INDEX

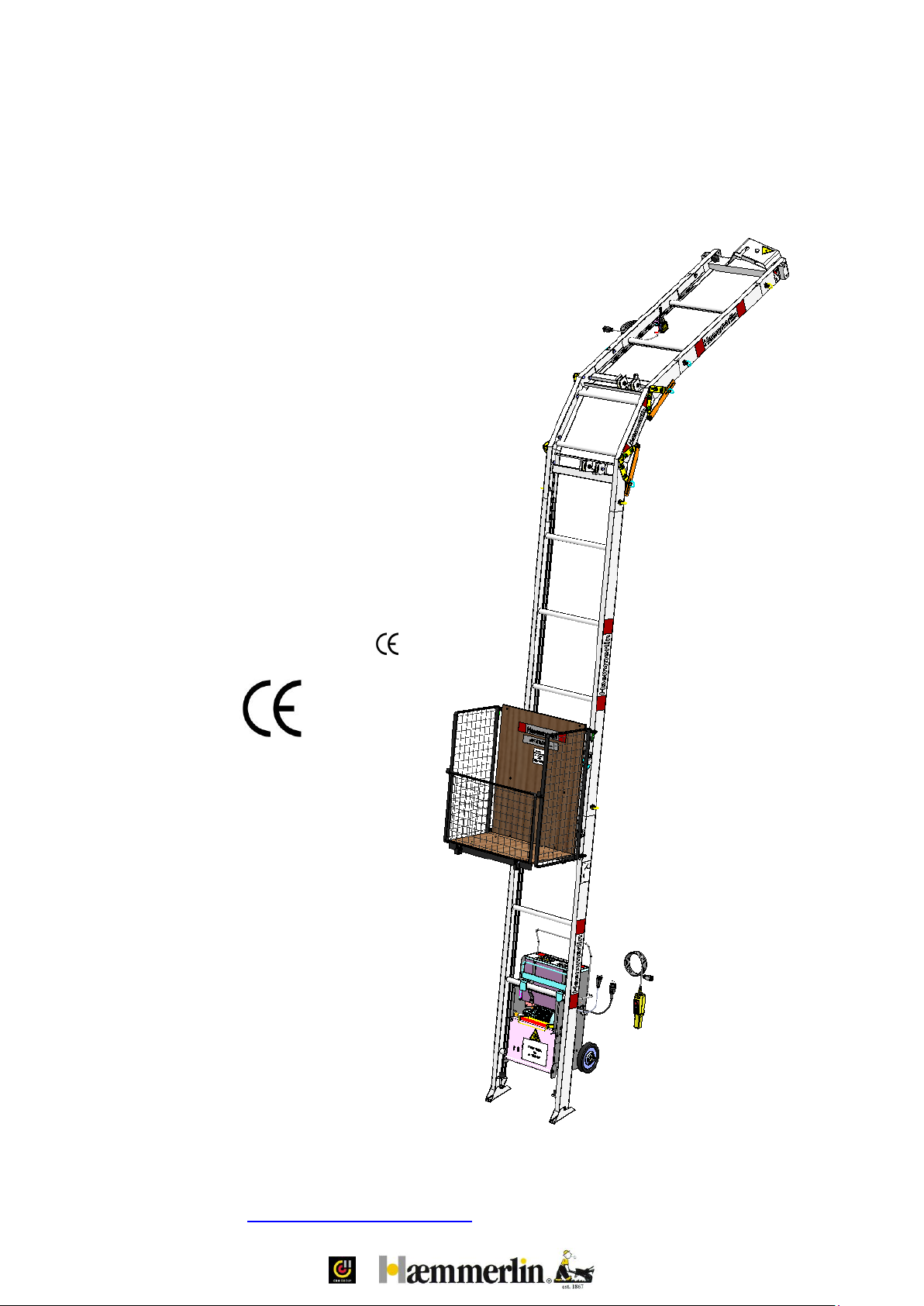

MAXIAL PREMIUM 175 basic composition ................................................................................ 3

