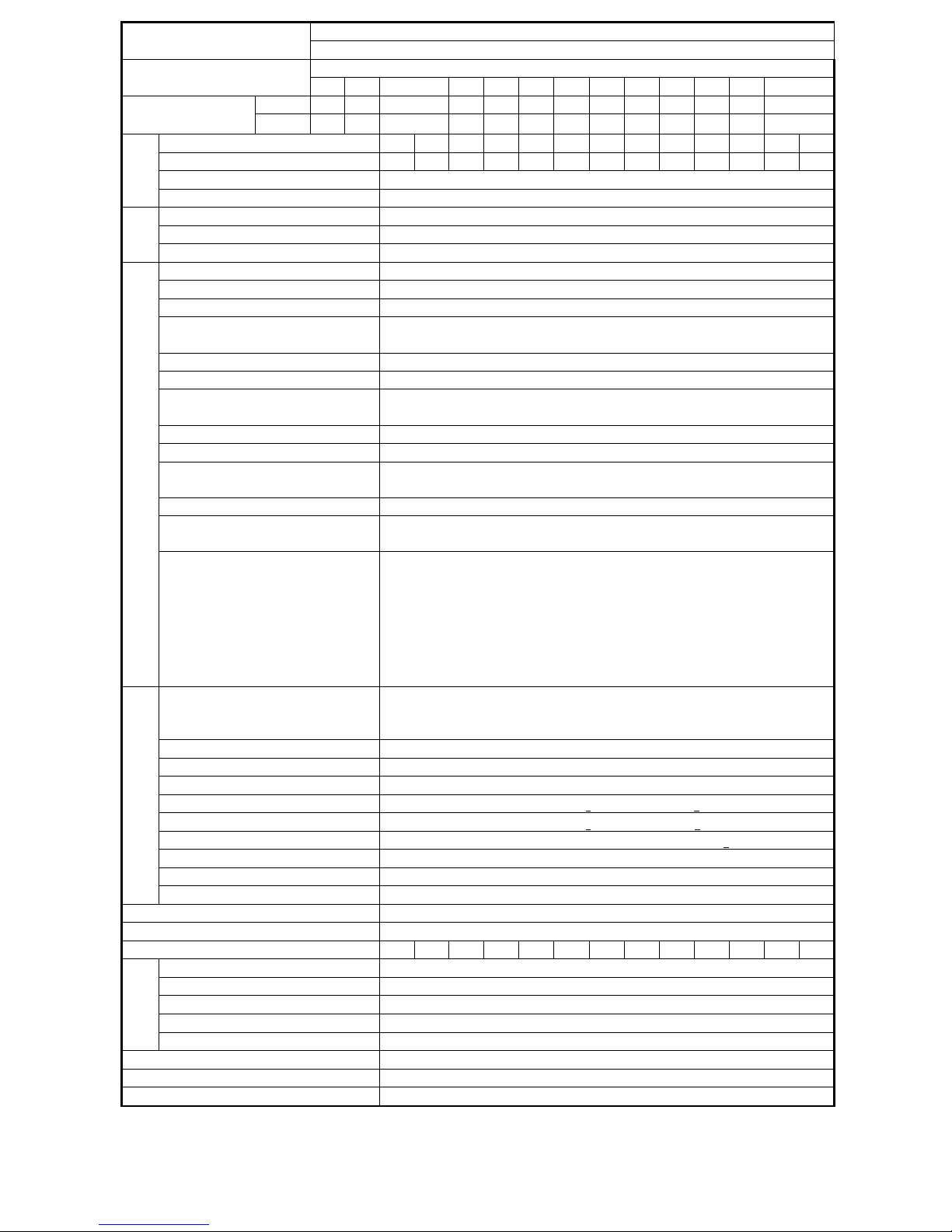

GWAN HSIAN ELECTRIC&MACHINERY CO.,LTD 6

440V Class

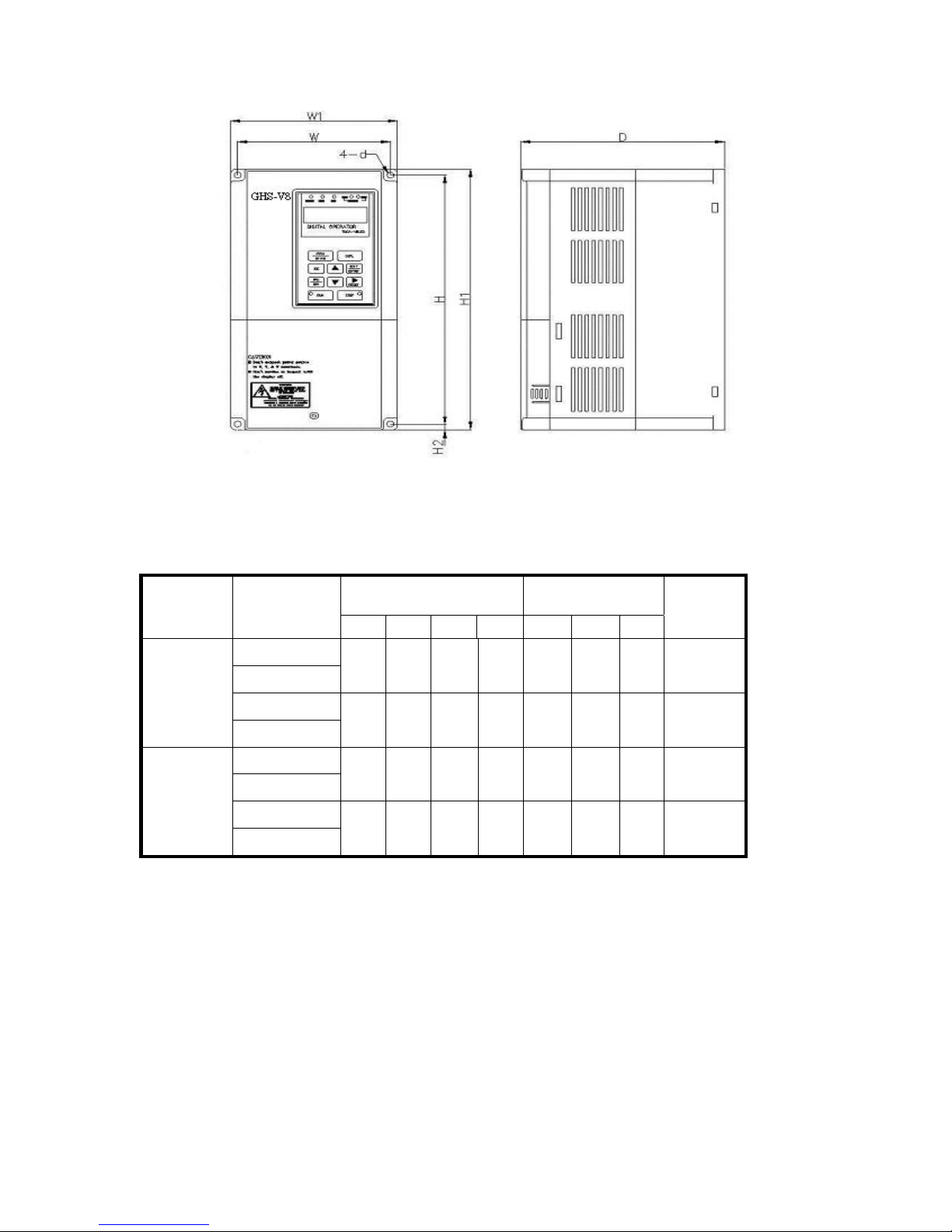

Input Voltage Class 3 phase

GHS-V8-

MODEL 0P7 1P5 2P2 3P7 5P5 7P5 011 015 018 022 030 037 045

HP 1 2 3 5 7.5 10 15 20 25 30 40 50 60

Max. Applicable

Motor Output (CT)* kW 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45

Rated Output Capacity (kVA) 2.1 2.7 4 7.5 10.1 13.7 20.6 27.4 34 41 54 68 82

Rated Output Current (A)* 2.6 4.0 4.8 8 12 16 24 32 40 48 64 80 196

Max. Output Voltage (V) 3 phase 200~230V

Output Power

Max. Output frequency(Hz) Through parameter setting ( 0 Hz to 400Hz)

