PAGE 29 OF 9

POSSIBILITY OF DANGER ON THE MACHINE

On ASYMMETRICAL 3 RollerBending Machines, safety measures towards

danger are Taken. For example:

The electric installation has a metal closure.

Other dangerous part is the place where rolls rotate. By wrong and careless use,

dangerous situations may arise. During working, safety rope is mounted

around the machine towards accidents.

DAMAGE CAN HAPPEN

-User operator's fingers or hands

-User operator's clothes or other

subjects

-Deformed working material

-The third person when material

is bending

-Machine bending equipment....

All staff who run, install and maintain the machine are responsible to read the

warnings and apply the instruction manual. Do not attempt to bend hard

materials except form metal or aluminium sheet. You may give harm to either

the machine or yourself. To make modificition on the machine is forbidden

because of safety and productivity. Working maintenance and safety factors in

the instruction manual are supposed to be obeyed and applied.

FUNCTIONS OF THE MACHINE

Asymmetrical Bending Machines are produced to shape material and their

functions are shown below

This machine has the ability to bend closed and semi-closed pipes and conics.

Our machines are produced in different capacity and dimensions depending on

the thickness of the material bent Check sheet thickness on page 5 before

starting to bend material. Do not attempt to bend material that is larger than

indicated sheet thickness or quality.

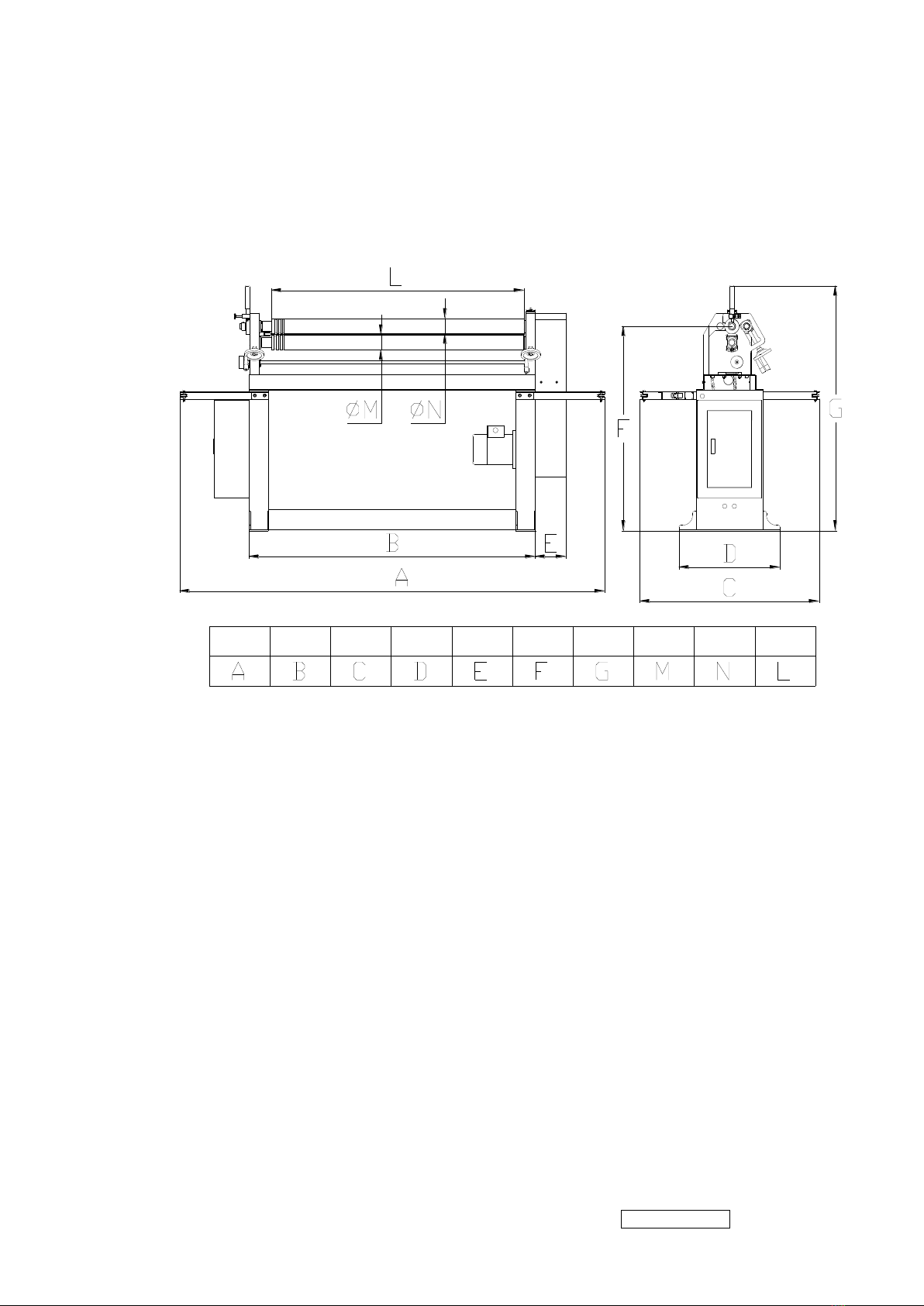

To identify Asymmetrical Bending Machines, roll diameter, width of the bending

material and thickness of it are indicated.

For exampkle PR-132H 75 x 1300 x 2

PR-132H = Machine Type

75 = Roll diameter

1300 = Bending material width

2= Thickness of material (mm) that is 1,5 times larger than roll diameter

These values are valid for materials in St-37 quality.

Yield Pressure = 90 N/mm2

Straight Pressure = 130N/mm2