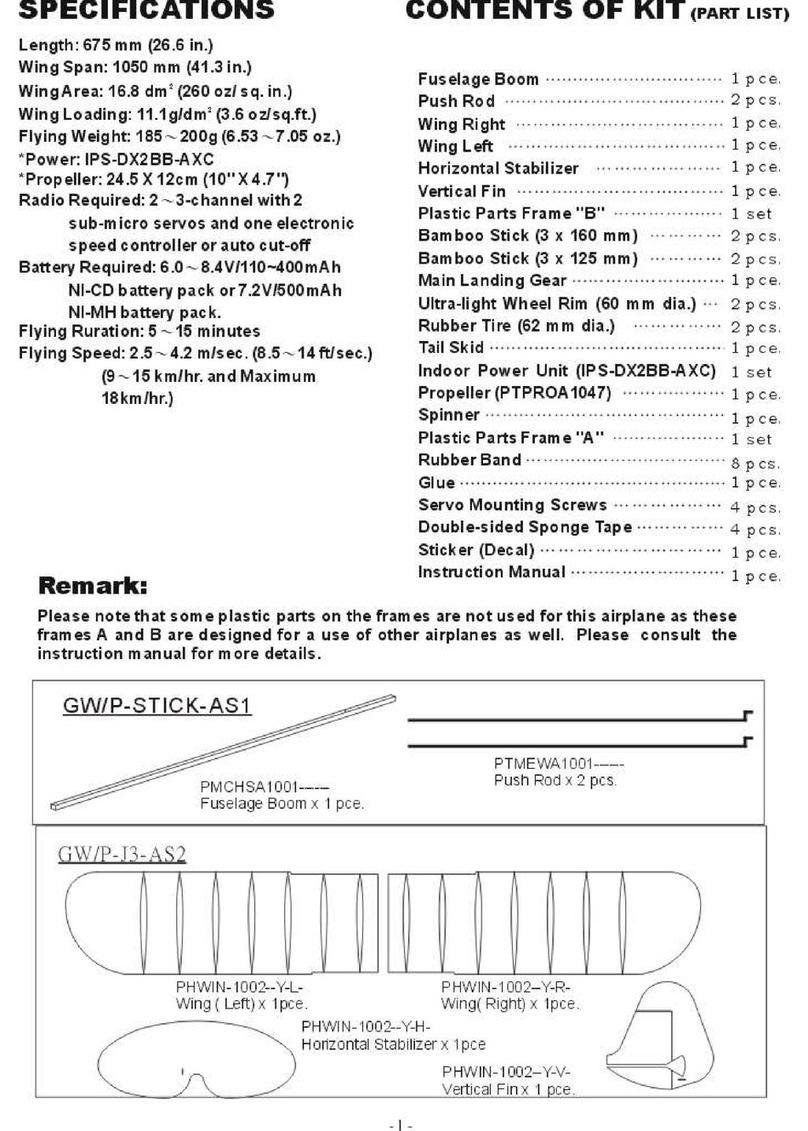

£^s7:4/fr£/f

RJC

ELECTRIC

AIRCRAFT

Step2

Apply epoxy glue to the

slot of fuselage,then put

the C (6) in place.

FUSELAGE

ASSEMBLY

Press

the

3mm

hexagonal

nut

into

the

plastic

c

(6) and apply a small amount of CA glue to the

c{6).

Frame"C"

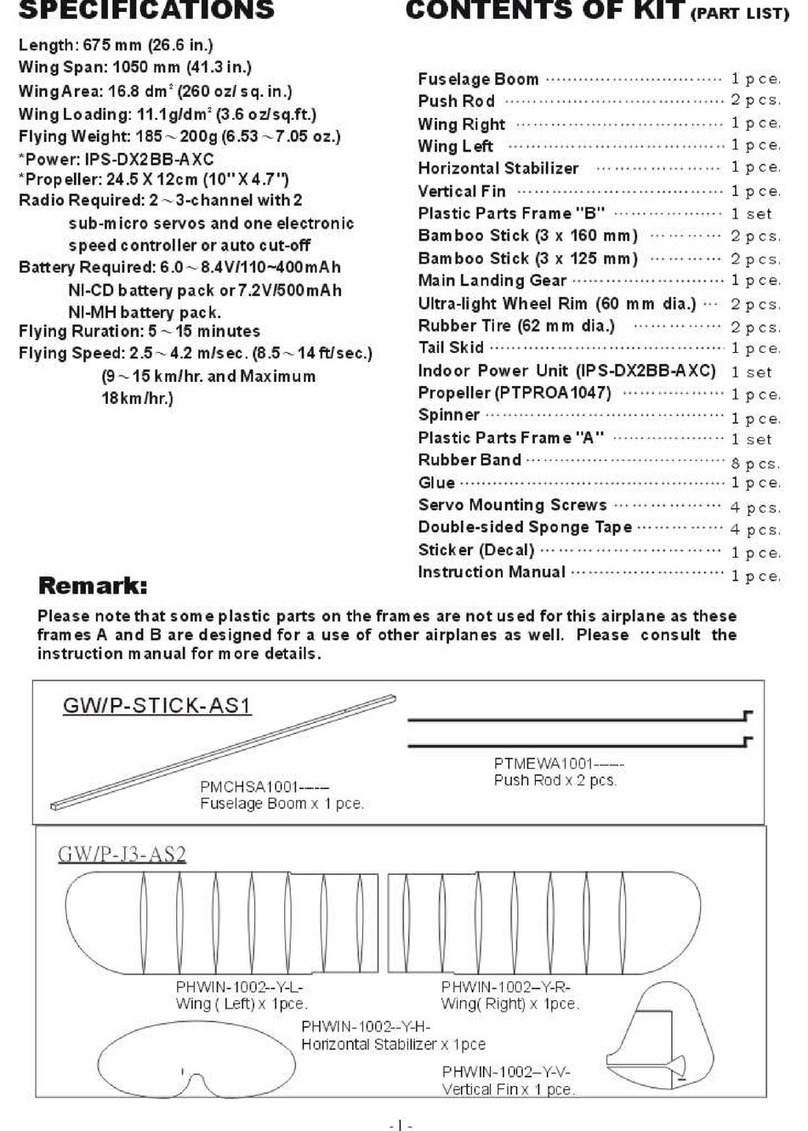

Step1

230mm 230mm

460mm

PlasticPush RodTube(Transparent)

3^x

460 mm

A Cut the plastic tube to specific length

as

shown in the picture (230mm x 2).

Glue the tube in place with

GWS glue. Insert the plastic pushtod tube (230mm)

into the hole,from inside of the fuselage

and

come

out for approximately 10mm.

Drill

3mm holes into the L& Rfuselage

pushrod guide slot.

For bigger servo, please cut

the red portion on fuselage.

i

^i ^

[r.avoSDmAh {

Bra

•

For bigger batteries,

please

cut the red portion.

/S glue at the indicated area.

Tastercure time, you may use a 6-

'minute epoxy instead ofthe included glue.

I

Step3

Once glued, fixin places in 5 or 6 position using either a very low

tach masking tape and secure with tape that

does

not come in contact

with the painted foam.