GISS 2000 Operating Manual

2

Inhaltsverzeichnis

Contents

Introduction .........................................................................................................................................3

Symbols and pictographs ..................................................................................................................3

1.) Safety ..............................................................................................................................................4

1.1 Danger potential of the equipment ......................................................................................4

1.2 Safety notes............................................................................................................................4

1.3 Correct application.................................................................................................................5

1.4 Work area requirements........................................................................................................5

1.5 Authorised operators.............................................................................................................6

2.) Shipping and packaging................................................................................................................6

2.1 Delivery ...................................................................................................................................6

2.2 Unpacking...............................................................................................................................6

3.) Decription of equipment ...............................................................................................................7

3.1 Functional description ...........................................................................................................7

3.2 Types.......................................................................................................................................7

3.3 Dynamic output regulator ....................................................................................................8

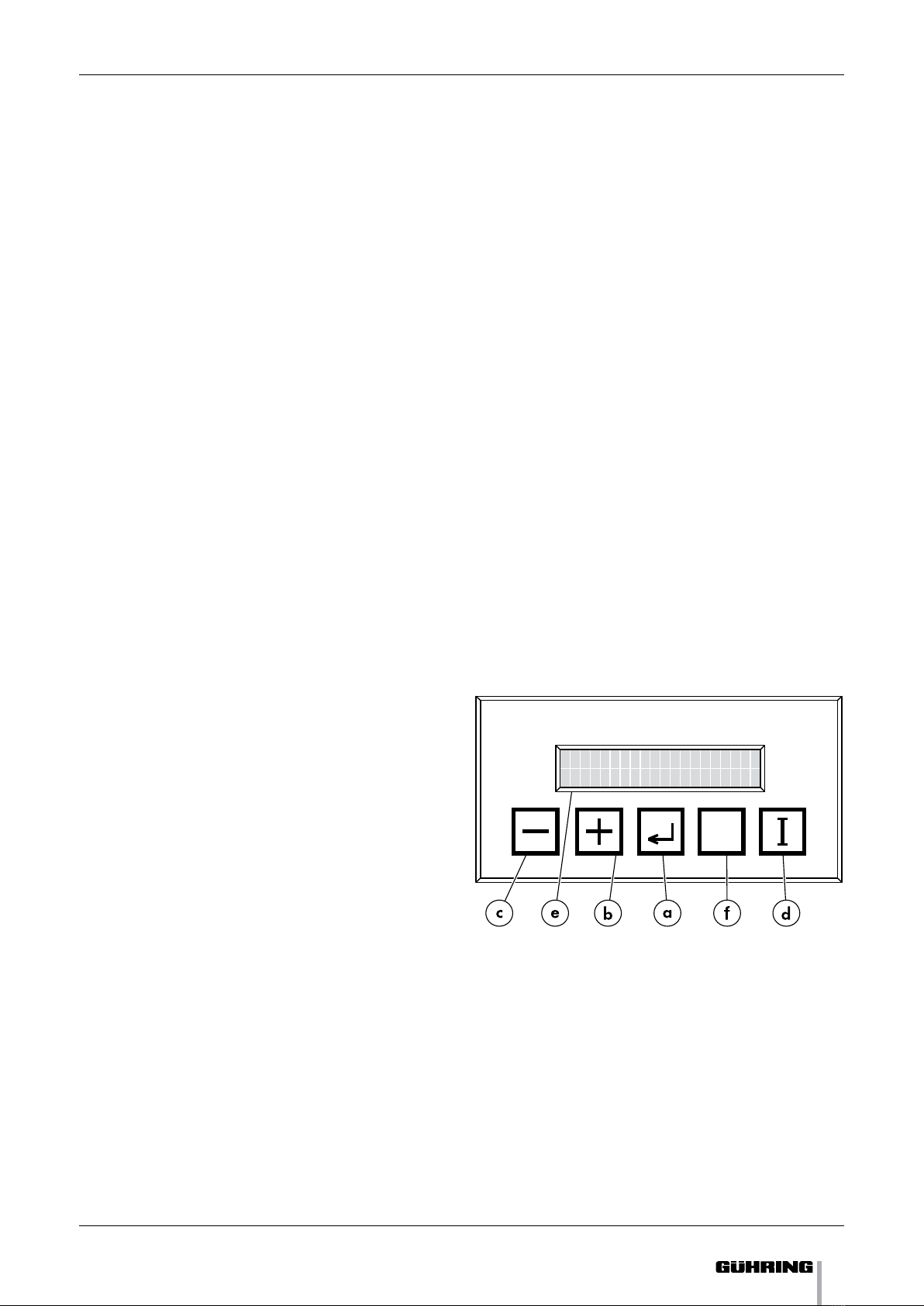

3.4 Key pad and display...............................................................................................................8

