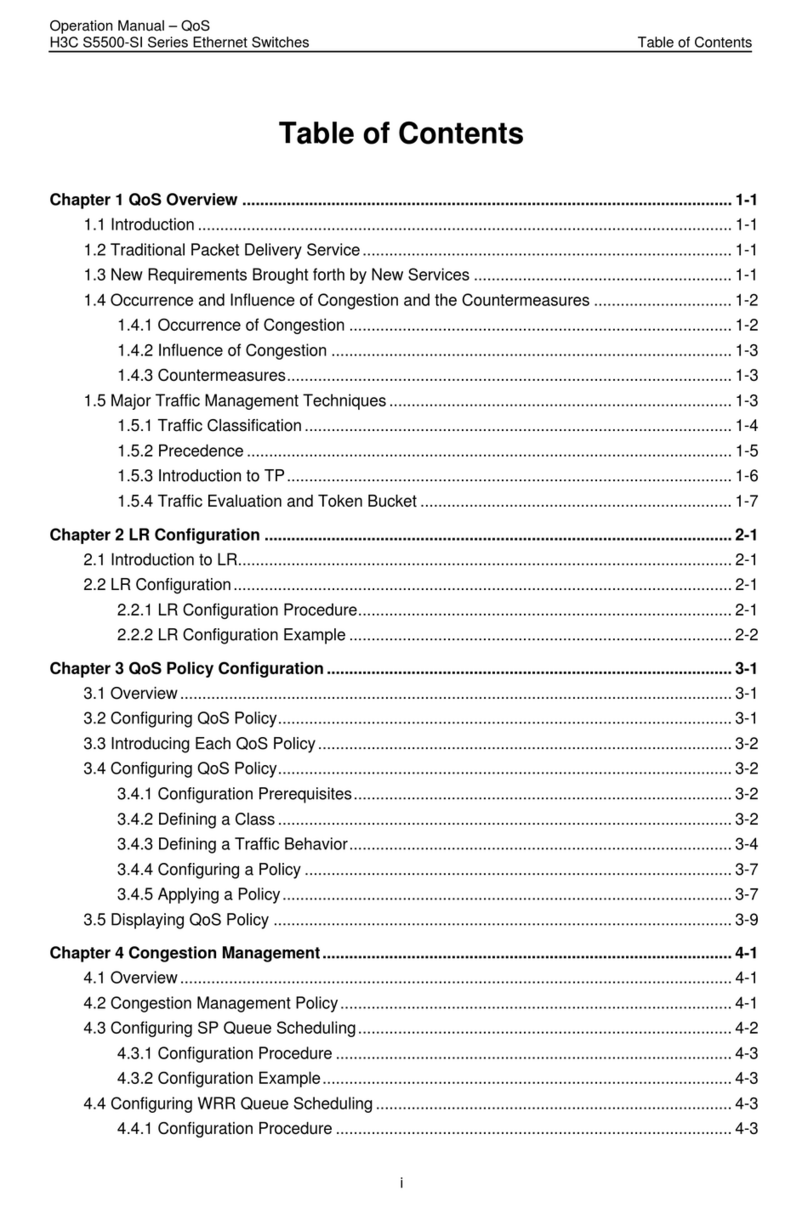

i

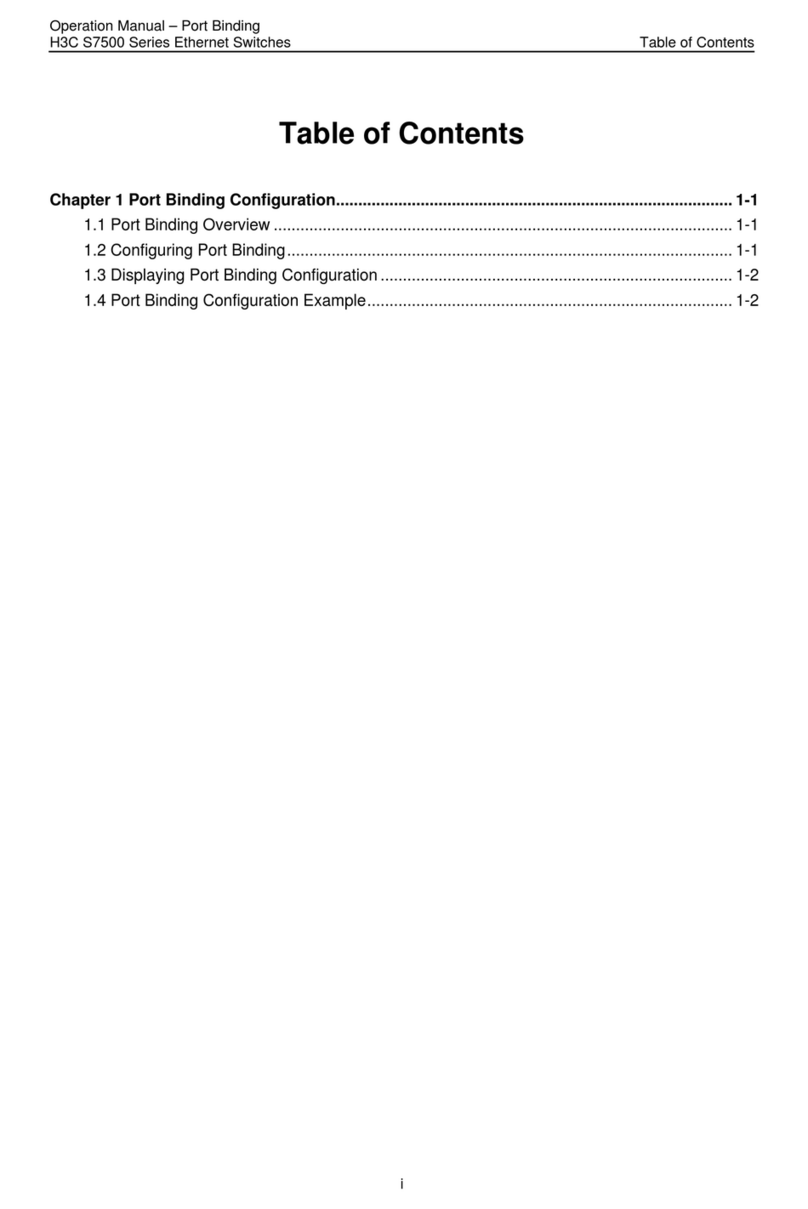

Contents

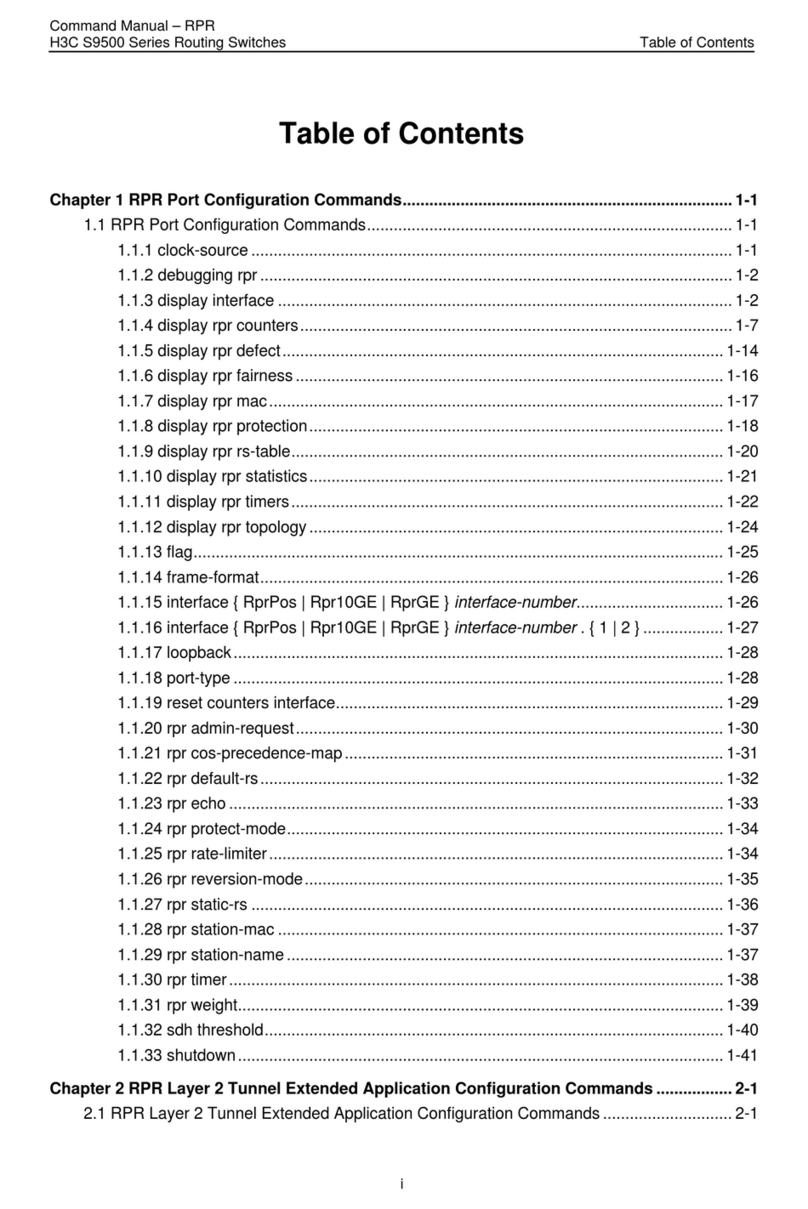

1 Preparing for installation··········································································1-1

Safety recommendations ································································································································1-1

Examining the installation site·························································································································1-1

Temperature/humidity·····························································································································1-1

Cleanliness··············································································································································1-2

