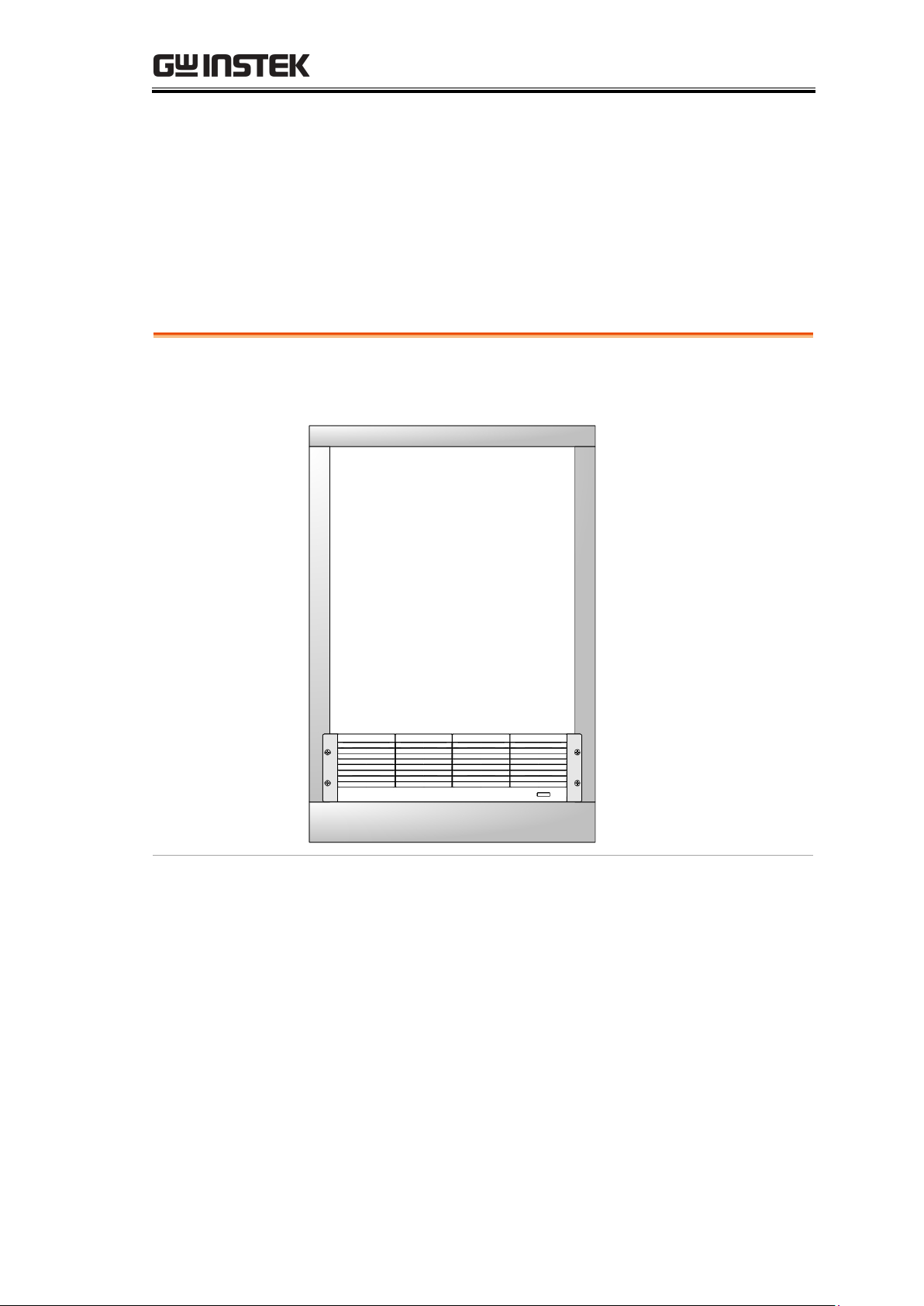

PEL-3000H Series Parallel Assembly Guide

4

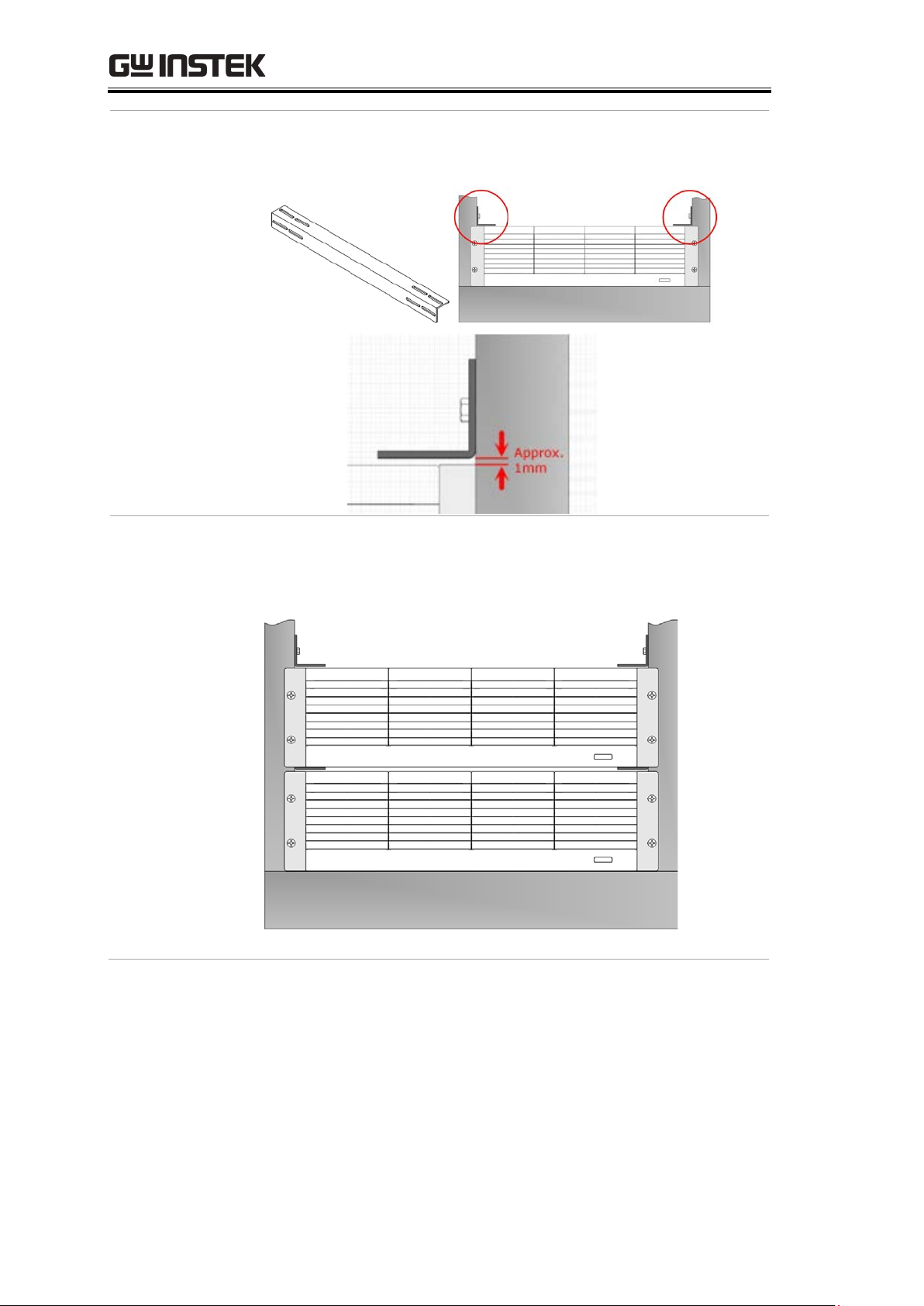

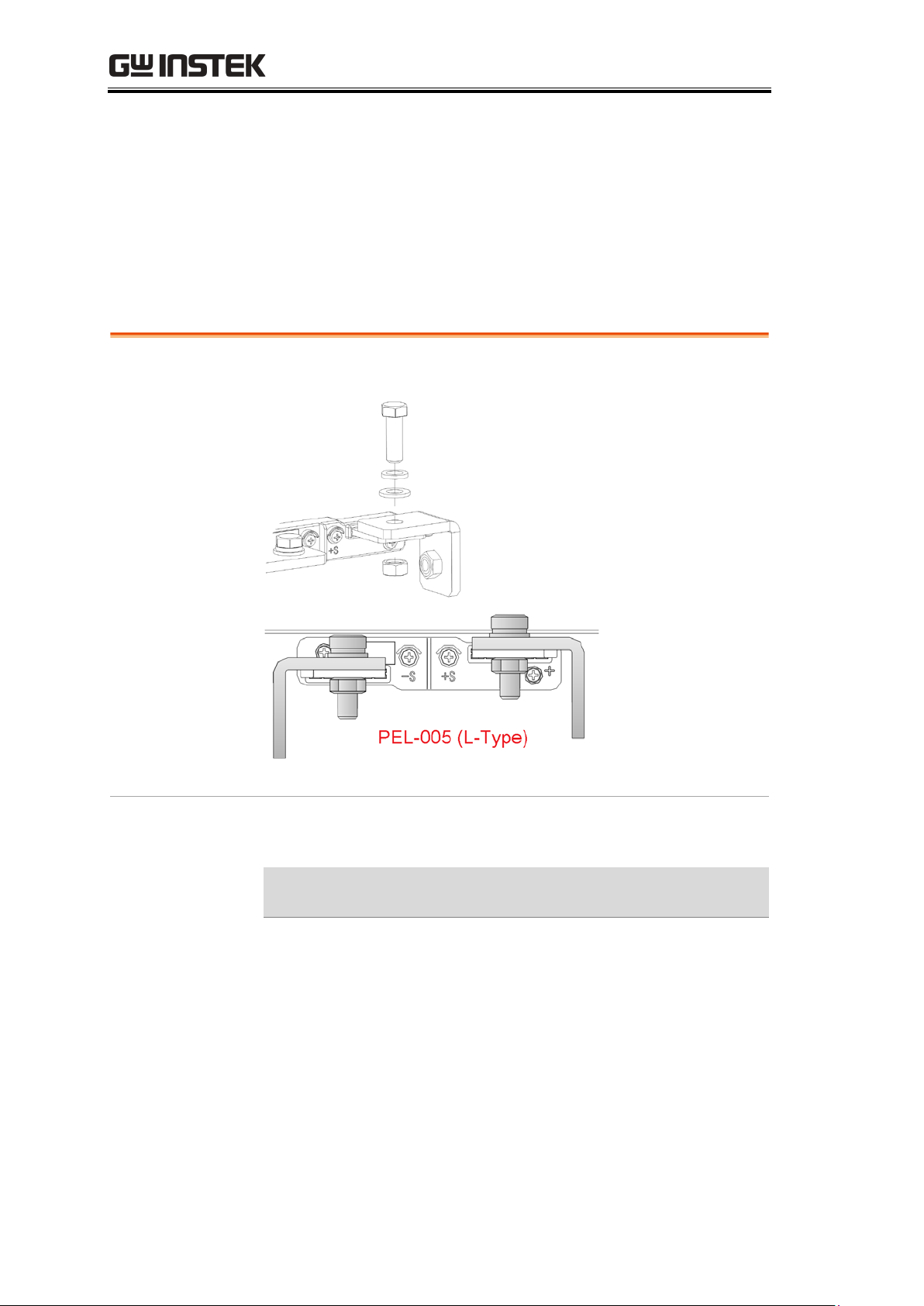

L-shape brackets in the interior side of rack. An approx. 1mm

distance between the bottom o

f brackets and the top of PEL-3211H is

-3211H onto the L-shape brackets within the rack and,

fasten the 4 screws for side bracket in the front but not tighten

fully followed by screwing another group of L-shape brackets

within the interior of rack.

