User Guide

TGT. 25.06.2019 Technical Page 3 of 20

©Copyright by Habegger Maschinenfabrik AG Version 04 / 25.06.2019

Contents

1General specifications ........................................................................................................................................................... 6

1.1 Drive mechanism.......................................................................................................................................................... 6

1.2 Housing cover ............................................................................................................................................................... 6

1.3 Rope.............................................................................................................................................................................. 6

1.4 Operation ..................................................................................................................................................................... 6

1.5 Electrical control system .............................................................................................................................................. 6

1.6 Limit switch................................................................................................................................................................... 7

1.7 Lowering and breaking ................................................................................................................................................. 7

2Assembly and performance .................................................................................................................................................. 8

3Safety instructions................................................................................................................................................................. 9

3.1 Proper use .................................................................................................................................................................... 9

3.2 Safety instructions in this user guide............................................................................................................................ 9

3.3 General safety instructions......................................................................................................................................... 10

3.4 Approved users........................................................................................................................................................... 13

3.5 Warranty and Guarantee ........................................................................................................................................... 13

3.6Actions in case of emergency ..................................................................................................................................... 13

4Technical specifications....................................................................................................................................................... 14

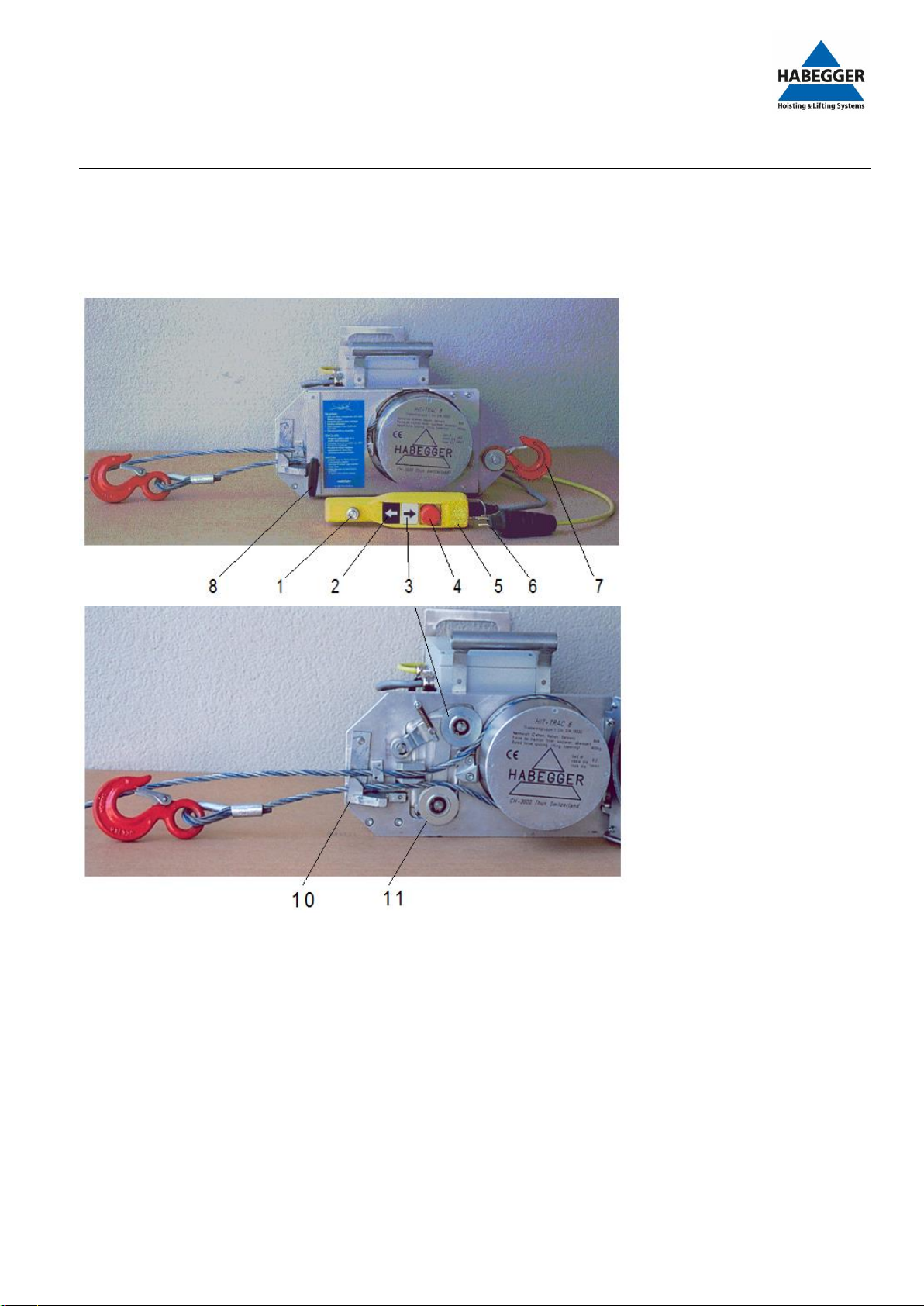

5Operation ............................................................................................................................................................................ 15

5.1 Preparation................................................................................................................................................................. 15

5.2 Insert rope .................................................................................................................................................................. 16

5.3 Pulling and hoisting .................................................................................................................................................... 17

5.4 Lowering ..................................................................................................................................................................... 17

6Faults ................................................................................................................................................................................... 18

7Maintenance ....................................................................................................................................................................... 19

8Replacement parts .............................................................................................................................................................. 19

9Disposal ............................................................................................................................................................................... 20

10 Accessories.......................................................................................................................................................................... 20

10.1 Supporting pipe .......................................................................................................................................................... 20

10.2 Storage boxes ............................................................................................................................................................. 20

10.1 Generators.................................................................................................................................................................. 20