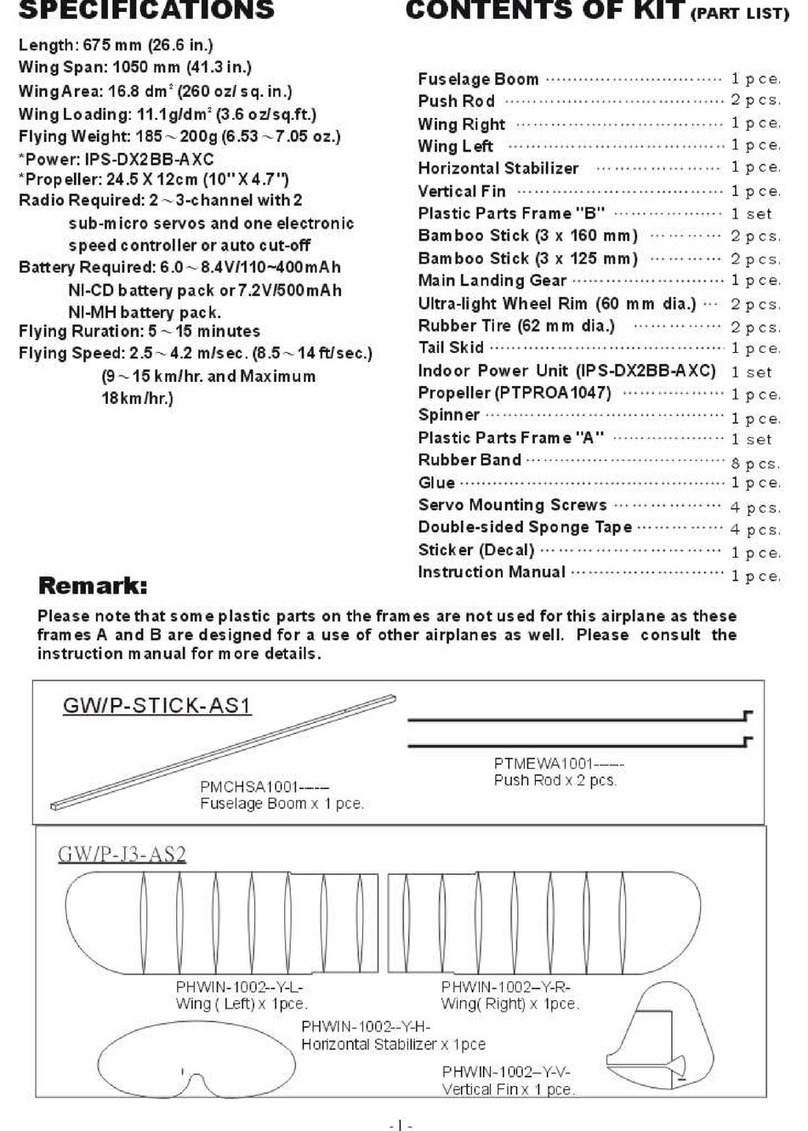

PT-IT

Frame

C

(idf^C)