Rated Voltage, Frequency 3 Phase 200V~230V, 50/60Hz

Allowable Voltage Fluctuation -15% ~ +10%

Power

Source

Allowable Frequency Fluctuation ±5%

Operation Mode LED operator or LCD operator。

Control Mode Sinusoidal PWM

Frequency Control Range 0.5Hz~400Hz

Frequency Accuracy

(varied with temperature)

Digital Command:

±

0.01%(-10 ~ +40℃)

Analog Command:

±

0.1%, (25

±

10ºC)

Frequency Command Resolution Digital Command: 0.01Hz Analog Command: 0.06Hz/60Hz

Frequency Output Resolution 0.01Hz

Overload Resistibility (constant torque)150% Rated Current for 60 sec;

(varied torque) 120% rated Current for 60 sec

Frequency Setting Signal DC 0 ~ +10V / 4 ~ 20mA

Acc./Dec. Time 0.0 to 6000 Seconds (Independent Accel/Decel Time Settings)

Voltage-Frequency

Characteristics Adaptable V/f through parameter setting

Regeneration Torque 100%,2%ED,5 秒

Main Control Function Auto Torque Boost, Slip Compensation, Restart After Momentary Power Loss, Energy-Saving, PID

Control, RS-485 Communication, Simple PLC Function, Sensorless Vector Control

Control Characteristics

Extra Function

Up/Down Operation, 4 Different Sets of Fault Status Record (Including Latest One), Cumulative

Power On & Operation Hour Memory, Energy Savings Function, MODBUS Communication,

Multiple-Pulse Output Ports, etc.

Stall Prevention

During Acceleration/Deceleration and Constant Speed Operation

(Current Level can be Selected During Acceleration and Constant Speed Operation. During

Deceleration, Stall Prevention can be Enabled or Disabled)

Instantaneous Overcurrent (OC) 200% of Rated Output Current

Inverter overloads Protection(OL2) Motor Coasts to Stop after 1 Minute at 150% Rated Output Current

Motor Overload (OL1) Electronic Overload Protection

Over voltage(OV) Motor Coasts to Stop if VDC

>

410V (230V) or VDC

>

820V (460V)

Low voltage(UV) Motor Coasts to Stop if VDC

<

200V (230V) or VDC

<

400V (460V)

Momentary Power Loss Ride-Through time Motor Coasts to Stop after Momentary Power Loss Lasting

>

15ms

Overheat (OH) Protection by Thermistor

Grounding Protection (GF) Protection by the DC Current Sensor

Protection Function

Charge Indication Lit when the DC Bus Voltage ≧50V

Mechanical Construction Enclosed, Wall-Mounted Type (NEMA-1)

Cooling Forced

Weight(kg) 7.1 7.1 13.1 13.1

Location Indoor (Protected from Corrosive Gases and Dust)

Ambient Temperature +14 to 104oF, -10 to +40ºC (Not Frozen)

Storage Temperature -4 to 140oF, -20 to +60ºC

Humidity Below 90%RH (Non-Condensing)

Environmental

Conditions

Altitude, Vibration Below 3300ft. (1000m), 5.9m/S2 (0.6G), (JISC0911 Standard)

Communication Function RS-485 Installed (MODBUS Protocol)

EMI Meets EN50081-2 (1994) With TECO Specified EMI Filter

EMC Compatibility Meets Pr EN50082-2