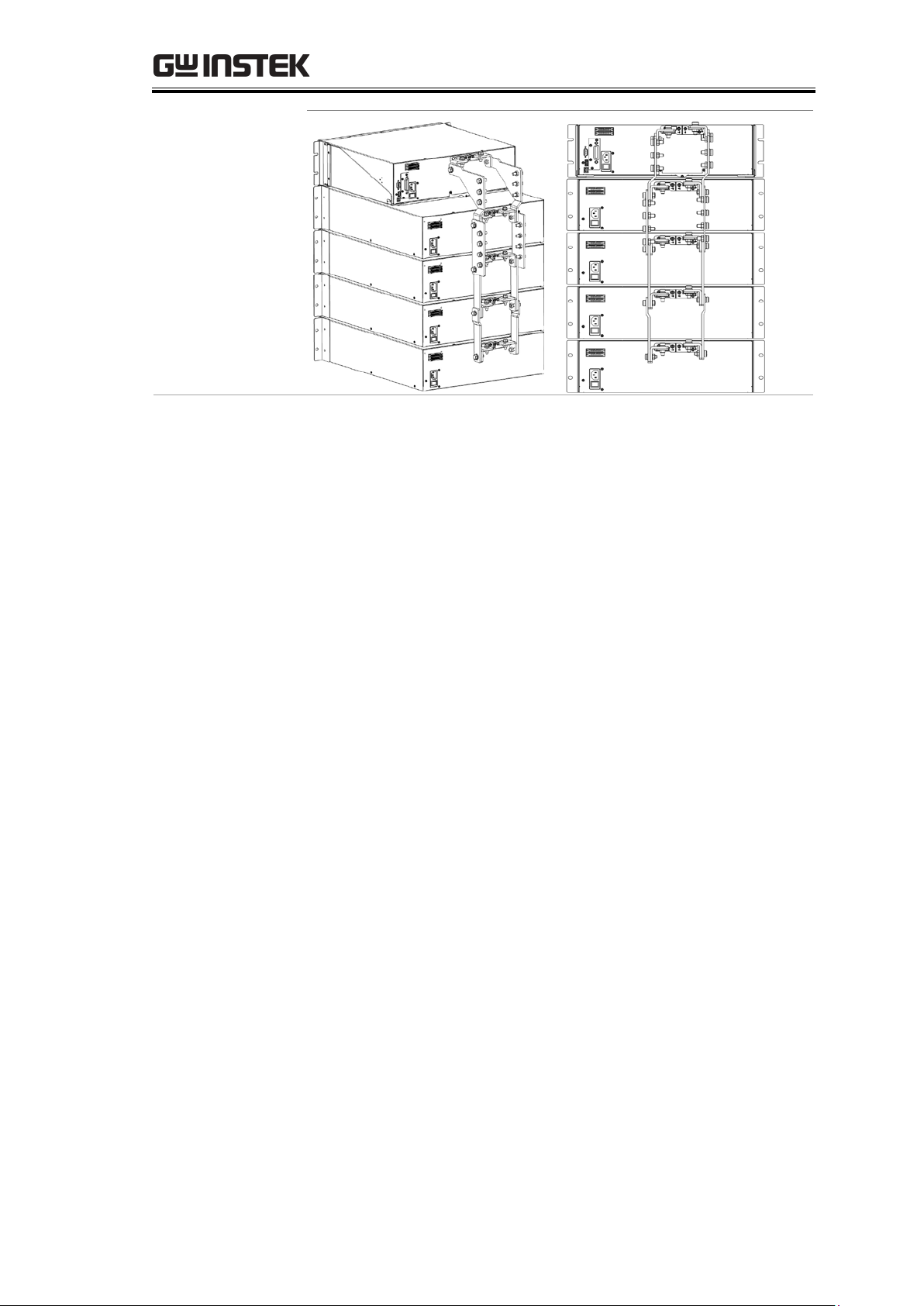

2nd unit installation completion

L-shape

bracket

The L-shape brackets screwed

on the interior side of rack

bracket and the top of unit