Operating instructions 4126

Flexproof-Cutter

AF-61/6x30

Page 3of 14

Edition: 01/0306 Subject to alterations

1. General information

1.1 Application

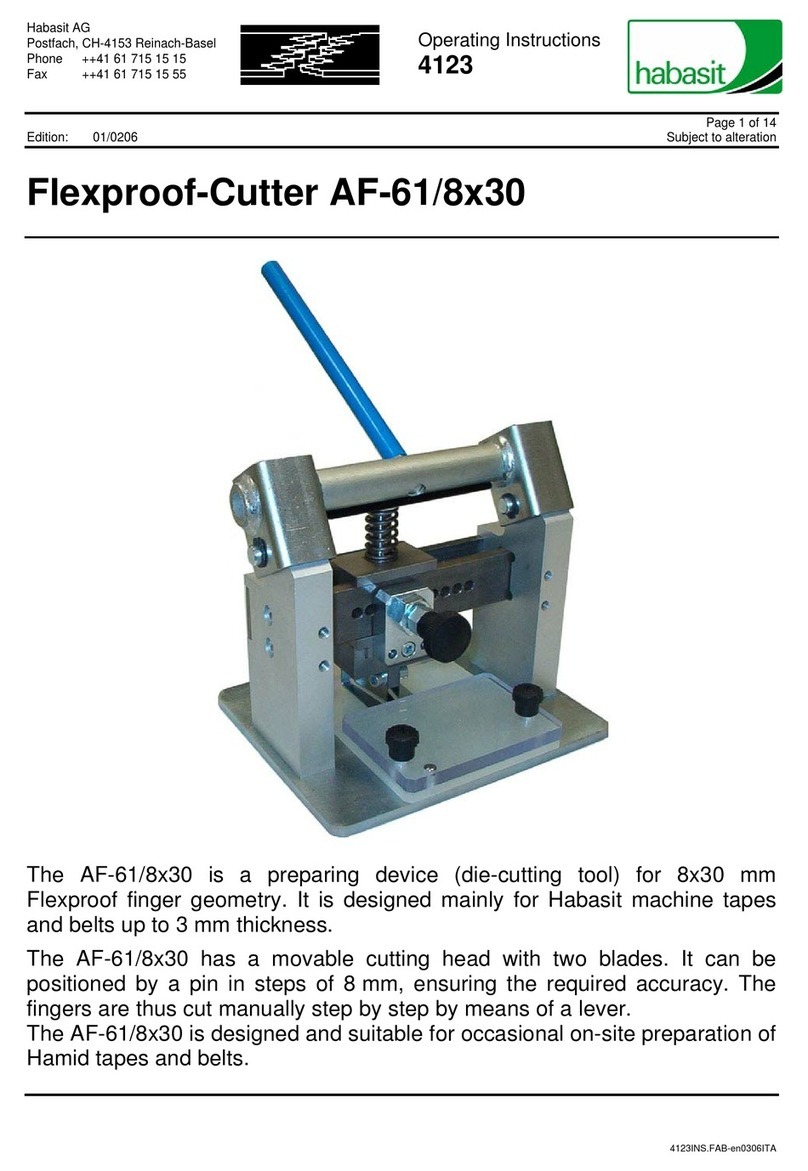

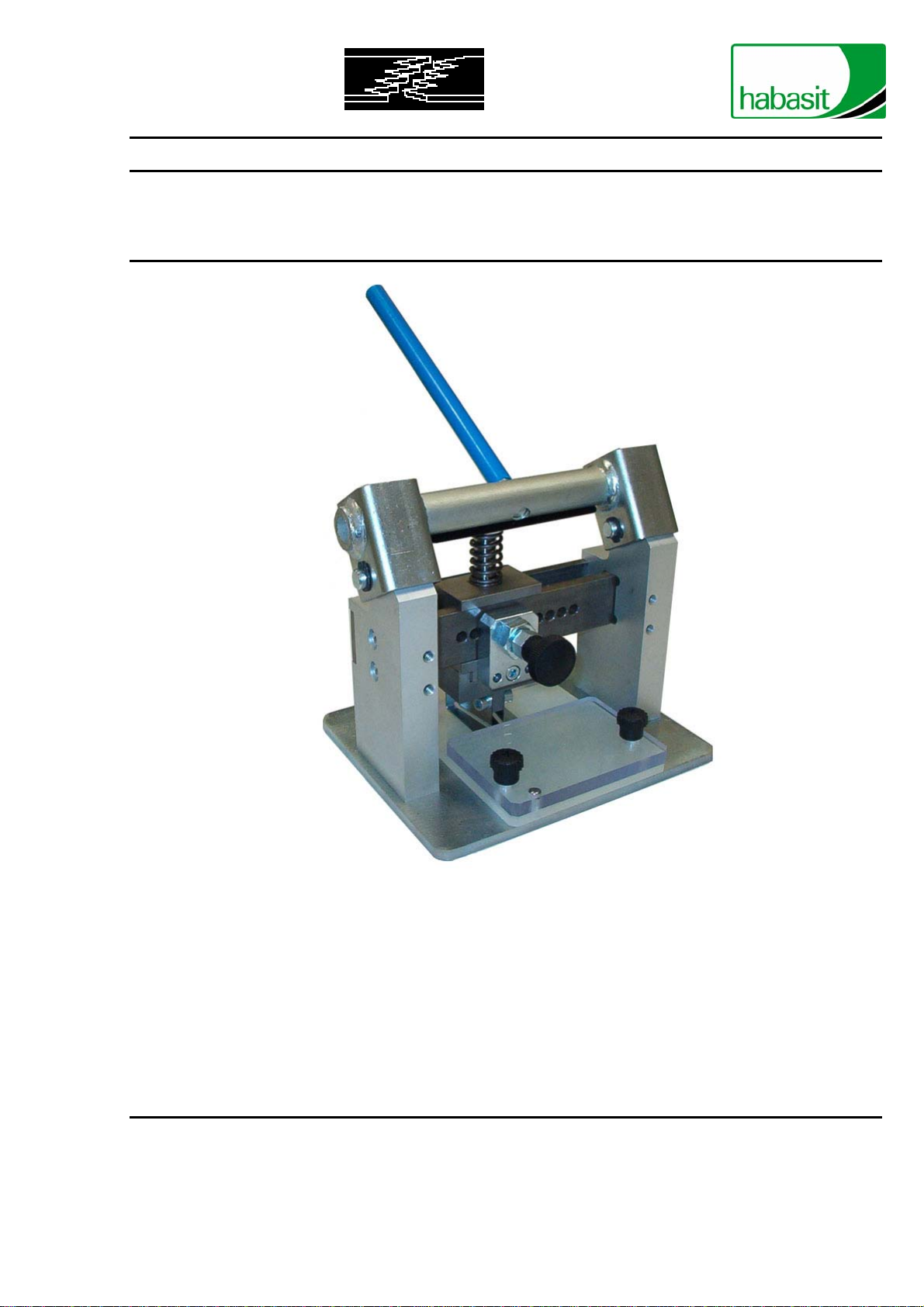

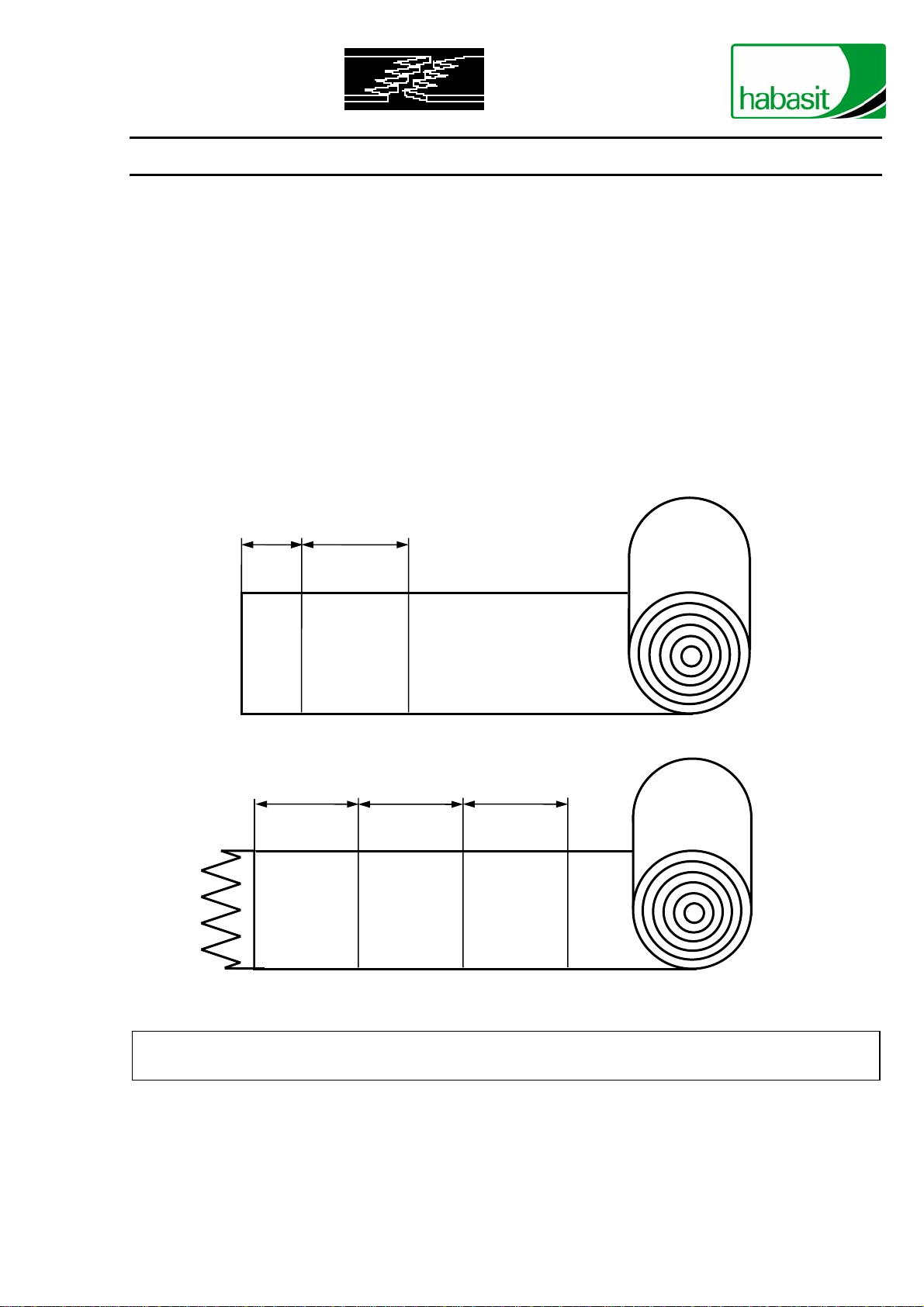

The Flexproof-Cutter AF-61/6x30 was specifically designed for the rapid and safe preparation (die-cutting) of

Habasit spindle tapes and Hamid machine tapes using the Flexproof procedure. The belts/tapes can be up

to 60 mm/2.36 in. width and 3 mm/0.12 in. thickness. It is suitable for Habasit standard finger geometry with

the pitch of 6 x 30 mm. Die-cutting is done in manual strokes‚ resulting in the most precise finger cut and

therefore optimum joint strength.

The Flexproof-Cutter AF-61/6x30 was developed solely for the purposes described in the operating

