i

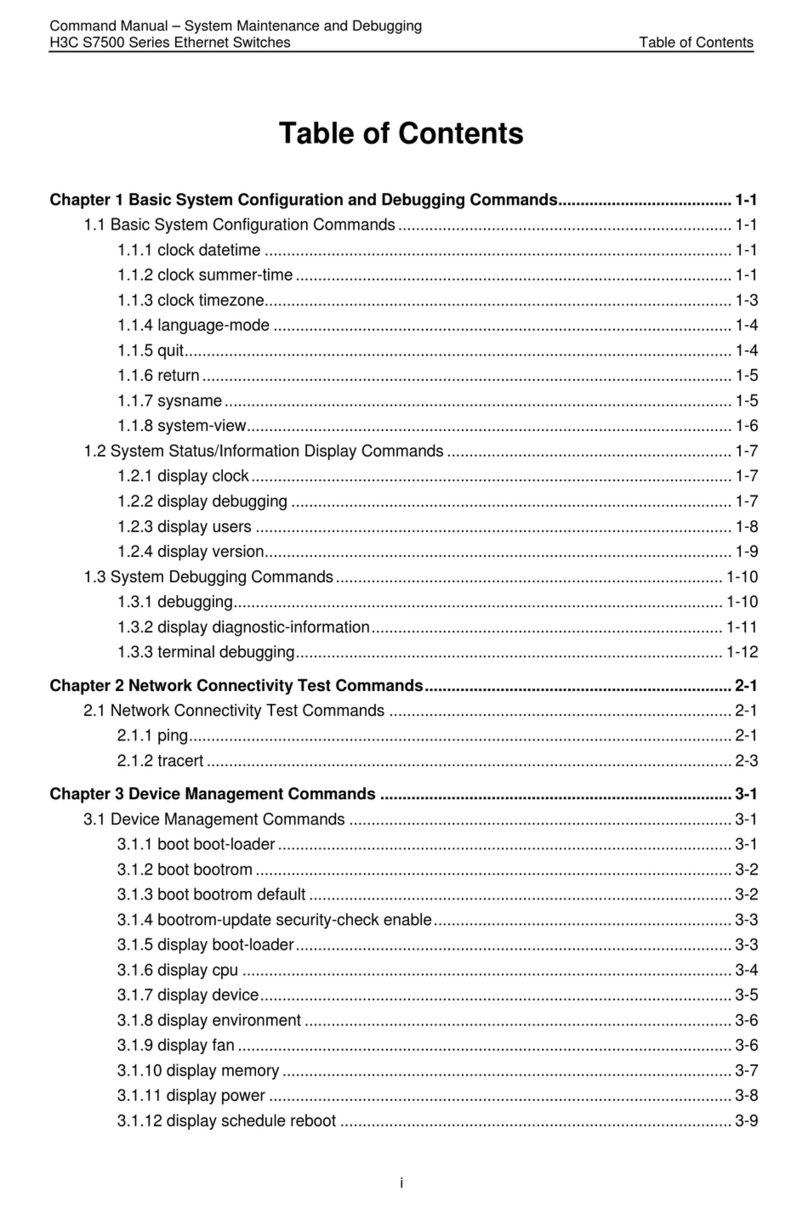

Contents

1 Safety precautions···················································································1-1

Safety labels····················································································································································1-1

Basic safety guidelines····································································································································1-2

Local laws and regulations······················································································································1-3

Basic requirements ·································································································································1-3

Grounding requirements ·························································································································1-3

Personal safety ·······································································································································1-3

Device safety···········································································································································1-4

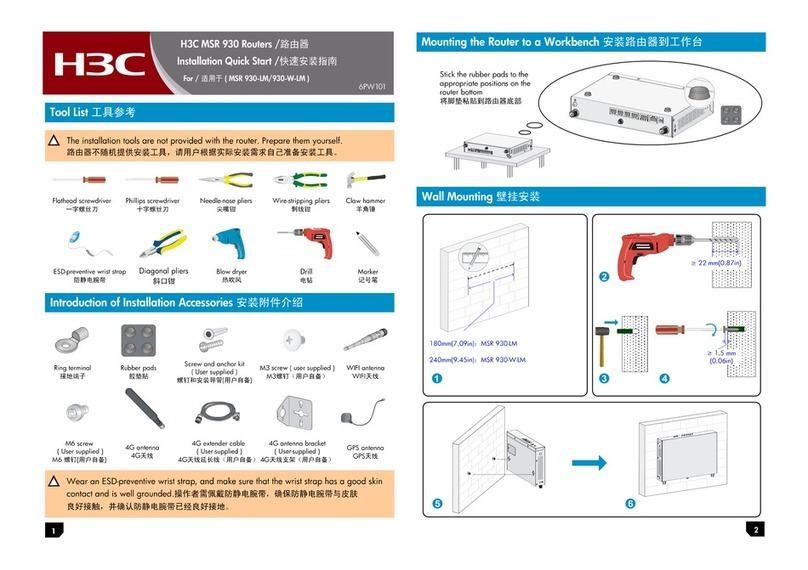

Installation site ················································································································································1-4

Basic requirements ·································································································································1-4

Indoor installation····································································································································1-4

Installation in a rack ································································································································1-5

Electrical safety···············································································································································1-5

High voltage············································································································································1-5

High leakage current·······························································································································1-5

AC and DC power supply························································································································1-5

Power cables···········································································································································1-6

Cabling····················································································································································1-6

TNV circuit···············································································································································1-6

ESD·························································································································································1-7

Laser safety·····················································································································································1-7

Mechanical safety ···········································································································································1-8

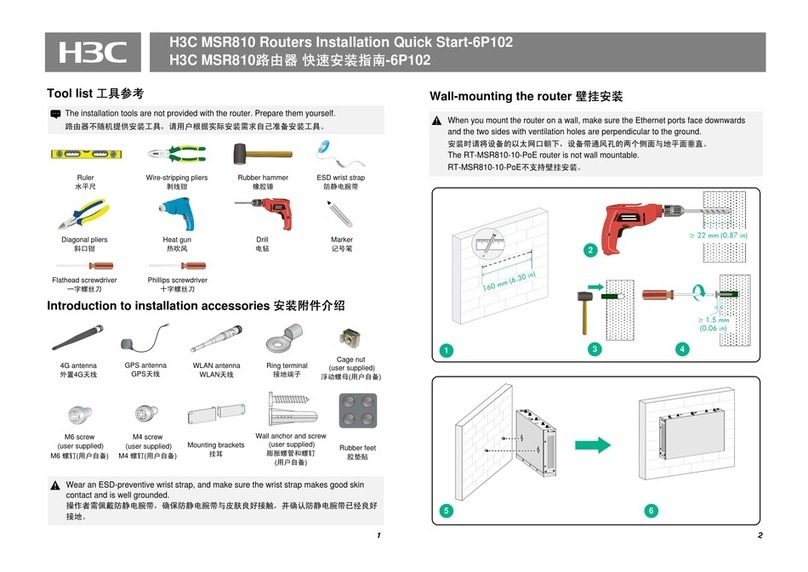

Drilling holes············································································································································1-8

Sharp objects··········································································································································1-8

Fan trays·················································································································································1-8

Moving heavy objects······························································································································1-8

Hoisting safety·········································································································································1-9

Card installation and cable connection ·········································································································1-10

Installing and removing a card··············································································································1-10

Bundling cables·····································································································································1-10

Cabling under a low temperature··········································································································1-11