6

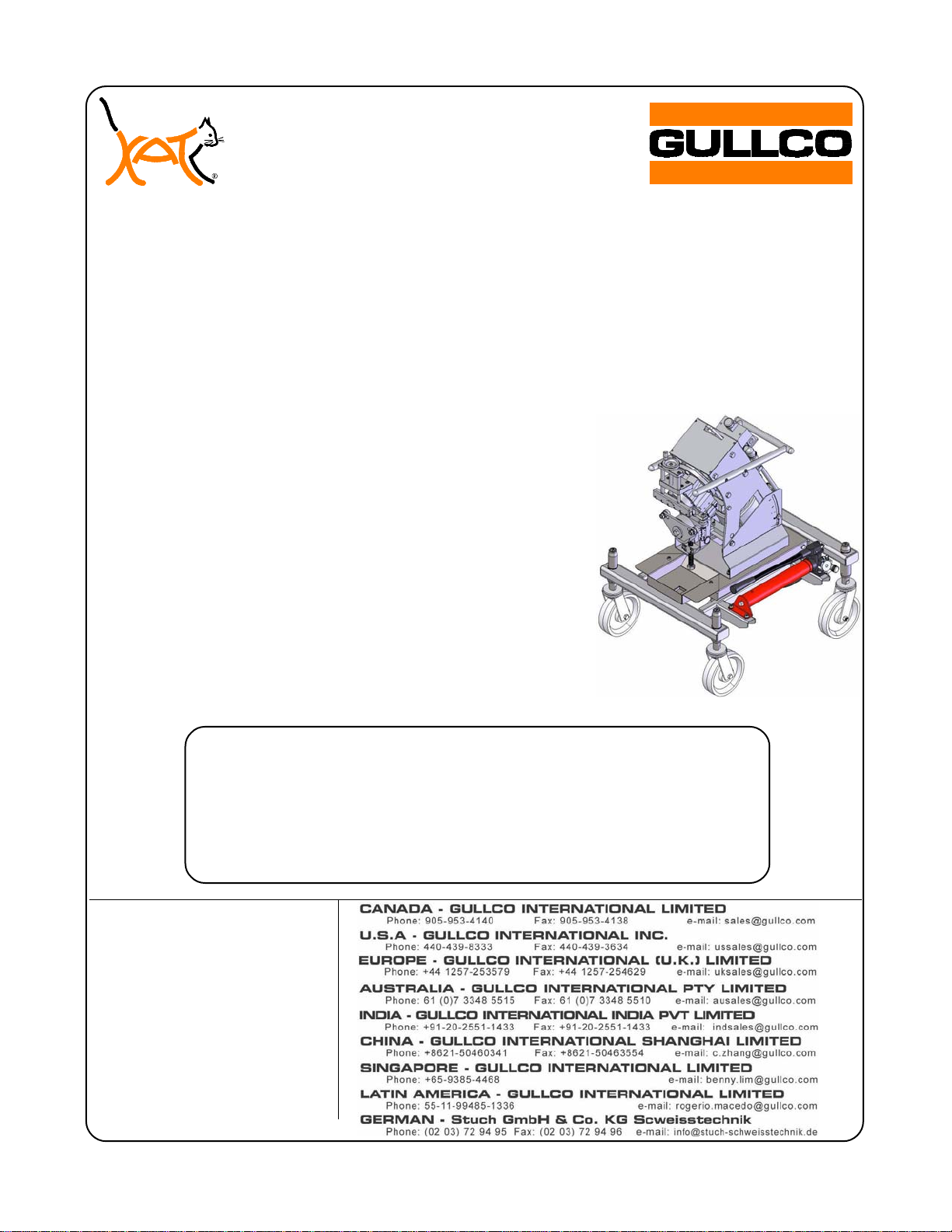

GENERAL DESCRIPTION

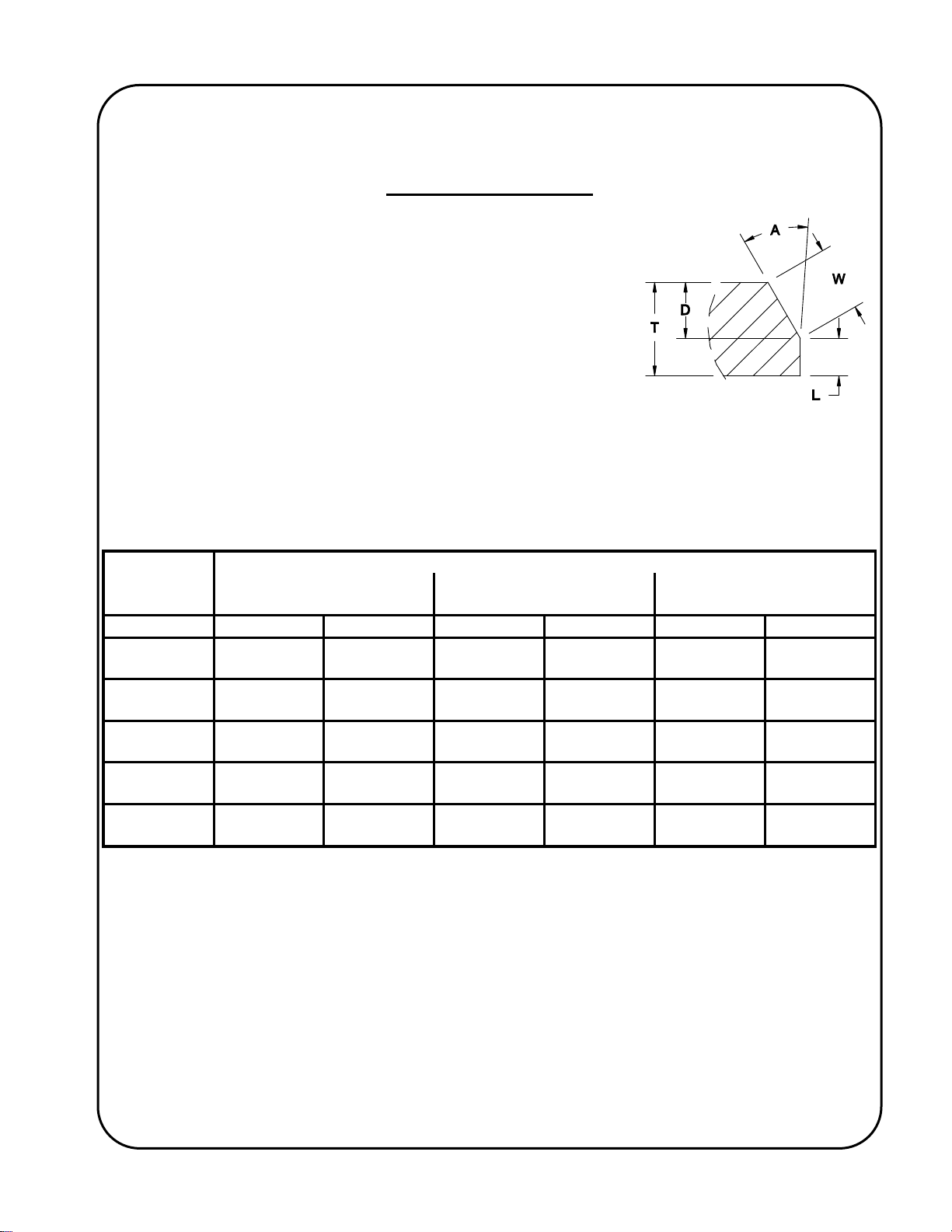

The Gullco KBM®-18 Portable Plate Edge Bevelling Machine is an electrically powered rotary shear.

It is used to bevel a wide variety of plate edges, usually for the purpose of a weld joint preparation.

It is designed for one-man operation and is capable of bevelling straight or circular plate sections at

a speed of approximately 13’ [4 m] per minute‡. It is capable of performing multi pass bevelling for

larger bevels that cannot be accomplished in a single pass. Easy adjustment is provided for

altering the depth and angle of bevel.

A push button, mechanical starter complete with short circuit, motor overload and also under-

voltage protection, is used to start and stop a 2 H.p., 3 phase motor, which in turn uses a heavy

duty industrial type gearbox assembly to drive a serrated cutter. This cutter provides the "Rotary

Shearing" as well the tractive effort to propel either the plate through the machine, or the machine

along the plate, depending on the application.

The KBM®-18 is capable of supporting its own weight while bevelling horizontal plate. The machine

is typically equipped with the optional spring loaded caster assembly that allows the machine to roll

along the floor, or runway, during the bevelling operation. The KBM®-18 machine can be used

without the optional undercarriage assembly to either; be used as a two-man unit in such cases

where it is impractical to use the caster assembly; or it could be bench mounted for applications

where the plate sections are small enough to manually feed through the cutter. The adjustable