instructions. Improper use, or use for other applications than those described in the instructions, is not

permissible. Habasit accepts no liability for the consequences of improper application.

The AF-61/6x30 is manufactured according to the state-of-the-art and fulfills the EC safety regulations.

These operating instructions imply that all assembly, maintenance, and repair work, as well as operation of

the die-cutting device, be carried out by skilled personnel or monitored by responsible specialists.

For reasons of scope, these instructions cannot cover all possible aspects of operation, maintenance, or

repair. The indications given herein refer to the use of the tools according to their designated purpose by

skilled personnel.

In case of doubt or if further detailed information is required, please contact the manufacturer (Section 1.4)

1.2 Important safety terms

In these operating instructions, you will find the terms WARNING, CAUTION, and INDICATION. They signal

dangers or special information to be borne in mind.

WARNING If disregarded, there is a danger of severe injury, and/or severe material damage.

CAUTION If disregarded, there is a danger of injury, and/or material damage may be caused.

INDICATION Technical information is emphasized if it is important and not readily apparent, even for

skilled personnel.

Please observe all indications for assembling, operating, and maintaining this device, as well as all technical

data! This will prevent possible trouble and/or damage to people or materials.

Skilled personnel refers to persons authorized to perform the required work. These people have been

sufficiently trained and introduced to their field of activity so that they are able to recognize and prevent

dangers. They are aware of the pertinent provisions and safety regulations.

4126INS.FAB-en0306ITA