Plate

3mm

Nut

use

CA

glue

Use

Paper

Tape

Kmmm^

Use

GWS

Glue

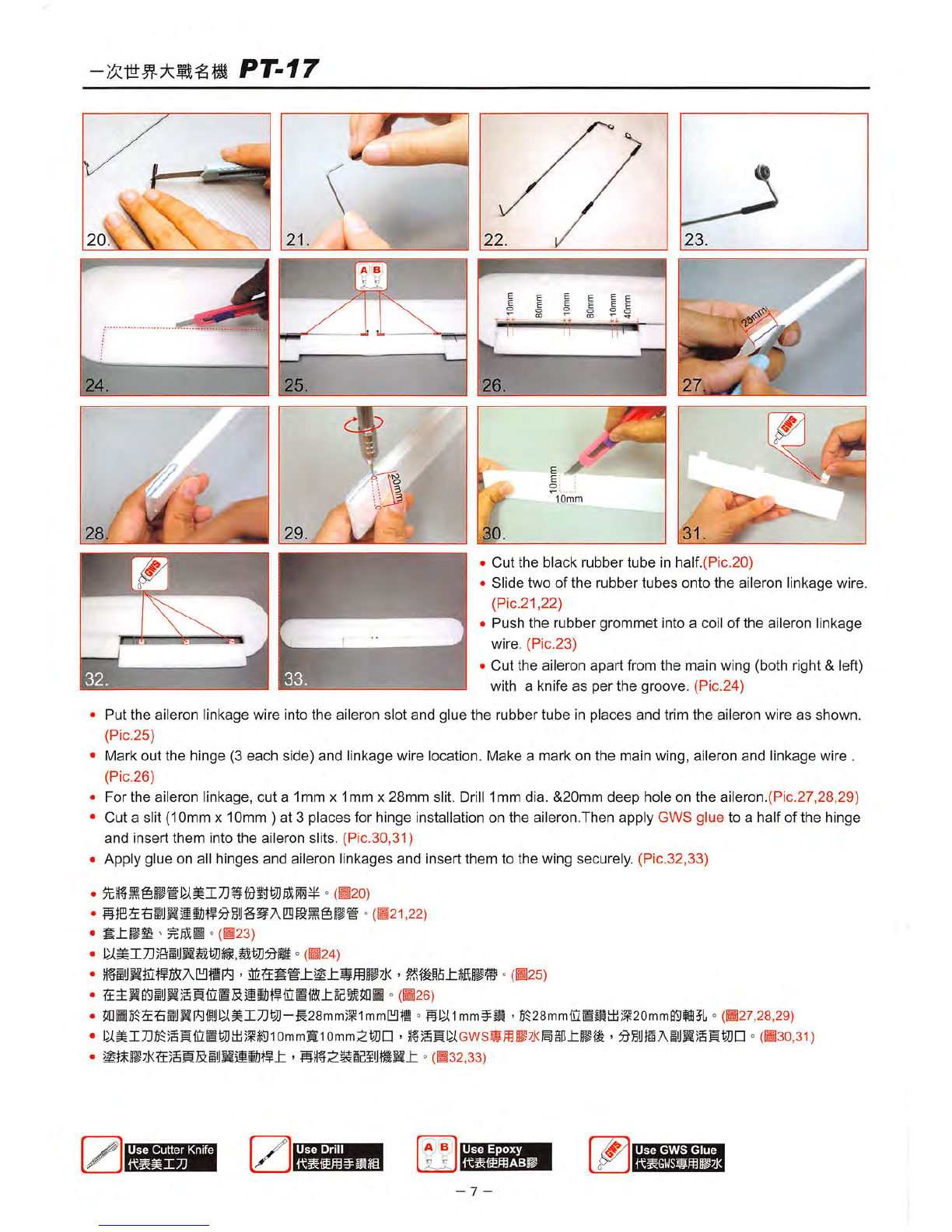

•Insert

the

"C"6 Into

the

slot of

the

fuselage

and

glue Itsecurely. (Pic. 5,6,7,8)

• Apply GWS glue at the Indicated area. For faster cure, you may use a 6-minute epoxy Instead of the Included glue. (Pic.9)

•Once glued, fixin 5 or 6 places using either a very lowtach masking tape or

secure

with tape that

does

not come in

•

contact

with

the

painted

foam,(Pic.10)

which

can

remove

paint.

•

Smm^BMAIBffC.S

> ° (H5,6,7)

•JDHffiAC.e =

(B8)

• o(B9)

• -

(Bio)

POWER

SYSTEM

INSTALLATION

A)

