Table of Contents

PNEG-2116 Bucket Elevator 3

Contents

Chapter 1 Introduction ..........................................................................................................................................4

General Information .............................................................................................................................. 4

General Safety Statements ................................................................................................................... 4

Replacement Parts ................................................................................................................................ 4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Cautionary Symbols Definitions ............................................................................................................ 6

Safety Cautions ..................................................................................................................................... 7

Safety Sign-Off Sheet ......................................................................................................................... 11

Chapter 3 Decals ..................................................................................................................................................12

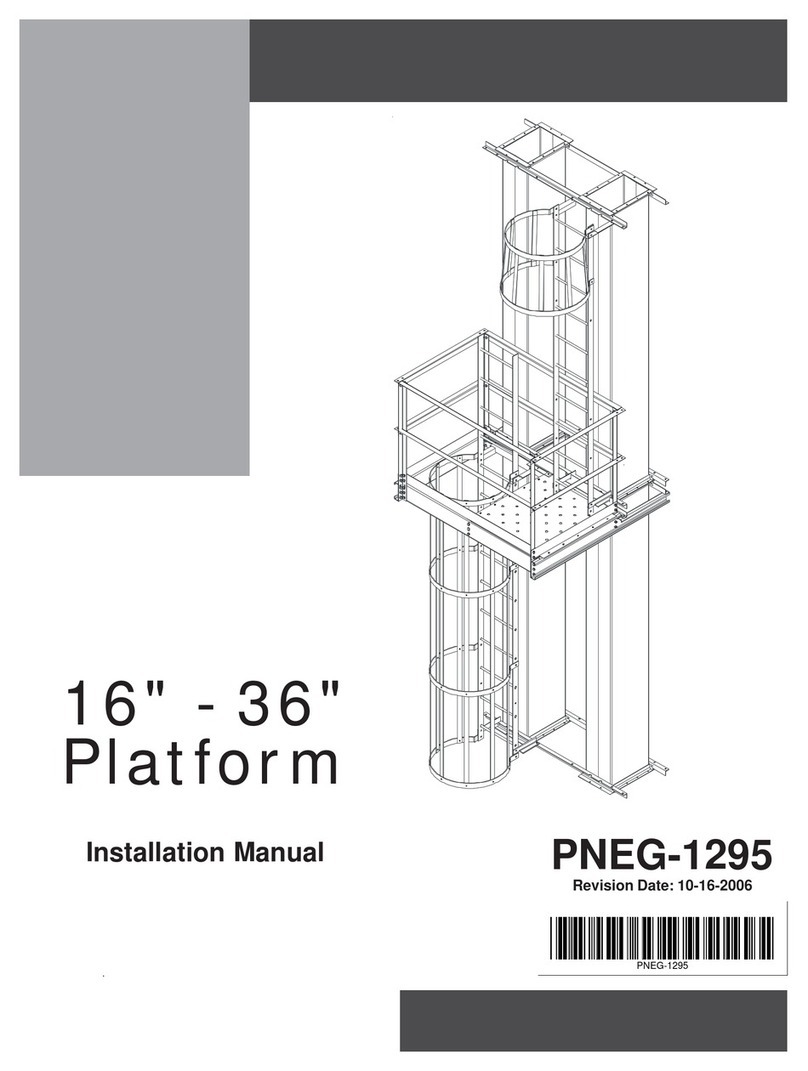

Chapter 4 Installation ..........................................................................................................................................16

Receiving Inspection ........................................................................................................................... 16

Pre-Installation Preparation ................................................................................................................. 16

Elevator Foundation ............................................................................................................................ 16

Elevator Guying or Bracing ................................................................................................................. 17

Elevator Intake .................................................................................................................................... 18

Elevator Discharge .............................................................................................................................. 19

Positioning Trunk Sections for Ladder ................................................................................................ 19

Elevator Belt Selection ........................................................................................................................ 19

Elevator Erection (Assembly) .............................................................................................................. 20

Ladder Assembly with Safety Cages .................................................................................................. 23

Typical Small Head Service Platform Assembly ................................................................................. 25

Typical Large Head Service Platform Assembly ................................................................................. 25

Typical Head Service Hatch Assembly ............................................................................................... 26

Belt and Bucket Installation ................................................................................................................. 27

Belt Splicing ........................................................................................................................................ 32

Hood Installation ................................................................................................................................. 34

Drive Installation .................................................................................................................................. 34

Chapter 5 Operation ............................................................................................................................................35

Initial Belt Tracking .............................................................................................................................. 35

Rubber Throat Slide Adjustment ......................................................................................................... 37

In-Service Belt Tension ....................................................................................................................... 38

Elevator Bucket Filling ......................................................................................................................... 39

Chapter 6 Maintenance and Repair ....................................................................................................................41

General Maintenance .......................................................................................................................... 41

General Housekeeping and Periodic Inspection ................................................................................. 41

Lubrication ........................................................................................................................................... 42

Adjustment and Repair Procedure ...................................................................................................... 43

Chapter 7 Warranty ..............................................................................................................................................45