TABLE OF CONTENTS

INSTALLATION INSTRUCTIONS

SILEAEH, MEDLEYEH, TRIOEH

R. 12/18

Pull Installation........................................................2

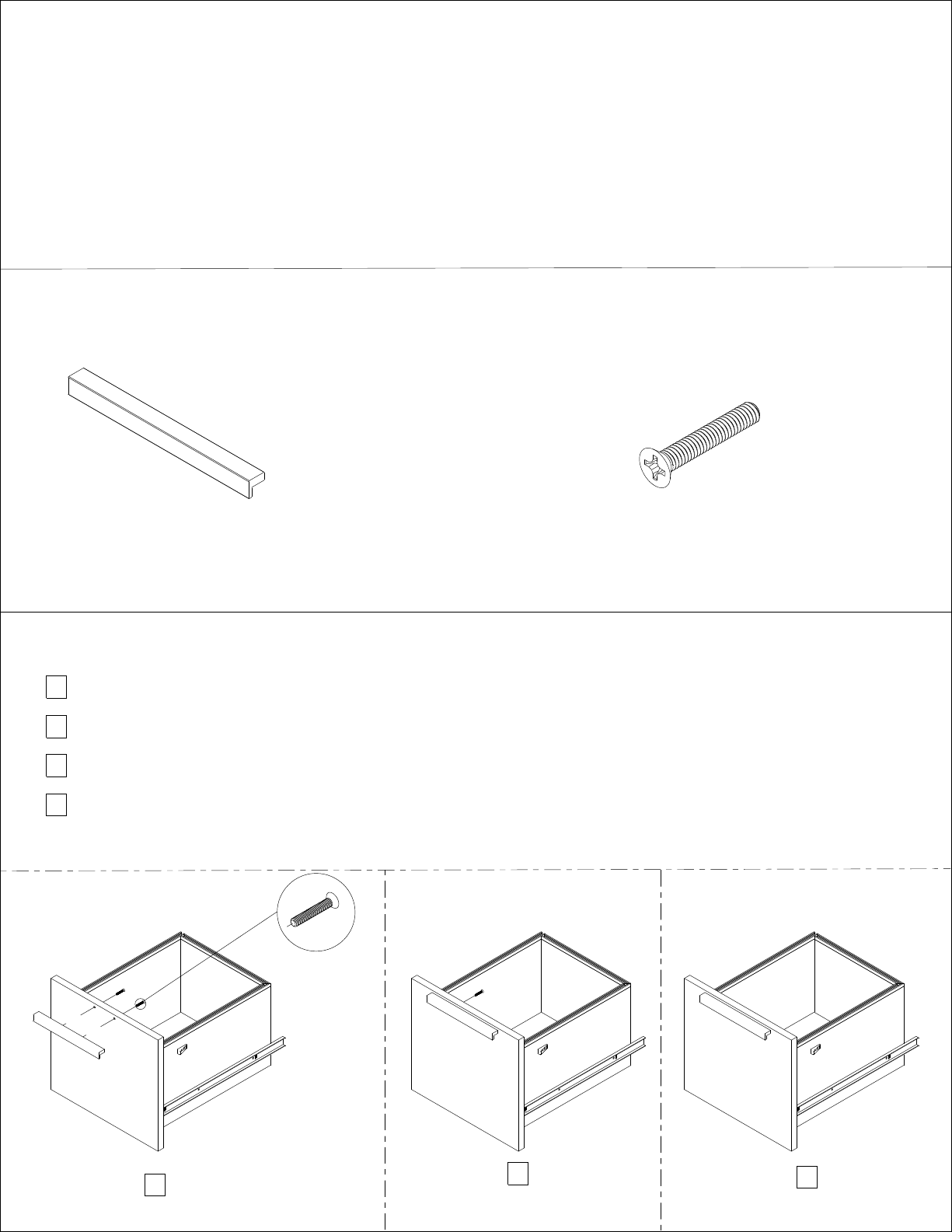

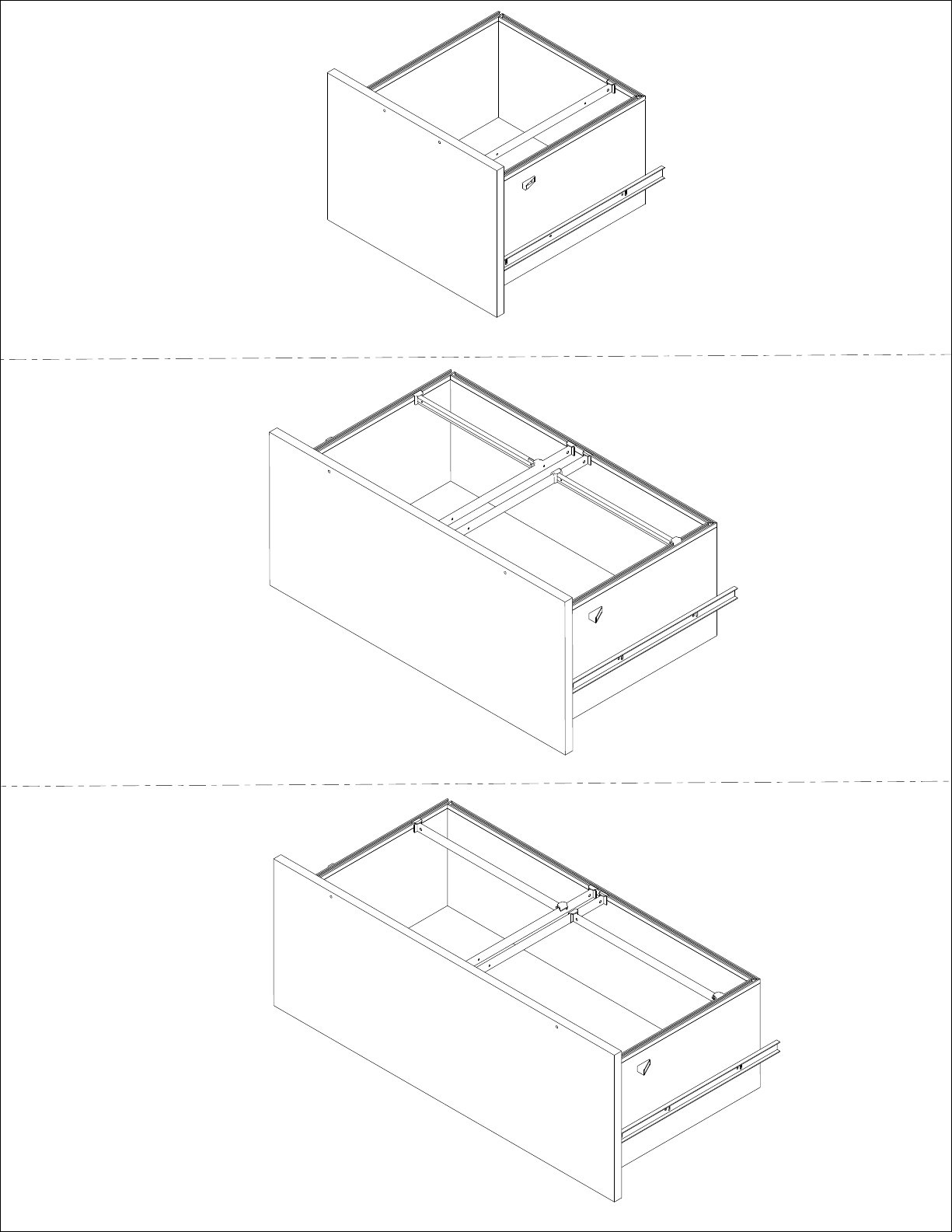

Drawer Removal & Installation.............................3

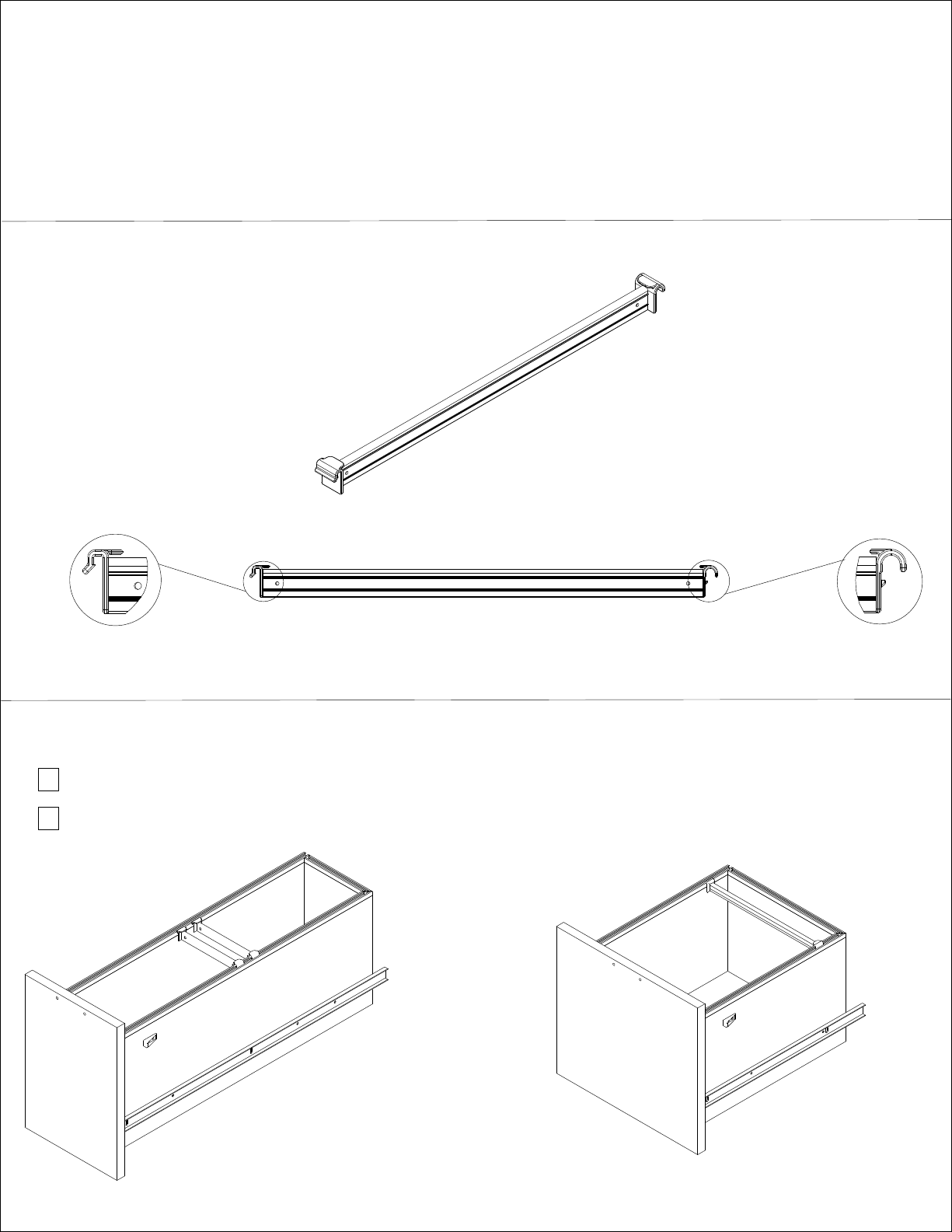

Pendaflex Bars..........................................................4

Digital Lock..............................................................6

