The pump motor is enclosed in a watertight cooling jacket and will

not be damaged if the installation site is flooded with water.

Proceed as follows:

1. Mark and drill mounting holes in the concrete floor/concrete

foundation.

2. Fit the bracket or base stand to the pump.

3. Fasten the pump with expansion bolts.

4. Check that the pump is vertical/horizontal.

In order to facilitate service on the pump, we recommend that you

use isolating valves on either side of the pump.

5. Fit the suction and discharge pipes and isolating valves, if

used, and ensure that the pump is not stressed by the

pipework.

6. Adjust the length of the motor cable by coiling it up on a relief

fitting to ensure that the cable is not damaged during

operation. Fasten the relief fitting to a suitable hook. Make

sure that the cables are not sharply bent or pinched.

7. Connect the motor cable and the control cable, if any.

Installation type H

TM05 2539 0212

Make sure that the pipework is installed without

the use of undue force. No loads from the

pipework weight must be carried by the pump.

We recommend that you use loose flanges to

ease the installation and to avoid pipe tension at

the flanges.

Do not use elastic elements or bellows in the

pipework; these elements should never be used

as a means to align the pipework.

In some installations, a plinth is required beneath

the auto coupling to ensure correct installation of

the pump. This should be considered during the

design of the installation.

The guide rails must not have any axial play as

this would cause noise during pump operation.

The free end of the cable must not be submerged,

as water may penetrate through the cable into the

motor.

Auto-coupling

base unit Anchor bolts

Pull-out strength,

single bolt

[kN]

DN 80/100 4 x M16 10.0 kN

DN 100 4 x M16 10.0 kN

DN 150 4 x M16 10.0 kN

DN 200 4 x M24 10.0 kN

DN 250 4 x M24 10.0 kN

DN 300 4 x M24 12.0 kN

The strengths given above are without safety

factor. Required safety factor may depend on the

materials and the method used for anchoring.