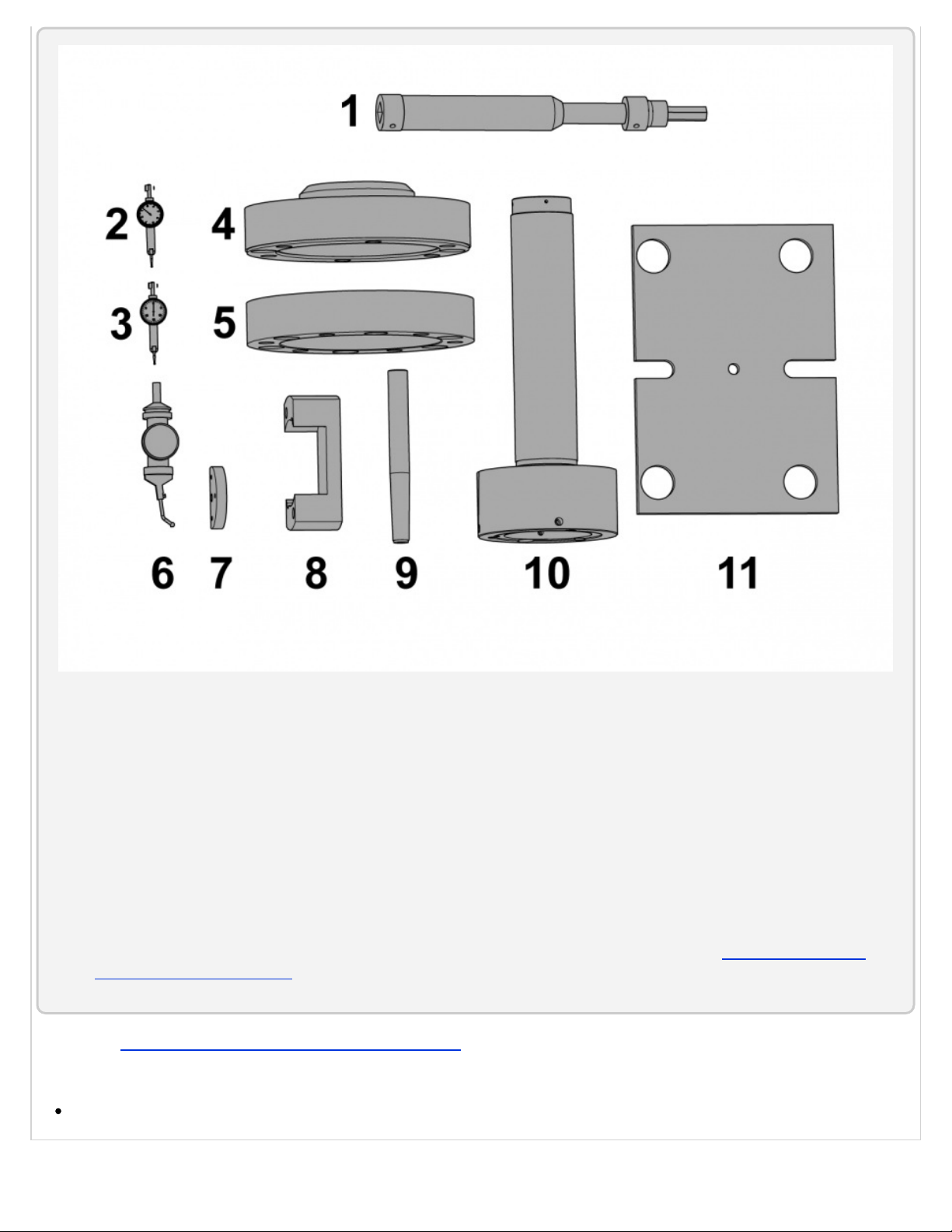

Tools Required:

1. T-0025 - 5/8" Hex Extension for ST-20/30 Spindle Head

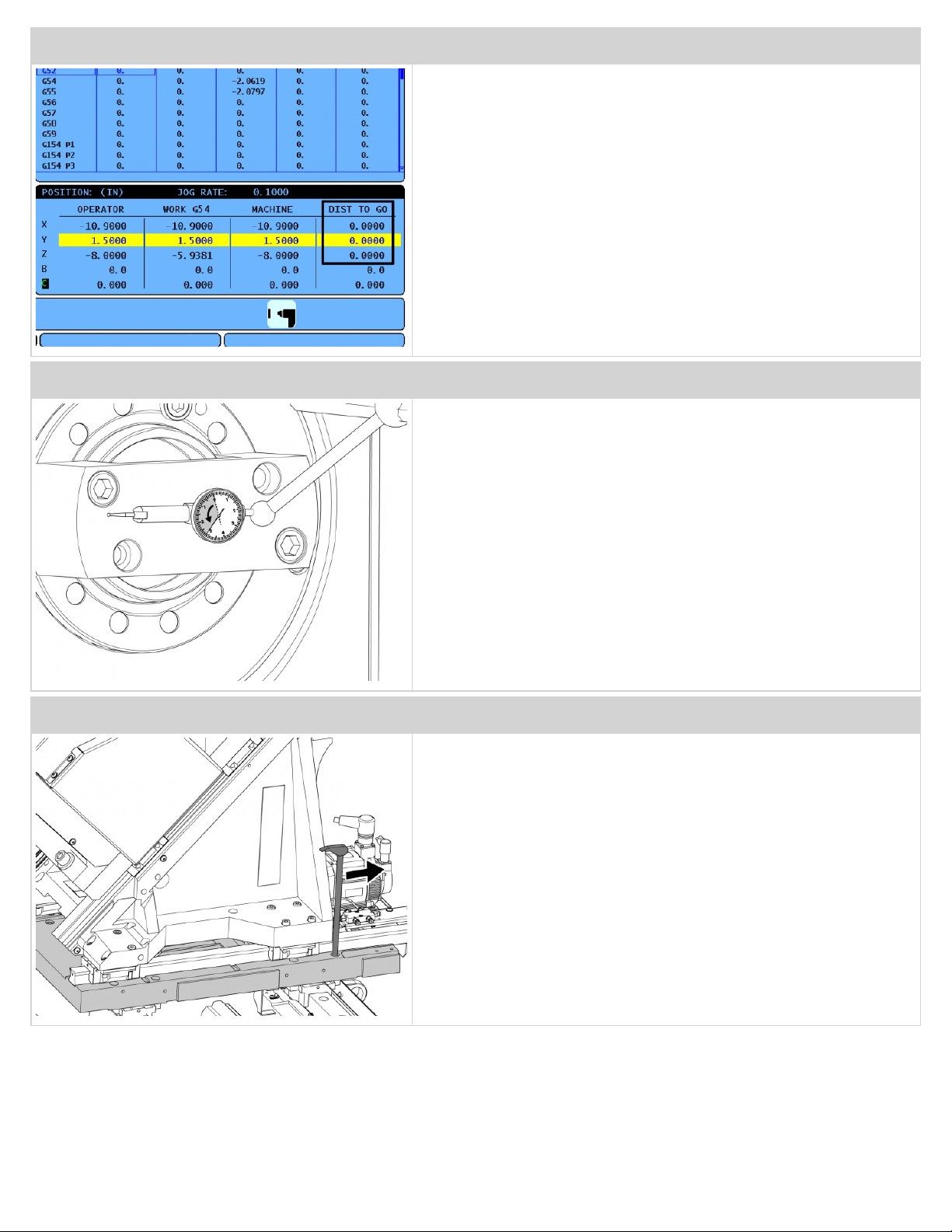

2. 0.0001-inch (0.002 mm) indicator

3. 0.0005-inch (0.01 mm) indicator

4. Spacer for the Spindle Alignment Tool (for ST-40 Big Bore only)

5. Adapter for the Spindle Alignment Tool (for ST-40 Big Bore only)

6. 0.0005-inch (0.01 mm) Coaxial indicator. The indicator shaft size must be 0.375 inches (9.525 mm), to fit into the

coaxial indicator mount (T-0017).