EMI··························································································································································1-2

Laser safety·············································································································································1-3

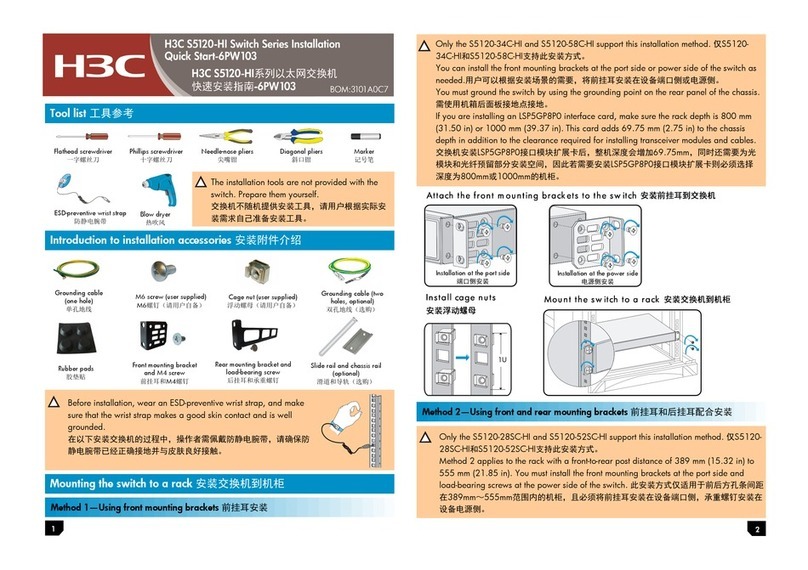

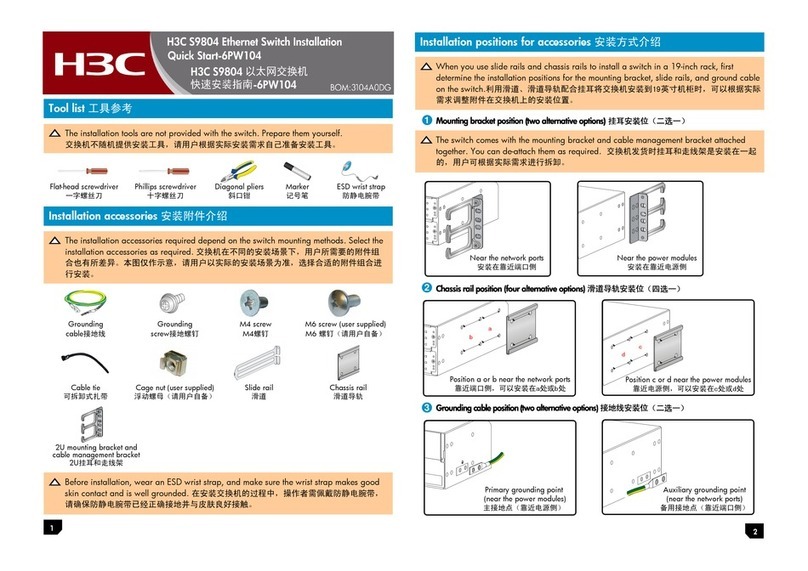

Installation tools ··············································································································································1-3

Installation accessories···································································································································1-3

2 Installing the switch··················································································2-1

Installing the switch in a 19-inch rack··············································································································2-2

Rack-mounting procedure at a glance····································································································2-2

Rack requirements··································································································································2-2

Installation accessories···························································································································2-3

Attaching the mounting brackets to the chassis······················································································2-4

Attaching cage nuts and bottom support rails to the rack·······································································2-5

Mounting the switch in the rack···············································································································2-6

