Table of Contents

2

Section 4 Interface and navigation ..................................31

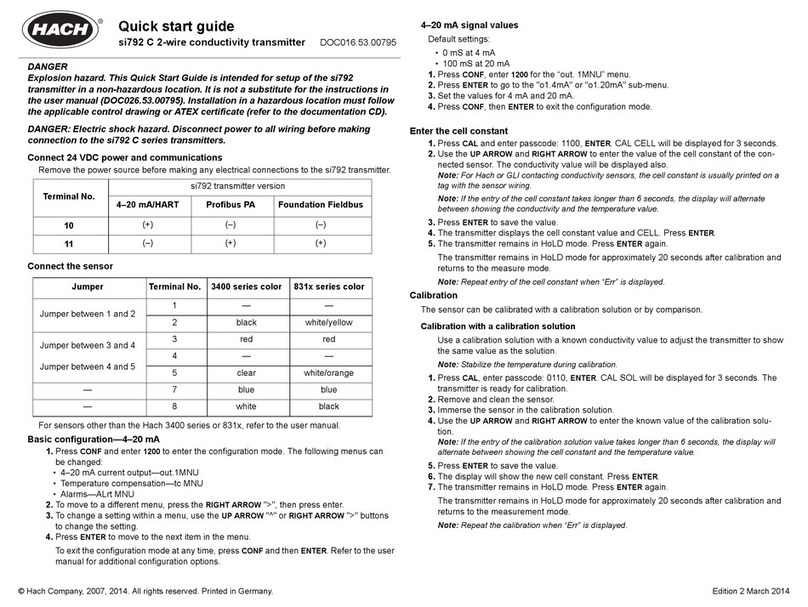

4.1 si792(x) E/T (4–20 mA/HART) interface...................................31

4.2 si792x E/T-FF and si792x E/T-PA interface .............................32

4.3 Display......................................................................................33

Section 5 Operation—4–20 mA/HART............................35

5.1 Measure mode ......................................................................... 35

5.2 Configuration ............................................................................ 35

5.2.1 Current output configuration..............................................36

5.2.1.1 Time constant of output filter......................................39

5.2.1.2 Output signal during errors.........................................39

5.2.1.3 Output signal during HOLD ........................................ 40

5.2.2 Temperature compensation configuration.........................41

5.2.3 Alarm settings....................................................................42

Section 6 Operation—Foundation Fieldbus................43

6.1 Configuration ............................................................................ 43

6.1.1 Configuration steps ...........................................................43

6.1.2 Configuration menu........................................................... 44

6.2 Foundation Fieldbus communication........................................47

6.2.1 Standard resource block (RB)...........................................47

6.2.2 Standard analog input block (AI).......................................50

6.2.2.1 Operating modes........................................................50

6.2.2.2 Set the parameter and units.......................................50

6.2.2.3 Data processing ......................................................... 51

6.2.2.4 Alarms ........................................................................ 51

6.2.2.5 Bus parameters for the analog input block.................52

6.2.2.6 Cyclic measured value status.....................................55

6.2.2.7 Measured value limits—limit bits................................55

6.2.3 Transducer block...............................................................56

6.2.4 Calibration via Foundation Fieldbus..................................63

Section 7 Operation—Profibus PA................................... 65

7.1 Configuration ............................................................................ 65

7.1.1 Configuration steps ...........................................................65