GENERAL INFORMATION

GUARDAIR CORPORATION’S AirSpade Series 2000 is a compressed air-

powered tool used for excavation of a wide variety of soils. AirSpade Series 2000

consists of an ergonomic pistol grip style handle, an insulated fiberglass barrel,

and a patented supersonic nozzle. Typically powered by a portable tow-behind

air compressor, the AirSpade Series 2000 provides a safe, powerful and

efficient method of uncovering underground electric lines, pipes, and tree roots

without harm. Capable of excavation where a shovel or backhoe cannot be used,

AirSpade can be equipped with multiple nozzle sizes and a variety of extension

lengths for optimum job performance.

The heart of the AirSpade is the patented supersonic nozzle which produces a

focused “laser-like” jet of air moving at approximately 1,200 mph (1,900 km/hr),

or nearly twice the speed of sound. This supersonic air-jet penetrates voids in

the soil and expands rapidly, therefore fracturing the soil. Unlike the hard cutting

edges of shovels, picks, blades, or buckets, the air-jet is harmless to non-porous

items such as tree roots, buried pipes, or cables. Excavating with AirSpade is

much easier and many times faster than hand excavation.

The AirSpade supersonic air-jet outperforms “homemade tools” featuring a pipe

nipple or a crimped orifice. Air flow from these tools expands to atmosphere in

an unfocused, complex manner while the supersonic air jet delivers significantly

more kinetic energy and more focused momentum. In practical terms the

AirSpade does more work by moving more material, and harder material, in a

shorter period of time.

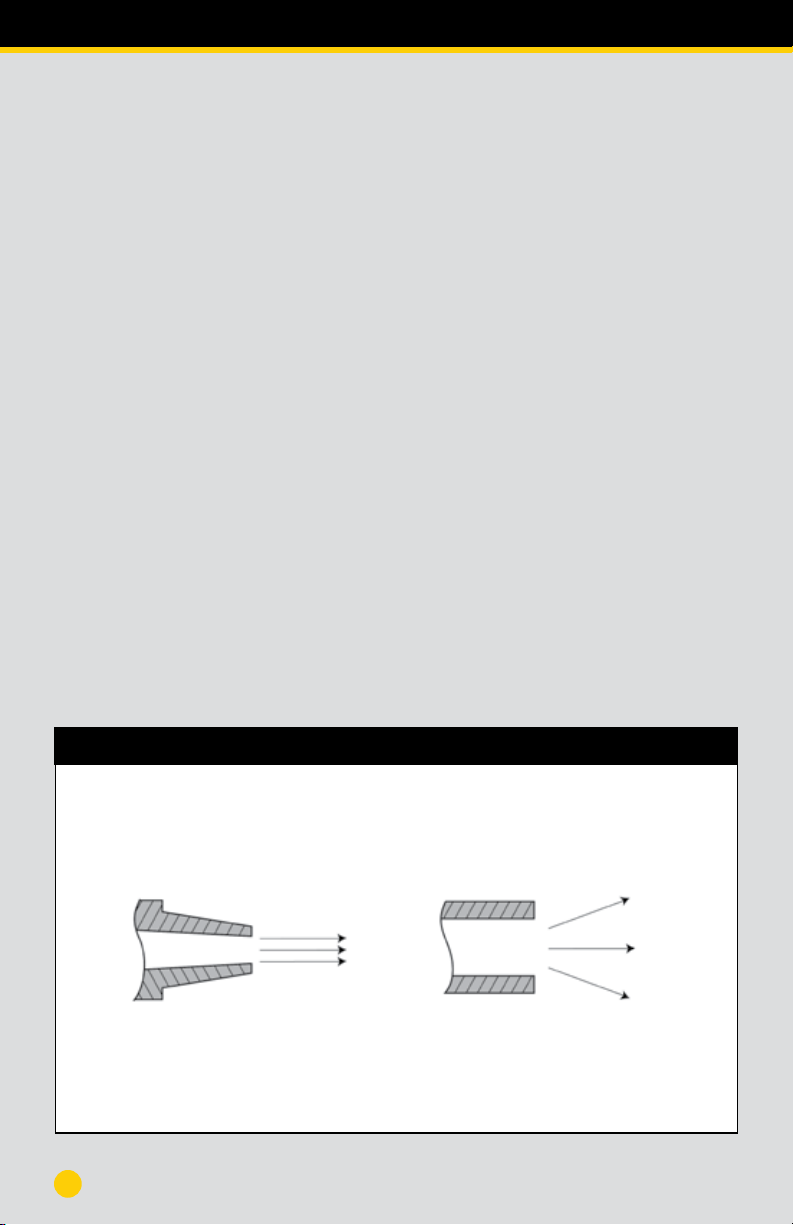

(Fig.A)

FOCUSED AIR FLOW FROM

AirSpade SUPERSONIC NOZZLE

(Fig.B)

UNFOCUSED AIR FLOW FROM

IMPROPERLY DESIGNED NOZZLE

AirSpade’s patented supersonic nozzle turns compressed air into a high-speed, laser-like jet moving at twice

the speed of sound – 1,200 mph. All of the energy and momentum of air moving at approximately Mach 2

is focused into the soil, dislodging it in a fraction of a second. (Fig.A) The result is faster, safer, and more

efficient soil excavation.

Air exiting from an improperly designed nozzle diffuses outward 3 to 4 times wider than the air-jet from the

patented AirSpade supersonic nozzle. (Fig.B).

4

AIRSPADE PATENTED SUPERSONIC NOZZLE