HAFNER Pneumatik Krämer GmbH & Co. KG

Stammheimerstr. 10 | D-70806 Kornwestheim

Tel.: 07154 / 178589-0

Web: www.hafner-pneumatik.de

3

After connecting the electrical connector, tighten the retaining screw to the correct torque.

If a problem is detected when connecting to the socket (e.g. dirt, bent contacts etc.), the cause must be

rectified.

During operation, make sure that the maximum permissible temperature at the connection is not exceeded.

Defective devices cannot be repaired.

The cable connections must be free of dirt and corrosion.

It is forbidden to unplug or forcibly insert the plug from the power supply.

Protect electrical connectors from dirt, aggressive substances (e.g. acids, alkalis, gases etc.), moisture and

from not allowed temperatures.

The connectors must be cleaned regularly. Use an antistatic cloth for cleaning. Disconnect from the power

supply before cleaning.

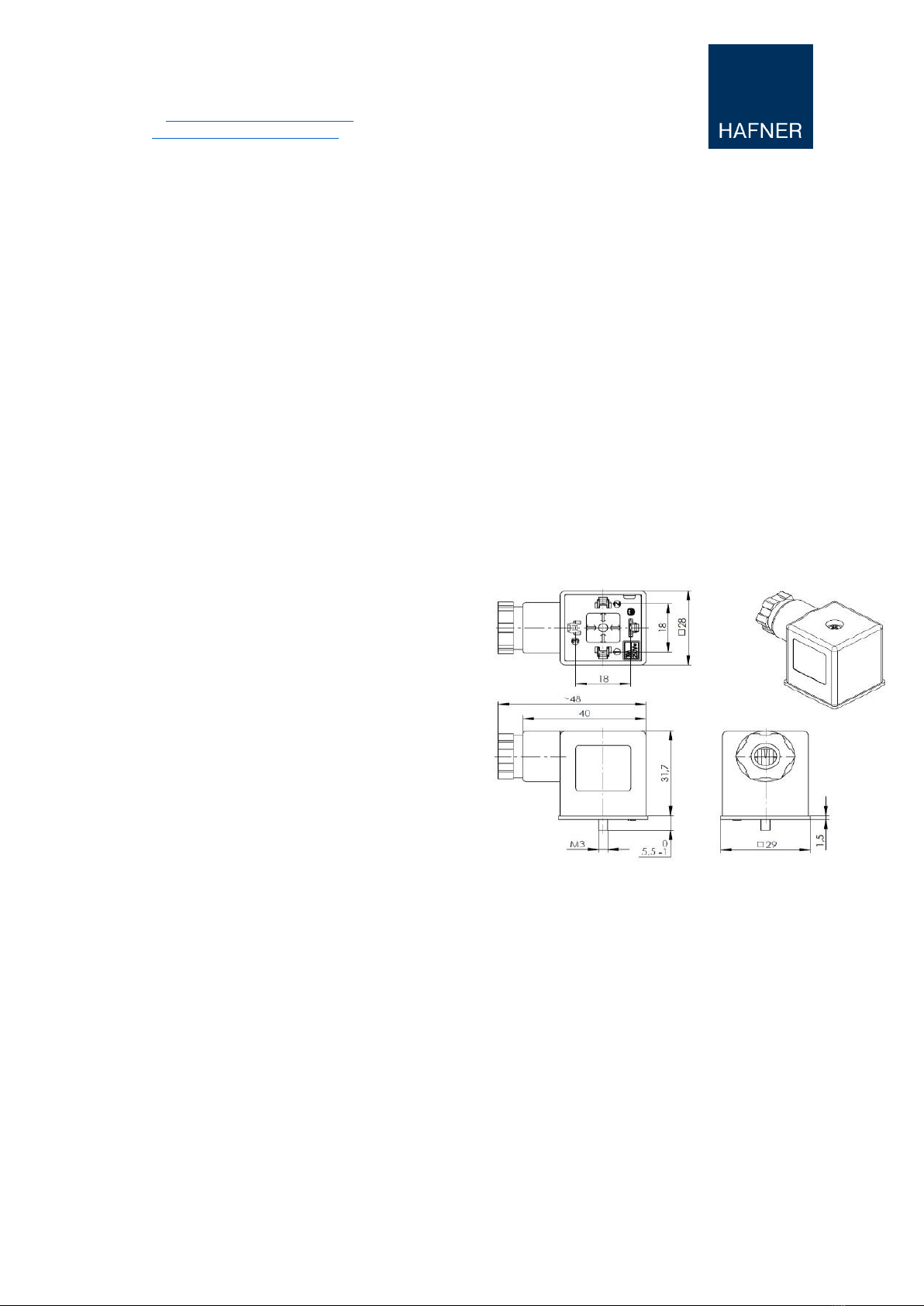

Form A

Housing Material: PA6 GF30

Cable gland thread: M20x1,5

Cable diameter: 6-8mm

Tightening torque: 1,8 ± 0,2Nm

Poles: 2 + PE

Direction of protecting earth: 12 h

Contact distance: 18 mm

Contact material: CuZn, tin-plated

Resistance: < 15mOhm

Conductor cross-section: 0,5-1,5mm2

Max. tightening torque: 0,3 Nm

Wire protection: use of wire end

sleeves is recommended

Gasket type: flat

Fastening screw material: steel 4.8, zinc-plated

Fastening screw size: M3 x 33,5mm (with cross recess)

Fastening screw

tightening torque: 0,4 ± 0,1 Nm

Voltage: 0 –250 V + 15%

Ambient temperature range -25°C - +90°C