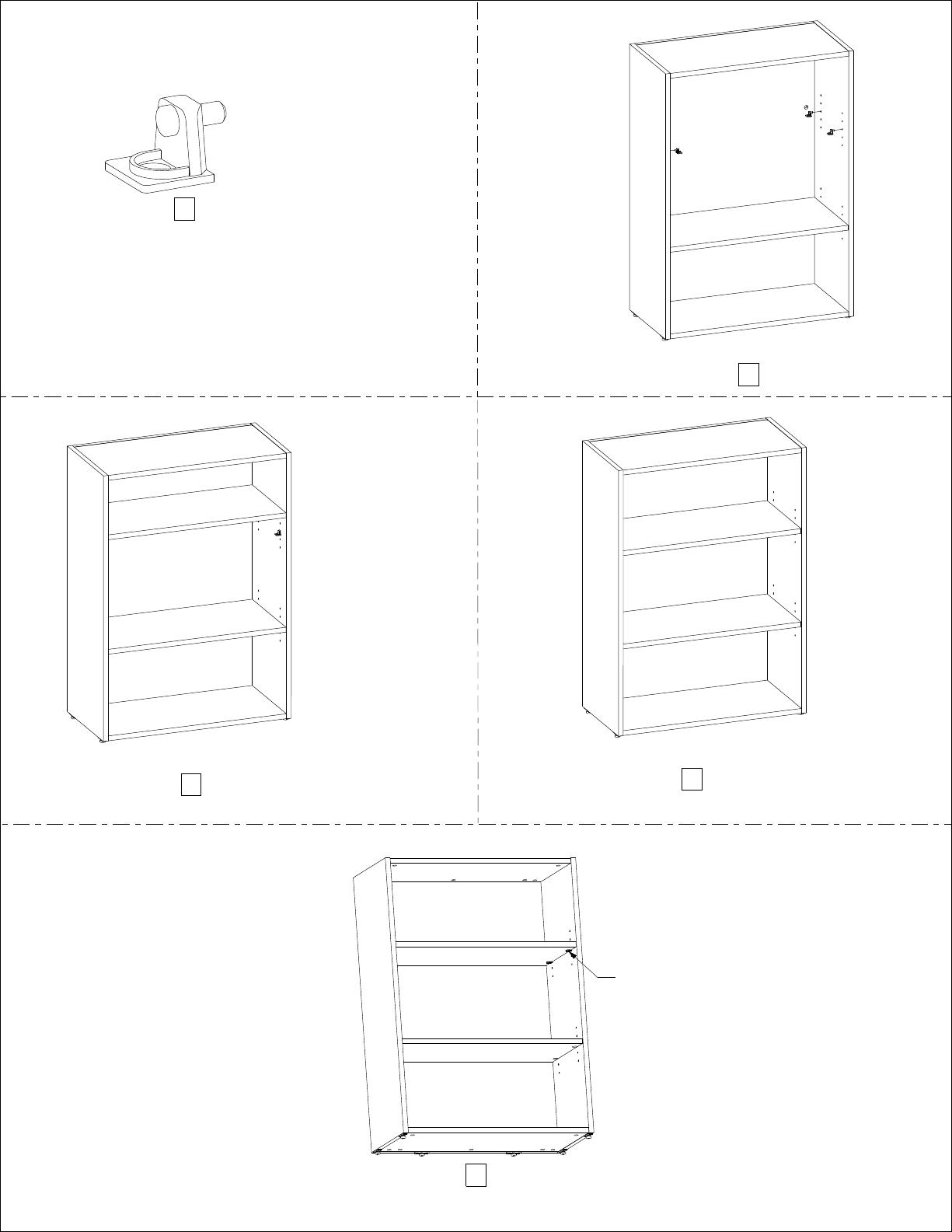

Adjustable Shelves...................................................7

Side Access Locker..................................................9

Floating Shelves.....................................................11

Mobile PED............................................................13

Trough & End Caps..............................................14

Hanging MOD Panels..........................................16