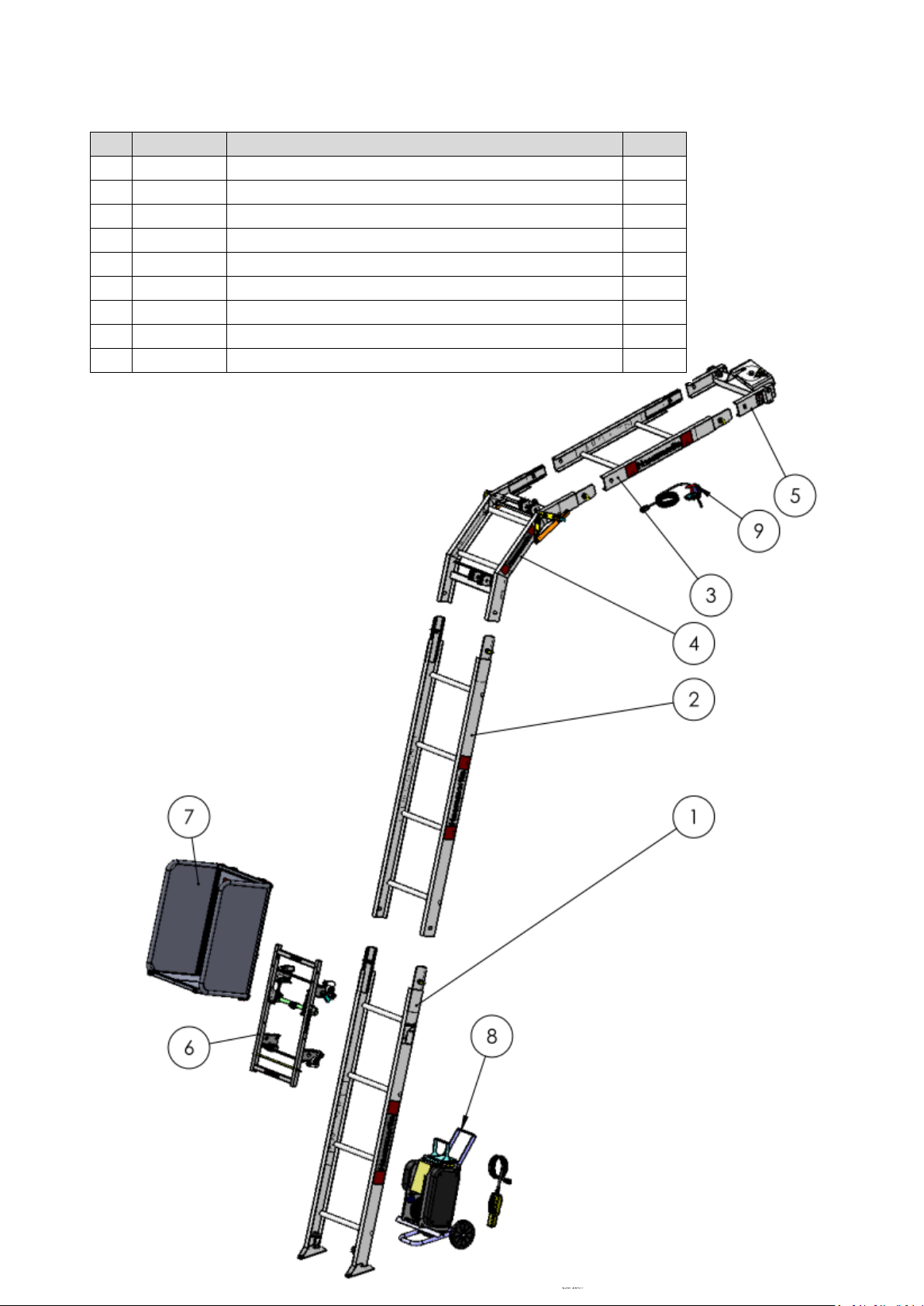

MAXIAL EXCELLIUM 200 basic composition..... ....................................................................... 4

