SEPARATION IN THE CONTRACTION CHAMBER

.5 .5

Separation of mercury in the contraction chamber is an entirely different problem. Many

thermometers contain scale ranges which begin well above ambient temperatures. These

thermometers are provided with a contraction chamber or enlargement which prevents the

mercury from entering the bulb at ambient temperatures. Unusual handling of the themometer

may cause a separation in the contraction chamber.

The procedure to rejoin this mercury is relatively simple. If the separated mercury is in the

form of a very slight amount, invert the thermometer and tap gently against the palm of the hand.

(It is recommended that protection be used in the palm of the hand - paper towel, cloth, etc.

against glass breakage.) This will cause a greater separation, adding volume and weight to the

separated portion. The thermometer should then be righted and gripped firmly in the hand with

bulb outward. Sharply swing the thermometer downward at one's side in a 270 to 180 degree arc.

The centrifugal force thus generated will join the separated mercury to the main portion. If the

original separation contained a large volume, only the latter step of swinging the thermometer

downward need be followed.

SEPARATION IN THE LOWER AND MIDDLE PORTION OF THE COLUMN

.5 .5

Separations of this type are less frequent and more difficult to repair. There are more variables,

and no one explanation will cover all types of thermometers.

The general procedure is to subject the bulb only to a temperature (in an ice bath or freezer)

sufficient to retract all the mercury into the bulb. A slow and careful return to ambient

temperature will return an intact column. Our experience has shown that additional problems may

be caused in these procedures, and we point out the following cautions:

Allow thermometer to return to ambient or room air slowly, or breakage may occur. This

breakage is caused by mercury thawing in the capillary more slowly than the mercury in the bulb

thereby creating an impasse to the expanding mercury. In order to avoid this breakage, extreme

care must be taken to allow the mercury in the bulb to liquify at the same rate as the mercury in the

capillary.

Position the thermometer vertically and allow it to return to ambient temperatures. Extreme

care must be taken to insure the thermometer is not jarred or at the slightest angle while the

nitrogen gas and the mercury return into the capillary. If this care is not taken, mercury will enter

the capillary prior to the gas. This will cause gas bubbles to develop in the bulb and, in turn, cause

considerable inaccuracy which may be undetectable when the thermometer is placed into use.

1) If there is no separation, return the unit to Guth Laboratories,

Inc. (See instructions page 9).

2) If there is a separation...Try another NIST thermometer (or)

follow the instructions for rejoining a mercury separation.

CAUTION:If amercury thermometer is accidentally broken, be very careful. Mercury is

poisonous.. DO NOT allow direct contact with skin or mouth! Use rubber gloves to clean any

spill.

INSTRUCTIONS FOR REJOINING MERCURY SEPARATIONS IN GLASS

THERMOMETERS

All Guth precision thermometers are sealed under extremely high nitrogen pressure while

drawing the mercury into the lower portion of the capillary. This process, when coupled with acid

washed tubing and triple distilled mercury, although costly, greatly reduces the frequency of

separations in the capillary portion of the thermometer.

Many instructions for rejoining separations begin with "the mercury may be retracted into the

bulb by immersing it in a suitable mixture of dry ice and alcohol..." This statement is NOT

specific enough. Determine the type of separation from the illustrations provided and proceed

according to these instructions.

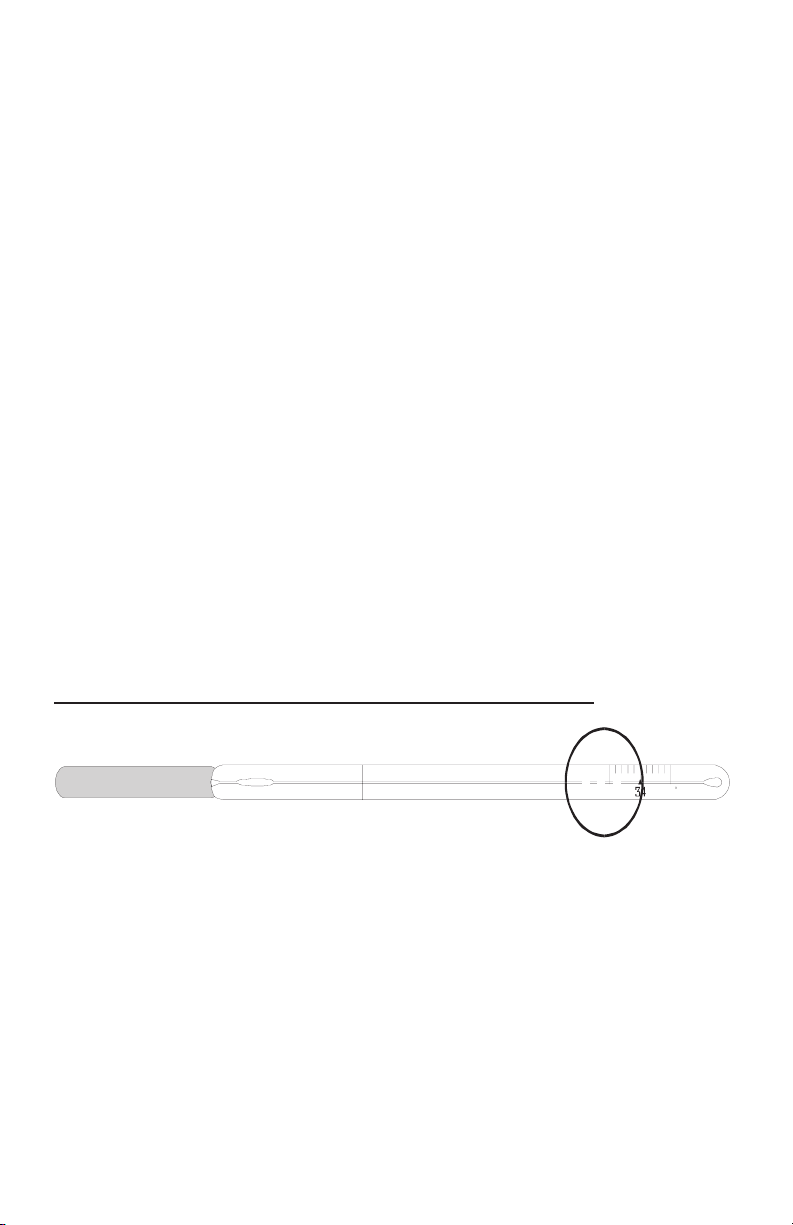

SEPARATION AT THE UPPER PORTION OF MERCURY COLUMN

.5 .5

All well constructed thermometers contain an expansion chamber or bubble at the extreme top

of the capillary. This chamber serves a twofold purpose; one, to accommodate an overflow of

mercury when the thermometer is subjected to temperatures in excess of its scale range and two, as

ameans of rejoining this type of separation.

With the thermometer in a vertical position, slowly heat the bulb under WARM tap water until

the separated segments and a portion of the main (intact) column enter the top chamber. (Extreme

care must be taken to insure that the mercury does NOT fill more than HALF to THREE-

QUARTERS of the chamber volume; otherwise, breakage of the bulb will result). The nitrogen

pressure will force a rejoining of the mercury. While positioning the thermometer vertically,

examine the column as it cools and retracts to be sure it is intact.