Worksurface Joining.............................................18

Wall Mount Worksurface....................................21

Wall Access Panel Build.......................................22

Modular Station Build..........................................24

Wall Mount Wall...................................................31

Wall Shelf...............................................................33

Magnetic Wall........................................................35

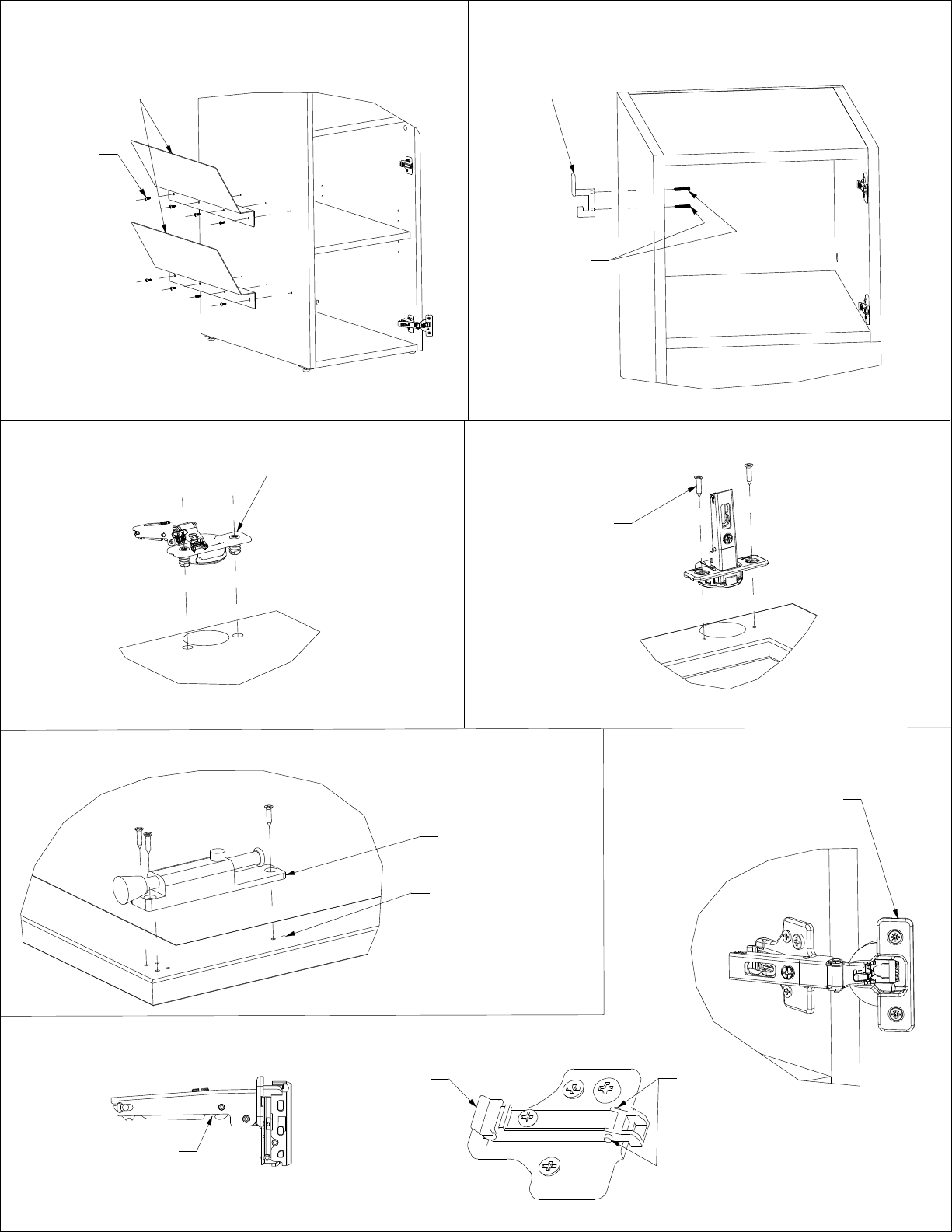

Wall Mount Cabinet/Workwall..........................36

Wall Mount Filler Strip........................................38

Surface Mount Units.............................................40

Surface Mount Inserts..........................................42

External Tops.........................................................43

Legs..........................................................................46

Riser/Laptop Tray Attach.....................................49

External Stiffener...................................................51

24D Credenzas-Bridges-Returns HGT ADJ......52

Full MOD and Half MOD HGT ADJ................56

Telescoping HGT ADJ..........................................60

Shrouded T Height ADJ.......................................75

Height Adjustable Settings...................................80

Bookcase Height ADJ...........................................78

Height Adjustable Electrical Setup......................81