When possible, recharge your batteries when they about 50% discharged or earlier. This

gives the batteries a much longer life cycle than recharging when they are more deeply

discharged.

Our inverter has a battery low voltage shutdown around 20Vdc.With moderate to heavy

loads, this will protect against over-discharging the battery. if the inverter is running only

light loads it is advisable to recharge before the inverter low voltage shutdown point is

reached.

For more information on maintaining batteries, consult your battery's manufacturer.

For information about our battery chargers, please contact us.

The battery s back up time depends on the battery capacity(Ah)and your appliances

power (Watt)

The method to calculate the operation time is :

Battery capacity(Ah) x input back up / loads power(W)

For example:

Battery capacity= 150Ah

Input Voltage= 12V

Loading power= 600W

(150Ah x 12V)/600W= 3H

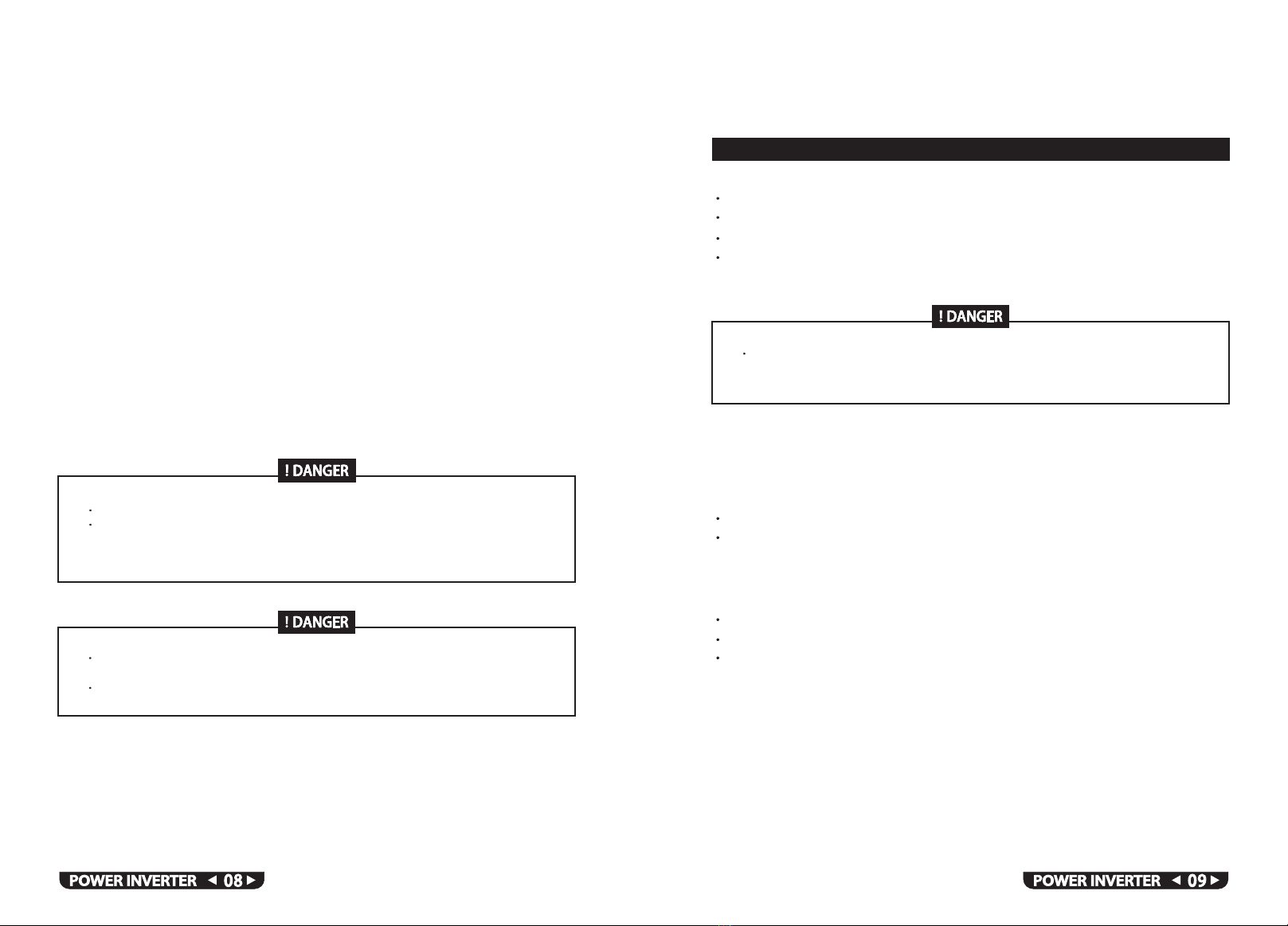

This section describes the most common problems you may encounter with the operation

of the inverter along with resolutions.

If you encounter problems other than what is described in this section, contact customer

supporting center.

16.1 COMMON PROBLEMS

16.1.1 Buzz in Audio Equipment

Some inexpensive stereo systems may emit a buzzing noise from their loudspeakers when

operated from the inverter. This occurs because the power supply in the audio System

does not adequately filter the modified sine wave produced by the inverter.

The only solution is to use a sound system that has a high quality power supply.

16.1.2 Television Reception

When the inverter is operating, it can interfere with television reception on some

channels. If interference occurs, try the following:

14.RECHARGING BATTERIES

15. BATTERY’S CAPACITY CALCULATION

16.TROUBLE SHOOTING

1. Make sure that the chassis ground screw on the rear of the inverter is solidly connected

to the ground system of your vehicle or home.

2. Make sure that the television antenna provides an adequate ( snow-free ) signal and

that you are using good quality cable between the antenna and the television.