Attaching the cable management frame to the rack················································································2-6

Connecting the grounding cable to the chassis ······················································································2-7

Grounding the switch ······································································································································2-8

Installing/removing fan trays ···························································································································2-9

Installing a fan tray··································································································································2-9

Removing a fan tray······························································································································2-10

Installing and removing power supplies········································································································2-11

Installing a power supply·······················································································································2-11

Removing a power supply·····················································································································2-12

Connecting the power cord for a power supply·····························································································2-13

Installing and removing interface modules····································································································2-14

Installing an interface module ···············································································································2-14

Removing an interface module ·············································································································2-16

Verifying the installation································································································································2-16

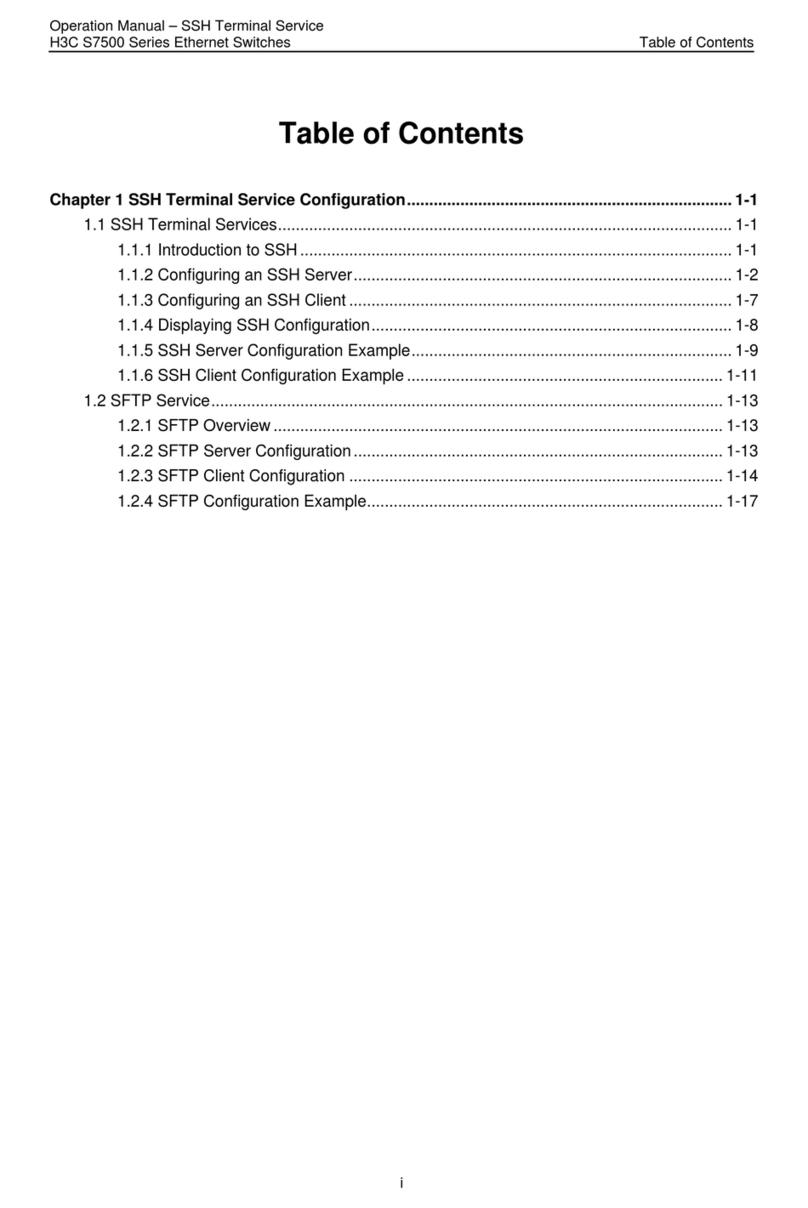

3 Accessing the switch for the first time······················································3-1

Connecting the serial console cable ···············································································································3-1

Connecting a mini USB console cable············································································································3-2

Setting terminal parameters····························································································································3-4

Powering on the switch···································································································································3-4

4 Maintenance and troubleshooting····························································4-1

Power supply failure········································································································································4-1

Symptom·················································································································································4-1

Solution···················································································································································4-1

Fan tray failure················································································································································4-1

Symptom·················································································································································4-1

Solution···················································································································································4-1

Configuration terminal display issues··············································································································4-1

No output·················································································································································4-1

Garbled output ········································································································································4-2