Haier HDU-42CH03 User manual

Other Haier Air Conditioner manuals

Haier

Haier AP88NACAAA User manual

Haier

Haier HPAC99ER User manual

Haier

Haier 1U25S2SQ1FA User manual

Haier

Haier HSU-09LD03 Operation and maintenance manual

Haier

Haier HW-24CE03 User manual

Haier

Haier AS09GS1ERA User manual

Haier

Haier QHQ06 Operating instructions

Haier

Haier HM-09CB03/R1 User manual

Haier

Haier HSU-040C01 User manual

Haier

Haier D Series User manual

Haier

Haier AS072AZBAA User manual

Haier

Haier HWF05XC5 User manual

Haier

Haier HSU-09LEK13/R2 Installation manual

Haier

Haier HWR08XC5-T User manual

Haier

Haier HSM0912HEA03 User manual

Haier

Haier Super Match AF09AS1ERA User manual

Haier

Haier Platinum Series User manual

Haier

Haier HWE24VCN User manual

Haier

Haier AS09PBMHRA User manual

Haier

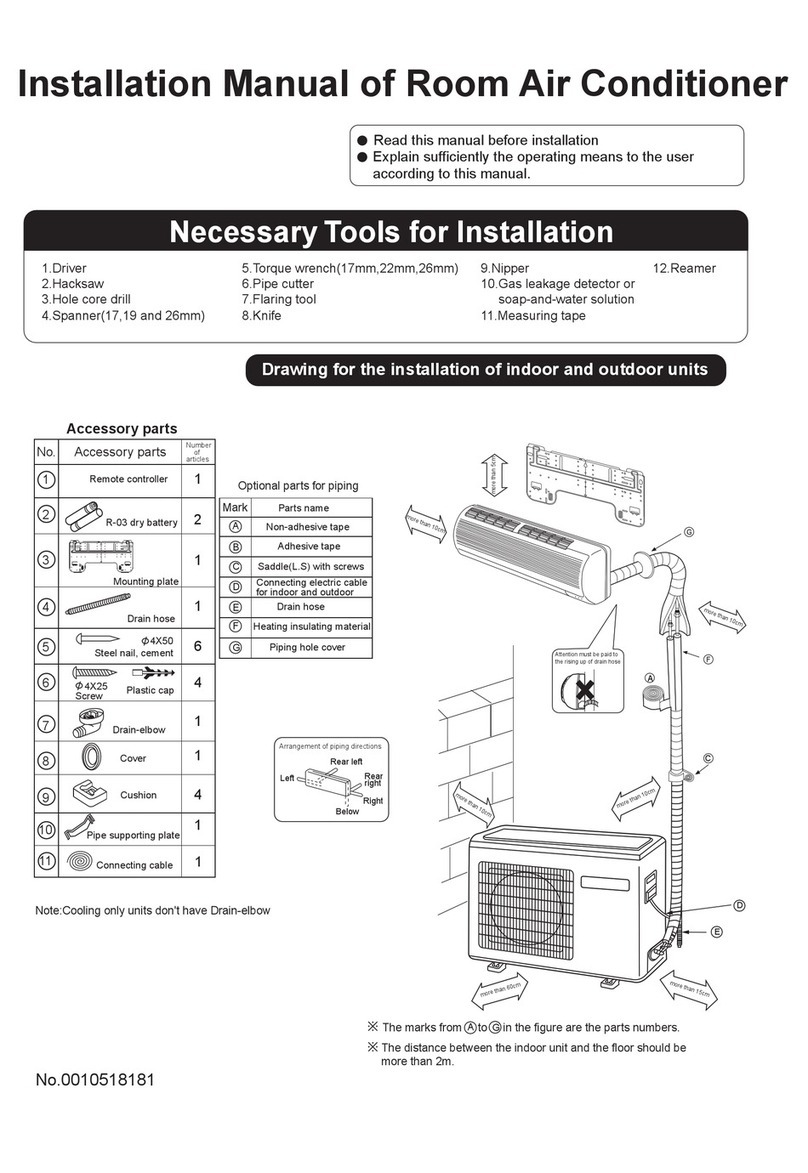

Haier 10518181 User manual