3. Keep the cables between the battery and the inverter as short as possible, and twist

them together with two to three twists per foot. ( this minimizes radiated interference

from the cables.)

Move the television as far away from the inverter as possible.

Do not operate high power loads with the inverter when the television is on.

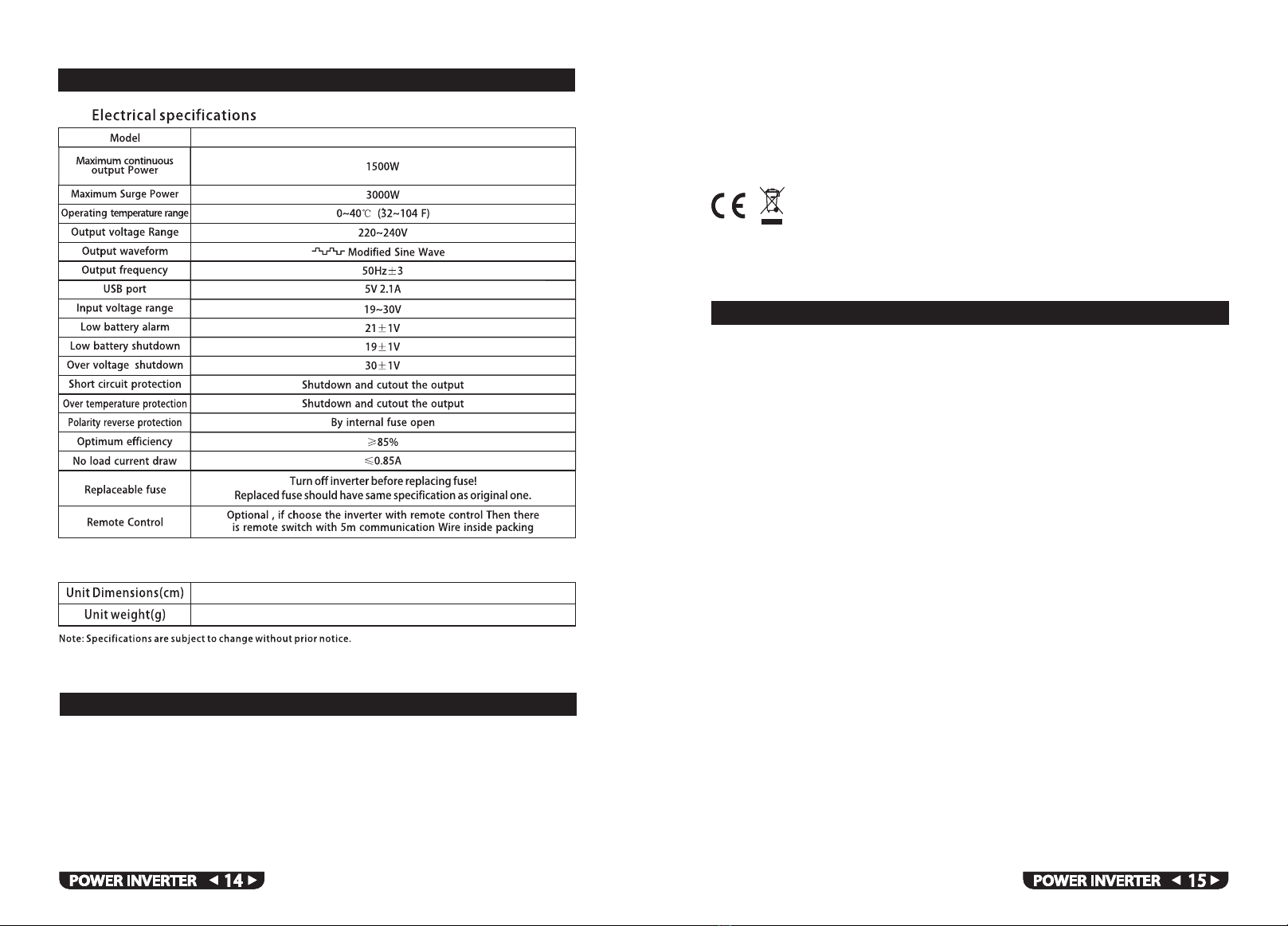

ELECTRICAL SHOCK HAZARD

Do not disassemble the inverter. It does not contain any user-serviceable parts.

Failure to follow these instructions can result in death or serious injury.

Problem Possible Cause Solution

Low output

voltage

No output

voltage.

Both the

power

light and fault

light are off

No output

voltage.

Fault light

is on

Low battery

alarm stays on

Poor DC wiring, Low battery poor

battery condition

Low input voltage

High input voltage

Thermal shutdown

Unit overload

Output is short circuited

The inverter is off.

No power to the inverter.

The inverter could have been

connected with reverse DC input

polarity

You are using a voltmeter that

cannot accurately read the RMS

voltage of a modified sine wave.

Low input voltage and the load is

close to maximum allowable power

Use a true RMS reading voltmeter such as

the Fluke87.

Check the connections and cable to see if

the battery is fully charged.

Recharge the battery if it is low.

Reduce the load.

Recharge the battery, check the connections

and cable. Make sure the

inverter is connected to a correct battery

(24V inverter for 24V batteries bank) Allow

the unit to cool off. Reduce the load if

continuous operation is required. Improve

ventilation. Make sure the inverter s

ventilation openings are not obstructed.

Reduce the ambient temperature. Reduce

the load. Make sure the load does not

exceed the inverter s output rating.

Remove the short circuit

Turn the inverter on.

Check the wiring to the inverter and to

the battery selector switch (if installed).

The inverter has probably been damaged.

Return the unit, damage caused by reverse

polarity is not covered by the warranty

Use proper cable size and lengths and make

solid connections

Charge the battery Install a new battery

16. 2 TABLE 1 TROUBLESHOOTING REFERENCE