INTRODUCTION

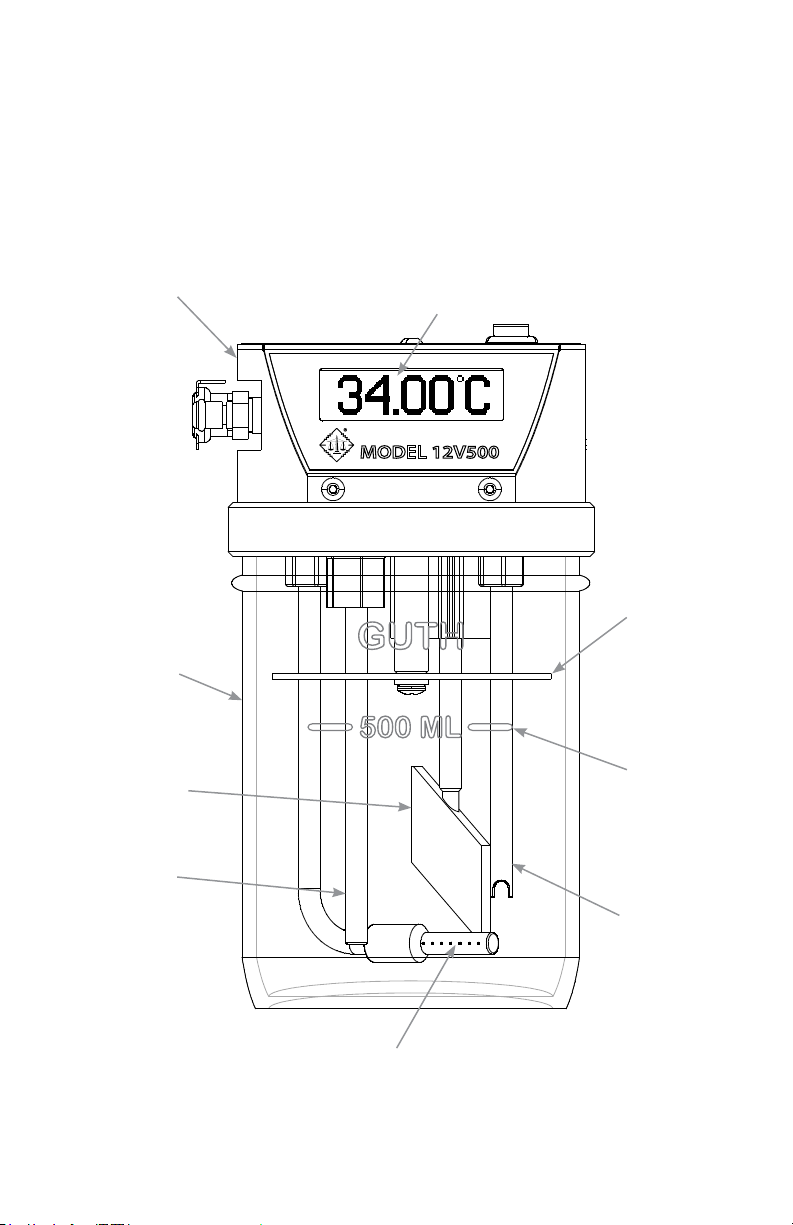

The Guth Model 12V500 Alcohol Breath Simulator is a State-of-the-Art, electroni-

cally temperature controlled, water-alcohol instrument for the purpose of providing

a precise calibration standard for testing or calibration of alcohol breath analyzers.

The Model 12V500 is the rst simulator of its kind to incorporate dual temperature

probes to independently control and monitor the temperature of the solution. The

temperature of the water-alcohol solution placed in the simulator is maintained at

34° C ± .05° C or better. The inlet and outlet port pathways have been designed to

be an integral part of the one piece heated aluminium top housing thus allowing

uniform heating and reduction of condensation. The new LCD graphics display has

a temperature resolution of .01° C and will display simulator status to the user in

the form of messages and status codes. As with all Guth products the 12V500 has

been engineered using the highest quality components to give reliable, accurate and

trouble free operation.

CERTIFIED SIMULATOR SOLUTION STANDARD

PLEASE NOTE: It is imperative your Simulator Solution be of the highest quality in

ordertoacquirethescienticandlegalstandardsofacceptance.

To establish a precise and accurate calibration standard when using a Guth Simulator,

GUTH LABORATORIES, INC. recommends using Guth Certied Simulator Solu-

tion. Guth Laboratories, Inc., a pioneer and leader in the science of alcohol breath

testing, has provided Certied Simulator Solution to state, municipal, and local law

enforcement agencies for many years.

************

All Guth Certied Simulator Solutions are traceable to NIST (National Institute of

Standards and Technology).

************

Guth Certied Simulator Solutions are prepared in standard concentrations of .02%,

.04%, .05%, .08%, .10%, .15%, .20%, and .30%. Other special concentrations are

available upon request. Please contact Guth Laboratories, Inc. for availability and

pricing:

Toll Free: (800) 233-2338 Fax: (717) 564-2555

or visit our web site at: www.guthlabs.com

STORAGE: Store Simulator Solution in a cool location. Do not place

solution in a freezer.

- DO NOT REFRIGERATE SIMULATOR

1