05

S

it

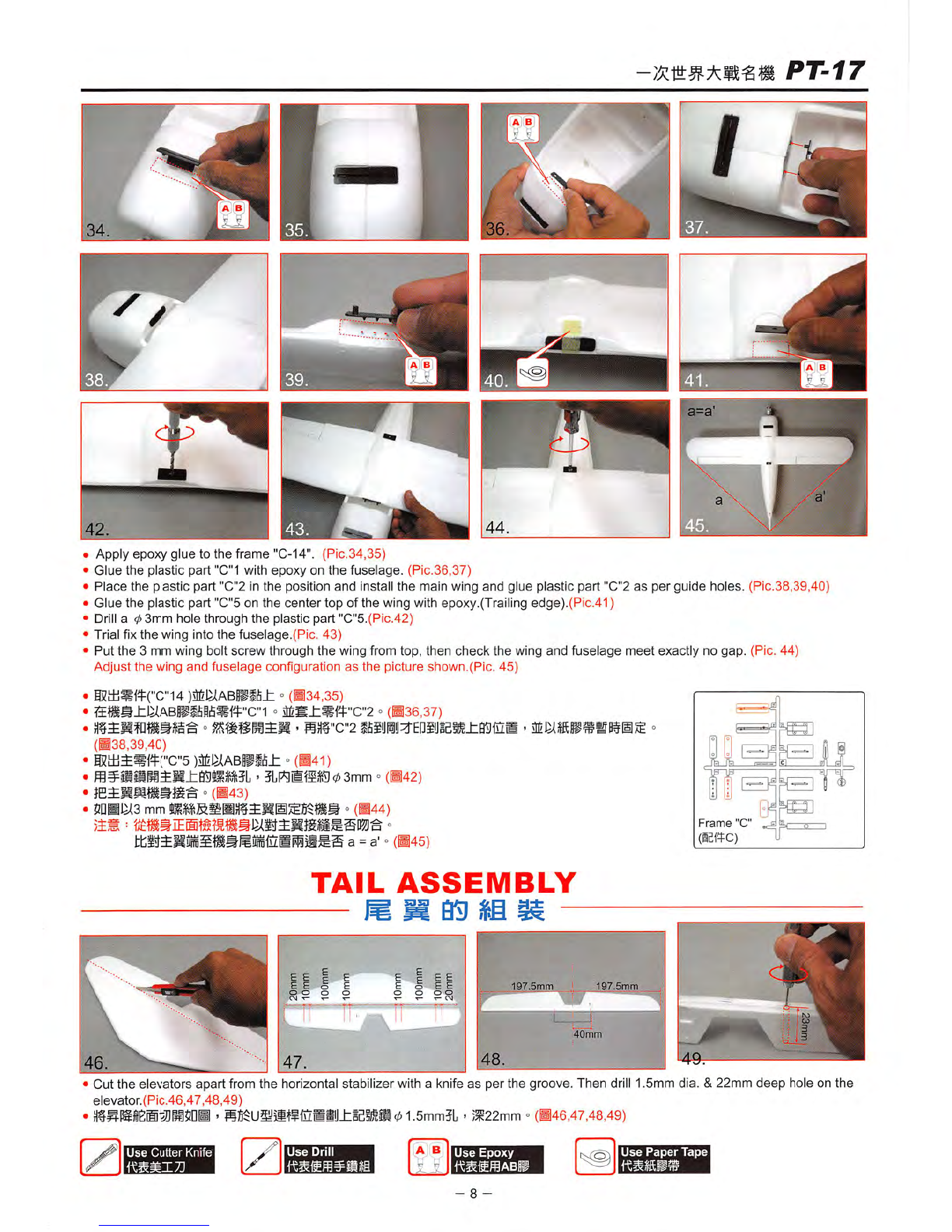

CAUTION:

Before

assemble

the fuselages,

check

which version of power

system

(EPS-350C,

EPS-400C

or

slope

Gllder)you

purchased,

then follow according to that version's power

system

Installation.

•Prepare EPS-350C parts and insert the EPS mount to the electric power system(EPS). Make

sure

that the mount is

pushed into the EPS by 10mm, ifit is too tight to insert the mount, trim the mount slightly with knife or

sand

paper.(Pic.ll)

•

Drill

a 1mm dia. hole by

hand

drill

as

picture 12,

Secured

by a screw. (Pic.12,13)

Put the power system Inthe fuselage upper chamber, making

sure

itfits and is not too tight, then pull itout. Apply glue or

epoxy

and

Install

permanently.(Pic.14,15)

•7ti511]EPS-350C65B)A)l^ffi«fffnB)Al)$R¥si5iii!MJ

•=

(111)

• -

a£!i±¥sItmSJ@^

°(•12,13)

•

)if'

mmmmiMmmTimi:

-

ifi]KB$®»A75iu«05B:otira

°(•14,15)

Use

Drill

Use

Screwdriver

A B

Use

Epoxy

- 5 -