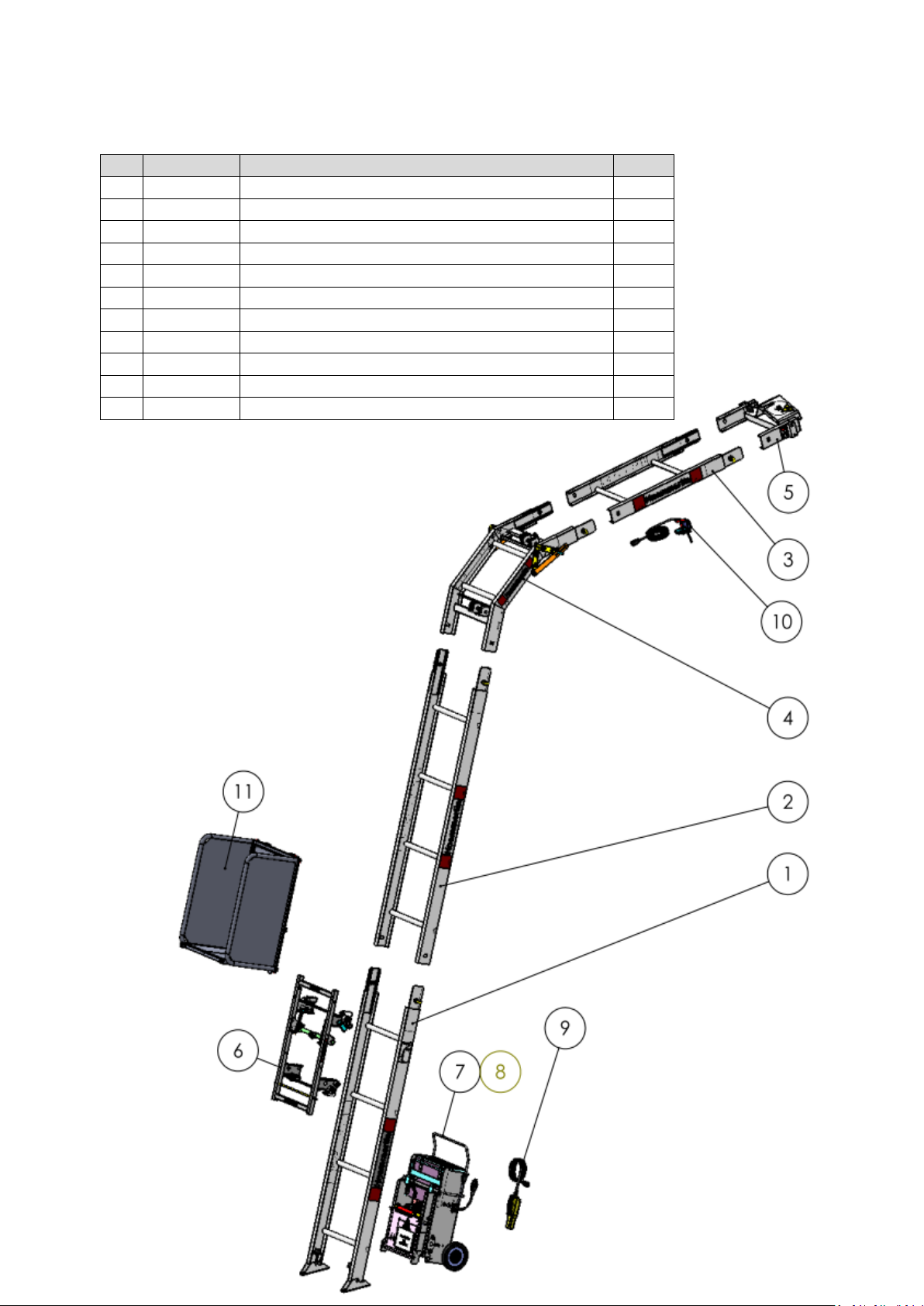

MAXIAL EXPERT 250 basic composition .................................................................................. 5

Sample EC Declaration of Conformity ....................................................................................... 6

Guarantee conditions ................................................................................................................. 7

List of all components ................................................................................................................. 8-9

Technical specifications .............................................................................................................. 10

General characteristics ............................................................................................................... 11-12

Precautions to be taken during installation ................................................................................. 12-13

Safety markings .......................................................................................................................... 14

Installation and safety instructions .............................................................................................. 15-20

Installation of electric winches:

- Winch 175 CA for Maxial Premium ........................................................................................ 21-23

- Winch 200/250 ABM-VF for Maxial Excellium / Expert .......................................................... 24-26

Installation of the upper limit switch on the ladder ...................................................................... 27

Installation of the guide hooks for the upper limit switch electrical cable .................................... 28-29

Installation of the lifting cable ...................................................................................................... 30-32

Installation and use of accessories:

- Roofer platform ....................................................................................................................... 33

- Universal platform .................................................................................................................. 34

- Double tipping bin .................................................................................................................. 35-40

- Tipping skip ............................................................................................................................ 41-43

- Horizontal/vertical sheet carrier .............................................................................................. 44

- Renovation platform ................................................................................................................ 45-49

Inclined shoring ........................................................................................................................... 50

Examples of inclined installations of the hoist on the façade of a building .................................. 52

Installation and use of shoring accessories:

- Base ladder prop 2 to 3m ....................................................................................................... 52-53

- Extension prop 2m .................................................................................................................. 53

- Bumper prop 1.5 to 2.5m ........................................................................................................ 54-55

- Pair of headboard props ......................................................................................................... 56

- Complete trestle with fixing clamps ........................................................................................ 57

Vertical anchoring ........................................................................................................................ 58

Examples of vertical installations of the hoist on the façade of a building ................................... 59

Installation and use of accessories for anchoring against a building:

- Enclosure clamp ...................................................................................................................... 60-61

- Balcony clamp ......................................................................................................................... 62-63

- Mooring cylinder ...................................................................................................................... 64-66

Vertical installation against the façade of a building using clamps .............................................. 67-68

Examples of vertical installations of the material hoist against scaffolding .................................. 69

Installation and use of accessories for anchoring against scaffolding:

- Tube, couplers and VE fixing clamps ....................................................................................... 69-71

Vertical mounting against scaffolding using VE fixing clamps ...................................................... 72-73

Dismantling the hoist ..................................................................................................................... 74-75

Regulations and safety instructions ............................................................................................... 76-79

Maintenance .................................................................................................................................. 79-81

Repairing Maxial electric winches ................................................................................................. 82-83

Electrical diagram of 175CA winch for Maxial Premium ............................................................... 84

Electrical diagram of 200/250 ABM/VF winches for Maxial Excellium and Maxial Expert ............ 85-86

Guarantee form and/or after sales service .................................................................................... 87