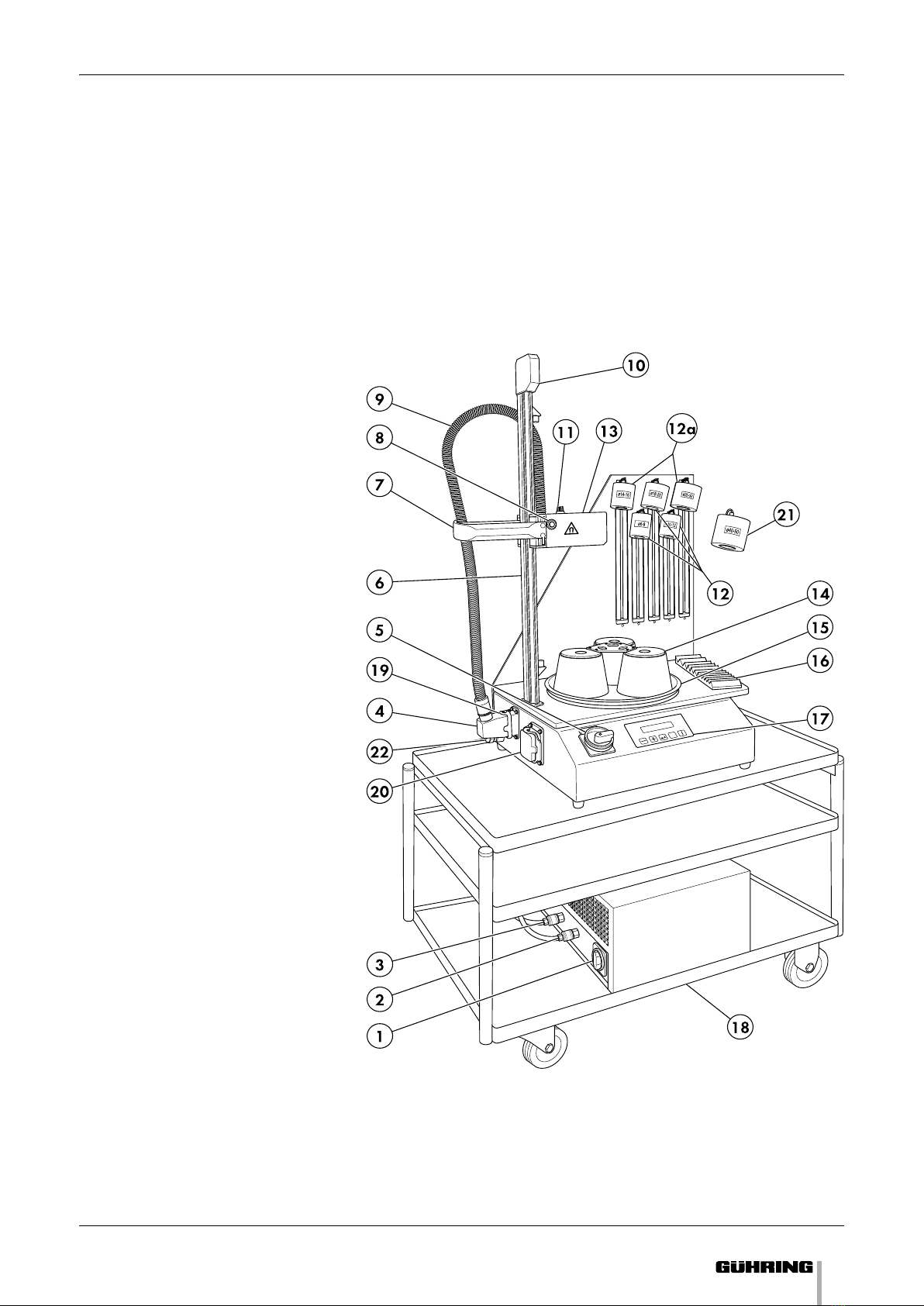

3.5 System summary...................................................................................................................9

4.) Commissioning and operation ...................................................................................................10

4.1 Electrical connection...........................................................................................................10

4.1.1 GISS 2000 .......................................................................................................................10

4.1.2 SPEED-COOLER ............................................................................................................. 11

4.2 Installation and assembly ...................................................................................................12

4.2.1 GISS 2000.......................................................................................................................12

4.2.2 SPEED-COOLER (optional) ...........................................................................................14

4.2.3 Inserting the adaptors...................................................................................................15

4.2.4 Speed Cooler Manager.................................................................................................16

4.3 Switching-on the equipment ..............................................................................................17

4.4 Menu guide..........................................................................................................................17

4.4.1 Shrink fit menu ............................................................................................................19

4.4.2 Setting the heating time .............................................................................................20

4.4.3 Setting the language ..................................................................................................21

4.4.4 Setting the dimensional system ...............................................................................22

4.4.5 Selecting the operating type .....................................................................................22

4.4.6 Retrieving company settings .....................................................................................23

4.5 Operating process ...............................................................................................................25

4.5.1 Suitable shrink fit chucks ............................................................................................25

4.5.2 Preparing the shrink fit chucks and tools...................................................................25

4.5.3 Heating the shrink fit chuck.........................................................................................26

4.5.4 Cooling the shrink fit chuck .........................................................................................29

4.6 Switching-off the equipment .............................................................................................30

4.7 GISS 2000 Trouble-shooting ...............................................................................................31

4.7.1 Error messages .............................................................................................................31

4.7.2 Other malfunctions.......................................................................................................31

4.8 SPEED-COOLER Troubleshooting ......................................................................................33

4.8.1 Venting the cooling system .........................................................................................34

4.8.2 Water pump not running .............................................................................................34

4.8.3 Condensation on dissipator ........................................................................................35

4.9 Important notes regarding the shrink fitting process......................................................35

5.) Cleaning ........................................................................................................................................36

5.1 Speed Cooler ........................................................................................................................36

5.2 GISS 2000 shrink fit system ................................................................................................36

6.) Maintenance and repairs ............................................................................................................37

6.1 Maintenance .........................................................................................................................37

6.2 Replacing the GISS 2000 fine-wire fuse ............................................................................37

7.) Technical data...............................................................................................................................38

8.) Replacement parts.......................................................................................................................39