7. T-0017 - Coaxial Indicator Mount

8. Face Indicator Tool

9. Tailstock Alignment Tool

10. Spindle Alignment Tool

11. Optional: Spindle Head Alignment Tool (for ST-20/30, DS-30 only). To make this tool, refer to ST-20, ST-30, DS-30

Spindle Head Alignment Tool. To attach this tool you need a 1/2-13x1 flat head cap screw.

Refer to the Field Service Lathe Level and Alignment Checklist for the part numbers of these alignment tools for each lathe model.

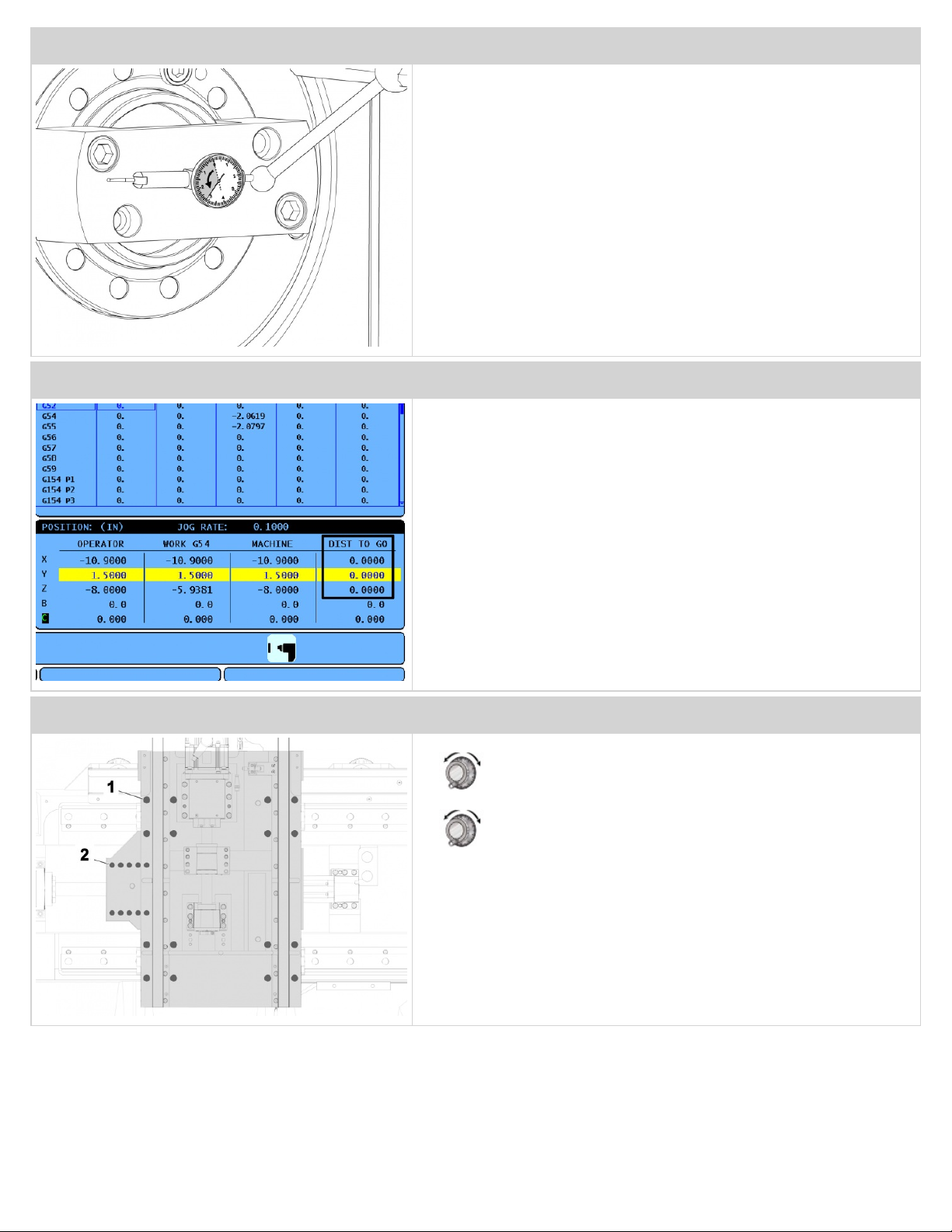

Parts Required:

(6) Rail Plugs (P/N 20-4300)