Dangers of High Voltages and Large Current

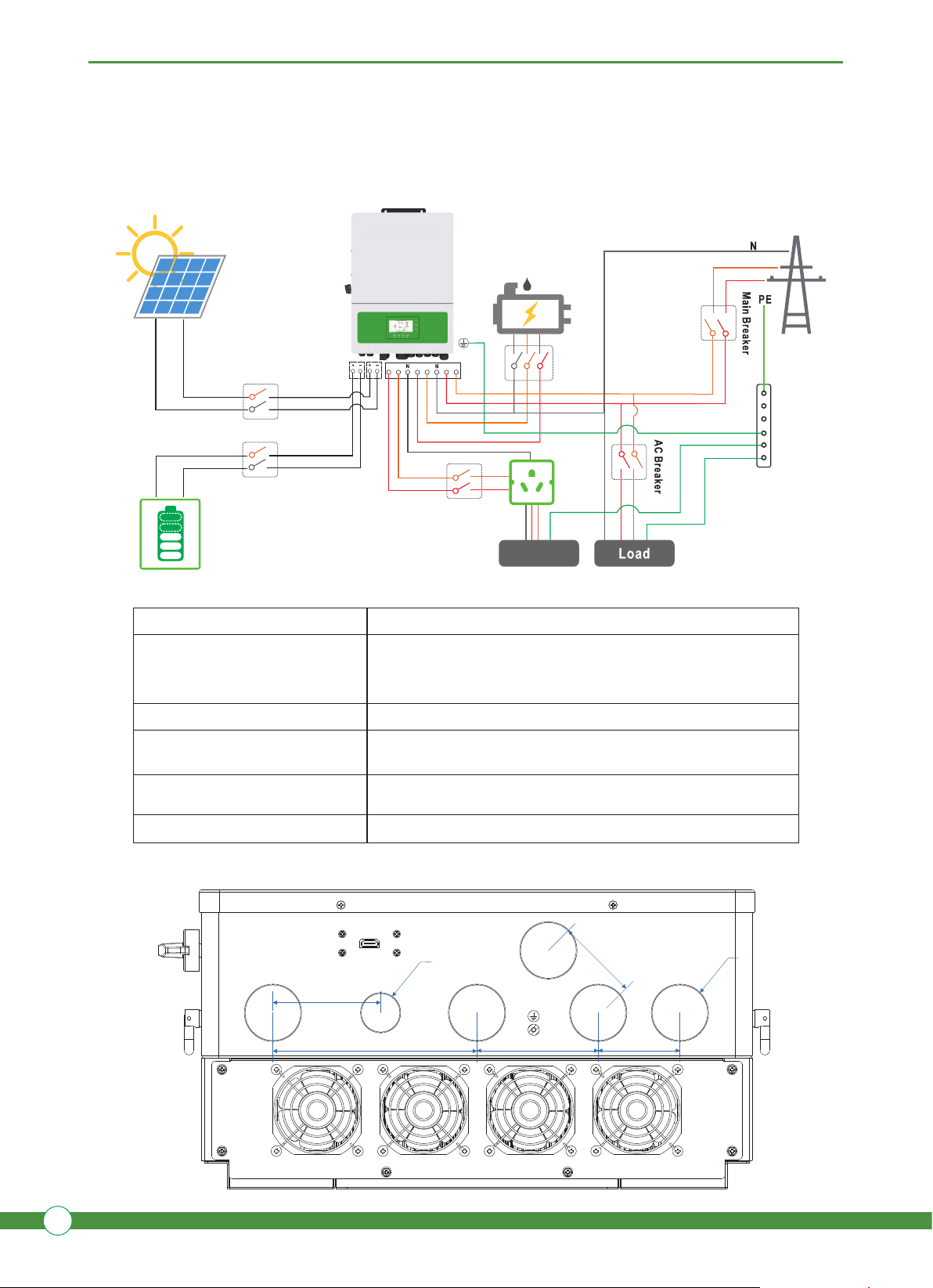

Beware of high PV voltage. Please turn-off the DC switch of PV Panel output before and during

the installation to avoid electric shock.

Beware of high grid voltage. Please turn-off the AC switch of grid connection before and during

the installation to avoid electric shock.

Do not operate the inverter when it's working, only the LCD and buttons can be touched in

limited cases by qualified personnel, other parts of the inverter can be touched when the

inverter is under a safe state (e.g. fully shut-down).

Inspect the connections are good between inverter and PV, battery and grid during installation

to prevent damages or injuries caused by bad connections.

Inspect relevant existed wiring on-site of the installation is under good condition before

installation, operation or maintenance.

Make sure the inverter is well grounding, an operator should make sure himself is good

protected by reasonable and professional insulation measurements (e.g. personal protective

equipment (PPE)).

Do not connect or disconnect any connections (PV, battery, grid, communication etc.) of the

inverter when it's working.

Beware of large current of the battery output. Please turn-off the battery module before and

during the installation to avoid electric shock.

Do not open the inverter when it's working to avoid electric shock and damages from live

voltage and current from the system.

1. Safety

1.1 Safety Instruction

General Safety Instructions

The inverter has been designed and tested strictly according to international safety regulations. Read all safety

instructions carefully prior to any work and observe them at all times when working on or with the inverter. The

operator must be qualified personnel and the installation must be capable with relevant national or international

standards or regulations.

Incorrect operation or work may cause:

- injury or death to the operator or a third party

- damage to the inverter and other properties belonging to the operator or a third party.

There are many safety issues need to be carefully notified before, during and after the installation, and also in

future operation and maintenance, following is important safety notifications to operator, owner and user of

this product in appropriate usage.

Important Safety Notifications

01