bevelling head enables the bevelling of angles 22.5° through 55°.

The KBM®-18 is available for use with the following power supplies; 230, 460 and 575 V at 60 Hz.

and also 380 and 400/415 V at 50 Hz. The supply to be used must be specified at the time of

order. Gullco can also provide machines for use with supplies that are not listed above, please

consult Gullco for more details.

The KBM®-18 machine comes complete with a tool box which includes the bevel angle pins 22.5°,

30°, 37.5°, 45°, and 55°, cutter spacers, and all of the necessary wrenches and hexagonal keys that

are required to make adjustments to the machine.

Note: The machine is shipped from the factory with the 30° bevel angle pin in place.

INTENDED / FORESEEN USAGE

The Gullco KBM®-18 Portable Plate Edge Bevelling machine is used throughout the world to

automate and improve the quality and efficiency of the weld preparation required for manual,

semiautomatic and fully automatic welding operations.

It provides industry with a highly efficient, practical and truly portable method of producing straight

machined bevels on a wide variety of plate materials, including mild steel, stainless steel and

aluminum..... effectively meeting V, X or K weld joint preparation requirements.

Loss of production through operators suffering from skeletal, muscular and hearing loss injuries

normally associated with pneumatic and hand held milling type bevelling equipment is greatly

reduced and detrimental factors such as operator fatigue, or inconsistent workmanship are

eliminated. Required quality levels are consistently attained and productivity and profitability

increased.

‡Top speed can vary depending on variations of bevel depth, voltage and frequency.